Okuma V System : The Review

Hello again

In the tackle world there are questions that get asked frequently. The most frequent one no doubt is "Stella or Saltiga?", and if you ask me about the second most asked question I'd say it's "Quntum Cabo or Okuma V-Syatem?", followed maybe by "Van Staal or ZeeBass?". I tried my best to answer the Stella/Saltiga question over two generations of models, and in this review I'll be tackling the Cabo/VSystem one. I originally had planned to do a single review of the two reels head to head, but Quantum have recently redesigned the Cabo and the new reel isn't on the market yet, so this review will be Part#1 of the duel, to be followed by Part#2 once the new Cabo is released and I get to fish it for a while. Naturally both reviews will be of size 80, the biggest size both reels are available in.

Unknown to many is that the reel comes in two gear ratios, with an "S" included in the model name of the speedy reel. For example V80A has a 4.8:1 gear ratio, and V80SA has a 6.2:1 ratio. Same goes for smaller sizes as well. This makes the VSA the second of two affordable high-speed offshore reels available from a mainstream manufacturer, the other reel being the Daiwa Saltist spinning. The high speed VSystem is not sold in the USA tough.

What comes with it

It comes with a spare spool, manual and warranty flyers, spool shims to change the line lay pattern, a crappy soft reel bag, and two spare shafts (red arrows) that I'll explain later. I bought mine at the $200 retail price in July, but I regret not checking Amazon first since I saw them last month going for $144 over there. This is by no means my first V-System. I've used them for many years, but these reels have gone through several updates and changes, so I naturally wanted to review the latest version.

The advertised weight on Okuma's site is 24.6oz (697 grams), which is pretty accurate according to my faithful scale. The advertised maximum drag is 33lbs (15kg), which the reel achieves with ease and even exceeds. When I test the maximum drag pressure of a reel I stop once it successfully reaches the advertised figure because there is no point in pushing it further then breaking it, but I'd say that the V80A is good for about 5 extra pounds (~2kg) of drag pressure over the advertised maximum. The spool took about 210 metres (~230 yds) of PE-8 line (0.47mm thickness), slightly less than advertised capacity.

Here is a list of the reel's features from Okuma's literature:

Ergo Grip

ALC: Alumilite construction

DFD: Dual Force Drag System

Hydro Block water tight drag

EOS: Elliptical Oscillation System

EEB: Extreme Element Bearings

RES II: Rotor Equalizing System

EFR II: Even Flow Roller System

Nope, I'm not turning into one of those who write cheesy sales pitches disguised as "reviews" in magazines/web using the manufacturer's words. I'm just reciting the advertised list of technologies in the reel so you can follow me as I discover them one after another. Also, the reel has 15 ball bearings (12 in sizes 15 & 20), which is the highest number of ball bearings in any reel in current production by a mainstream brand.

The drag

The upper stack has 3 drag washers made of felt (red arrows), which is a classic smooth drag material, but it's not the best choice for high drag settings where a lot of heat would develop. The spool uniquely runs on 3 ball bearings (blue arrows), not just 2.

Above is a closeup on one of the drag washers showing how it's beginning to acquire a yellowish shine. That's the effect of heat, and you can feel how the washers were becoming rougher as the drag saw more action. I would've loved to see carbon fibre washers instead of felt in the larger sizes of this reel, 65 and 80. Overall the drag remained considerably smooth after many runs by good sized groupers and AJs, but the performance wasn't quite the same as it was before those surface burns began to develop on the washers.

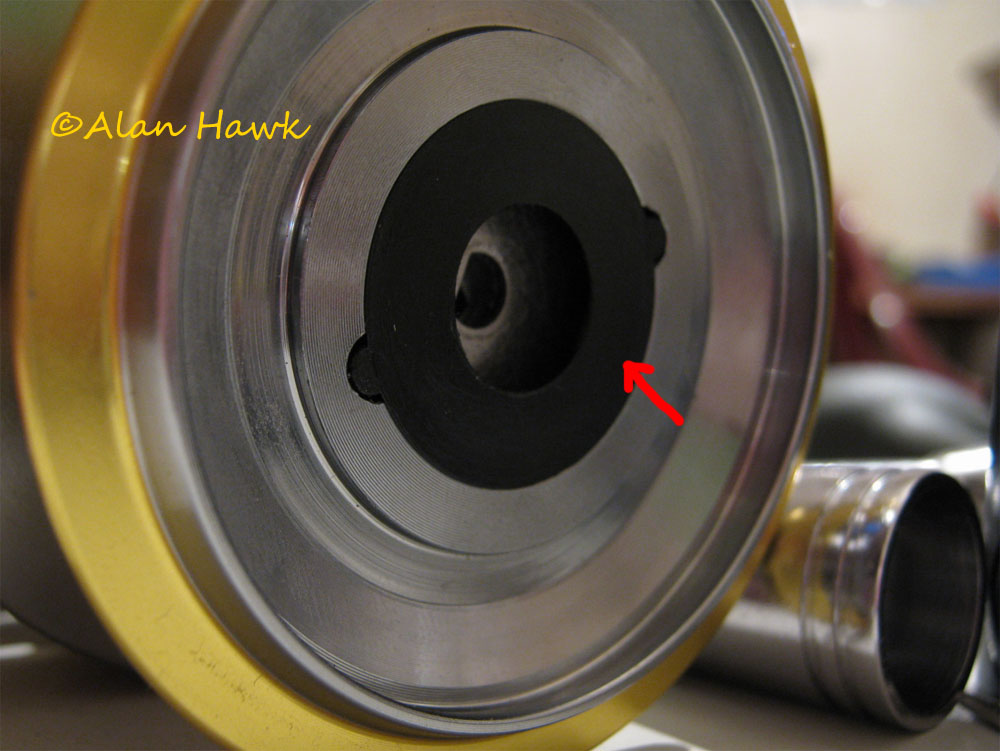

This is the large bottom drag washer beneath the spool, made of felt as well, but the effect of heat on it was much less due to its size and location. The drag clicker (red arrow) is quite durable and very audible on a noisy boat. This ladies and gentlemen is the "Dual Force Drag System"; a basic top and bottom drag setup that's becoming more commonplace these days on budget reels.

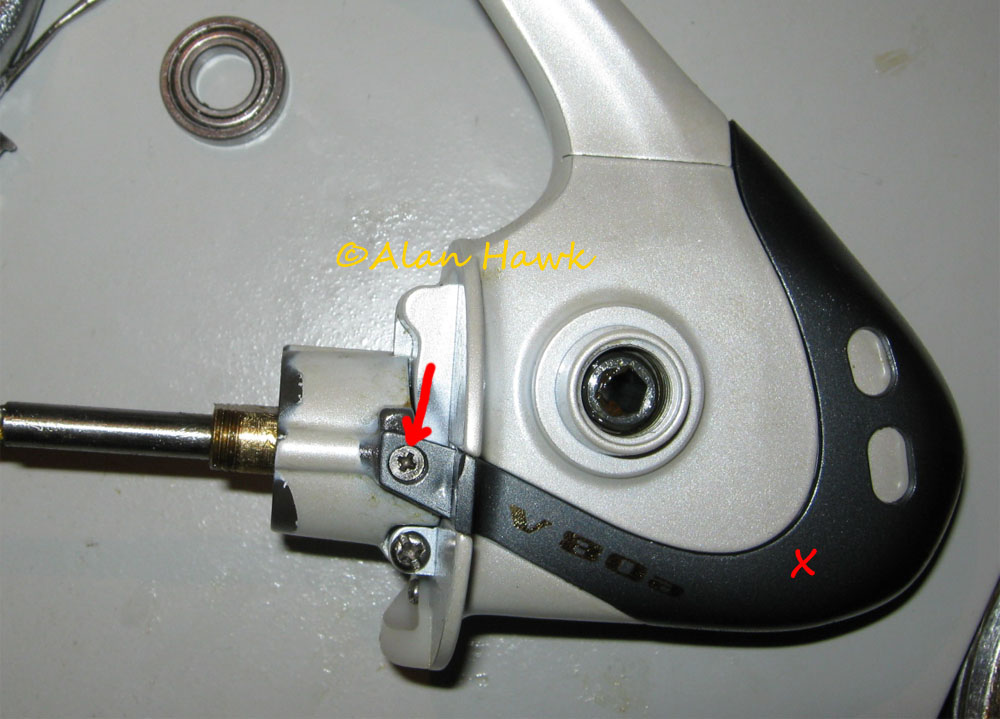

This is the drag knob. Simple plastic construction with a keyed pressure disc (red X). One of two screws of the knob had a damaged head (red arrow) due to the use of cheap screws that are easily deformed. After I took this photo I tried unscrewing the other screw but the head started deforming as well so I left it alone. That's a new one! Never seen a reel that had screws with such serious quality issues.

The red arrow points the rubber seal that protects the upper stack from water intrusion. There is no mounted seal on the knob itself nor any protection whatsoever to the bottom drag washer. So the "Hydro Block Water Tight Drag System", which sounds like some ultra sophisticated electromagnetic forcefield, is nothing but a sad looking rubber washer that barely protects the top portion of the drag. NICE!

The "ALC Alumilite Construction" is a standard aluminium-silicon alloy body similar to that found on nearly all low cost metal bodied reels. There is no special lightness to it and it's just another fancified name for a basic feature.

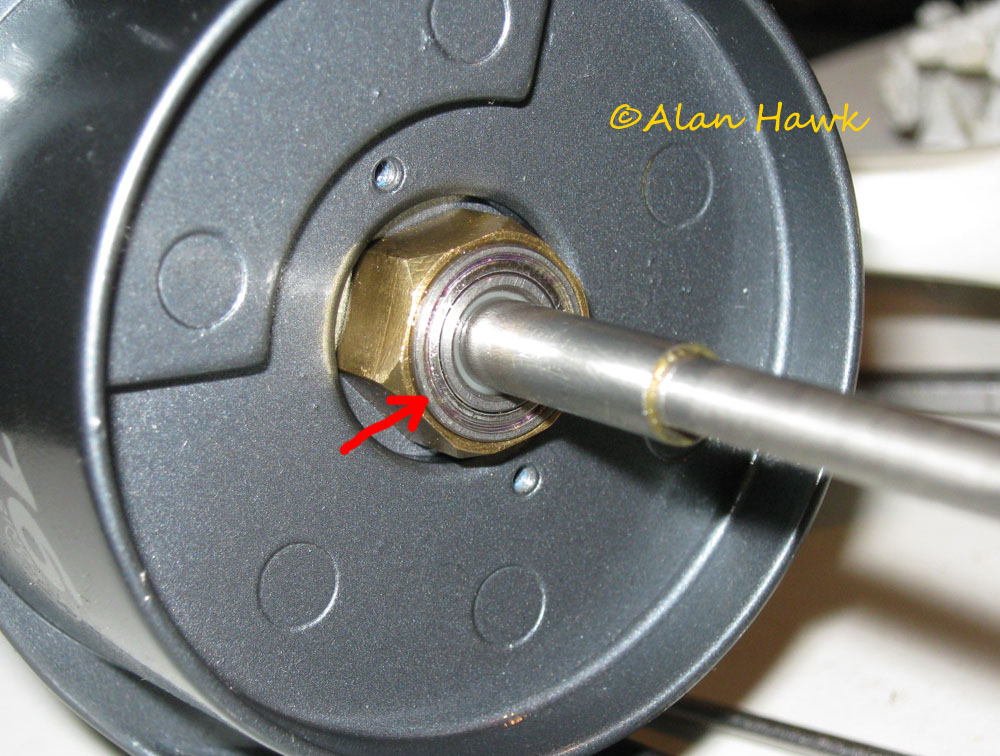

The main shaft is floating. That's a design that's been widely copied from the early Stellas, in which the shaft is borne on a ball bearing (red arrow) inside the rotor's nut to prevent the main shaft from coming in contact with the rotating pinion. This in my opinion is an indispensable feature in any offshore reel as it reduces the disruptive friction when the reel is loaded in a way that is felt and quite significant.

Removing the rotor

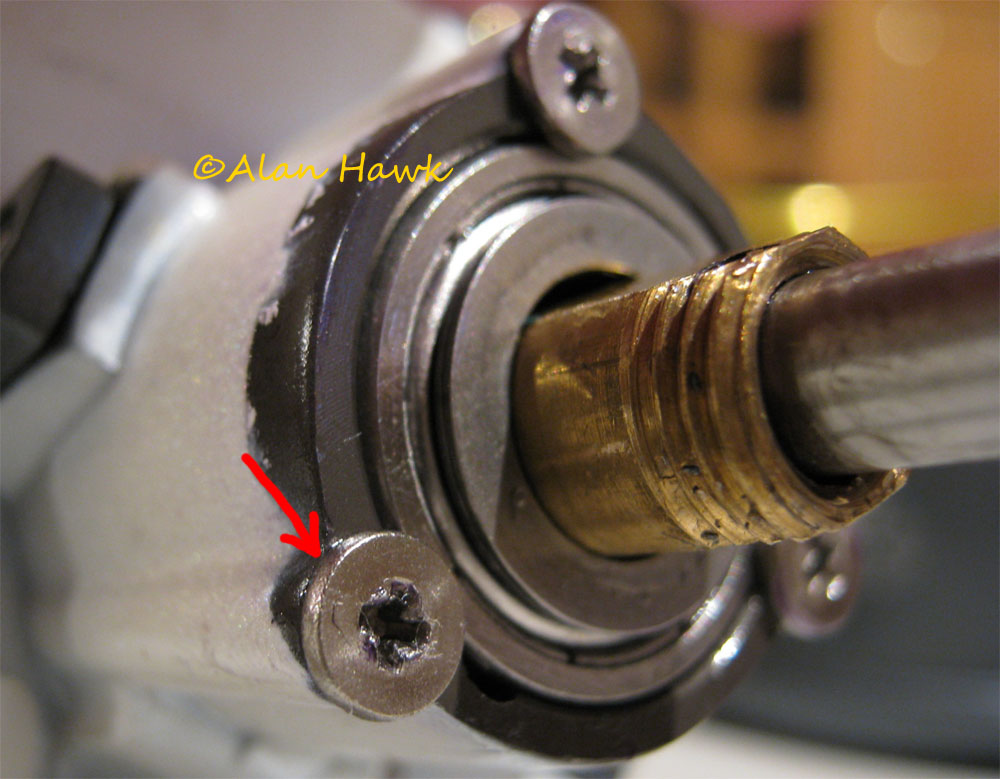

One of the three screws holding the pinion/clutch assembly had a deformed head as well (red arrow) and was a pain to remove.

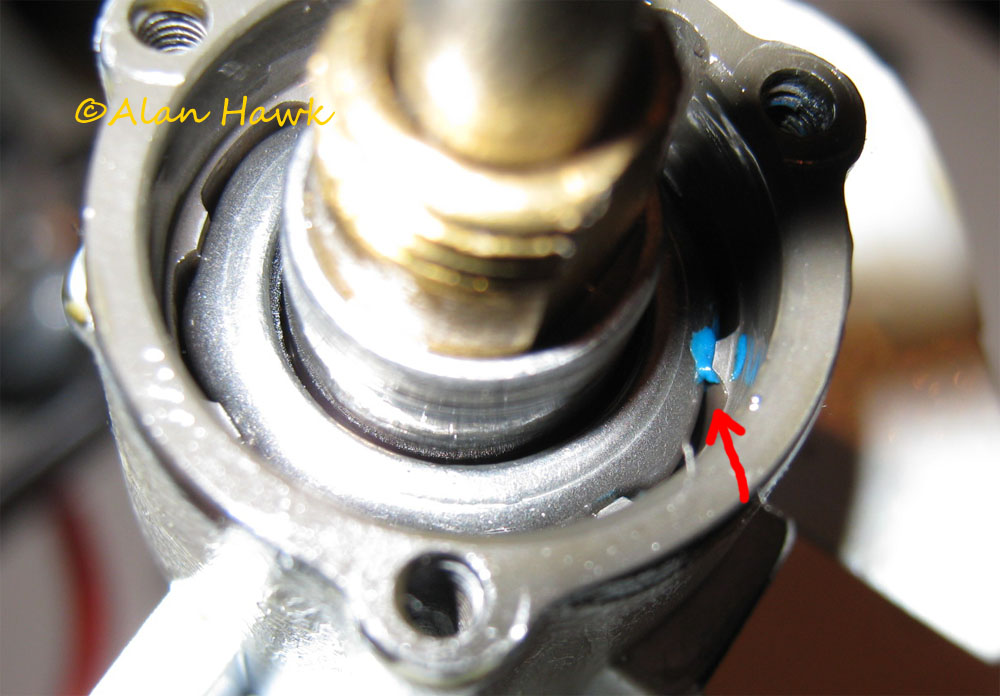

The anti-reverse clutch is fixed in its housing by blue Loctite!

The clutch was firmly glued to the frame by that Loctite and I struggled to free it, only managing to do so after I ground down a vice grip to form a thin clamp that fits behind the nut to pull without damaging the nut or the pinion itself. That's a $12 pair of pliers completely ruined

The clutch itself proved reliable and gave zero problems. Basic construction with plastic V springs and generally feels better made than the clutches of early V System reels.

The body bumper (red X) is made of good quality plastic, it extends across the entire body and is held by two screws behind the rotor (red arrow).

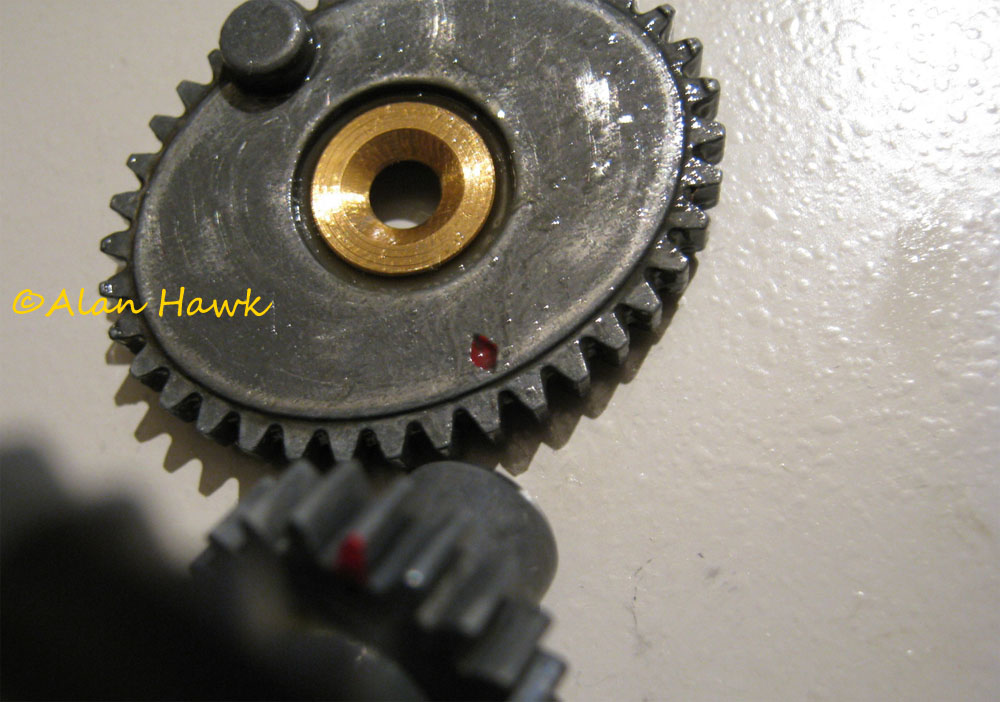

This is the "EOS elliptical oscillation system". The back oscillation gear takes the shape of an ellipse, and there is a red dot on both oscillation gears to tell you where exactly they should mesh together when the reel is reassembled. A mistake here could destroy the entire gear train. You've probably already heard loads of rubbish about this setup and its advantages, but the reality is it has absolutely none. It gives a varied rate of movement to the spool as it cycles up and down so that the spool moves slower in the straight stage of the oscillation stroke, then it moves faster when the spool is near the top and bottom, and it's fastest during the two changeovers at the very top and very bottom (when the spool changes its direction of movement from up to down or vice-versa). This sounds nice on paper, but due to the dimensions of the gear the difference in speed is pretty much negligible and there isn't a tangible advantage to the way the VSystem lays line. There are other designs that create a varied rate of oscillation in simpler ways, such as the common curved channel in the back of the oscillation block, demonstrated in the following photo

Above is the back of the oscillation block of an Abu Garcia Soron, and this curved channel design has the added advantage of making the spool stroke longer. The oscillation block of the Okuma V System has a regular straight channel. So, once more, the EOS is nothing but a fancy gimmick that only complicates the life of anyone trying to service the reel. Aligning the two red dots on the gears is not as simple as it sounds.

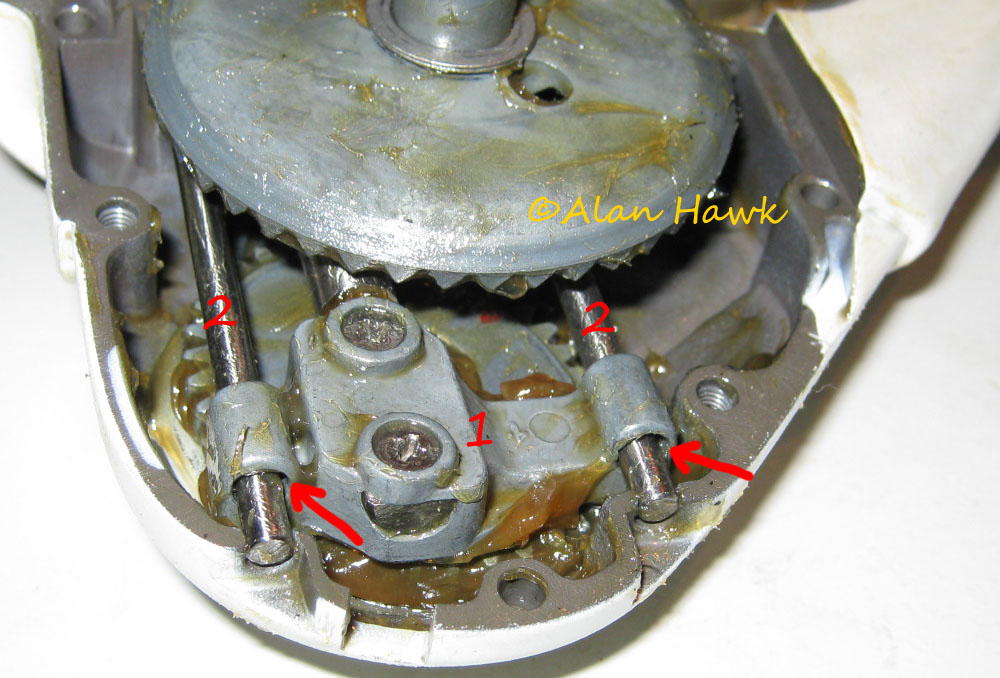

The oscillation block (#1) is mounted on two stainless steel rods (#2) in another design that first appeared in early Stellas. If you look closely you can see that the holes are much larger than the rods (red arrows) which creates play. The play there isn't felt because of the bearing in the rotor's nut (floating shaft), but the reel could have been much smoother had the tolerance here been less sloppy.

The drive gear

The die-cast drive gear is made of a zinc-aluminium alloy with a surface finish for corrosion resistance.

This gear proved to be resilient, held up well, and close examination shows relatively little wear that has a good spread over about 80% of each tooth's surface. This figure indicates how much of the tooth's surface comes in contact with the pinion's teeth during operation, and the higher it is the better the gear is designed and the more able it is to withstand loads and wear.

A good quality machined brass pinion that runs on two ball bearings.

The red arrow points to the bail trip strike. This is the part responsible for the automatic closure of the bail, and removing it converts the bail to manual operation. Pretty simple procedure that should take no more than 5 minutes.

The handle

The handle's attachment would appear to be a straightforward screw-in design, but in reality it's a more complicated affair.

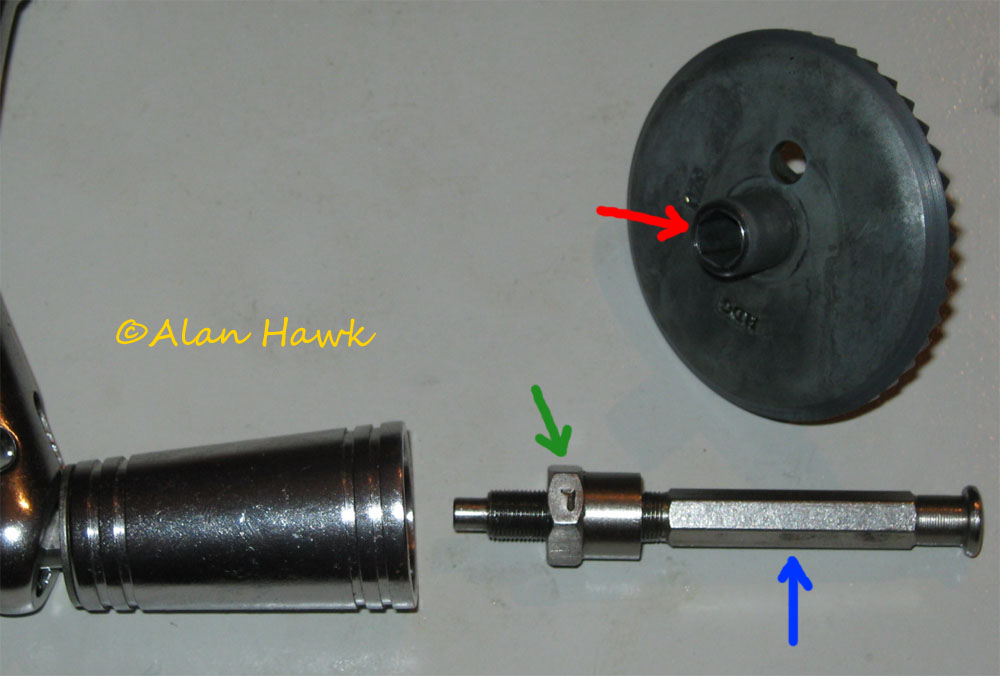

The drive gear has a female hex tube (red arrow) through which a male hex shaft is inserted (blue arrow), then it's secured by a nut (green arrow) before the handle can be screwed in. The nut is stamped "L" indicating "Left".

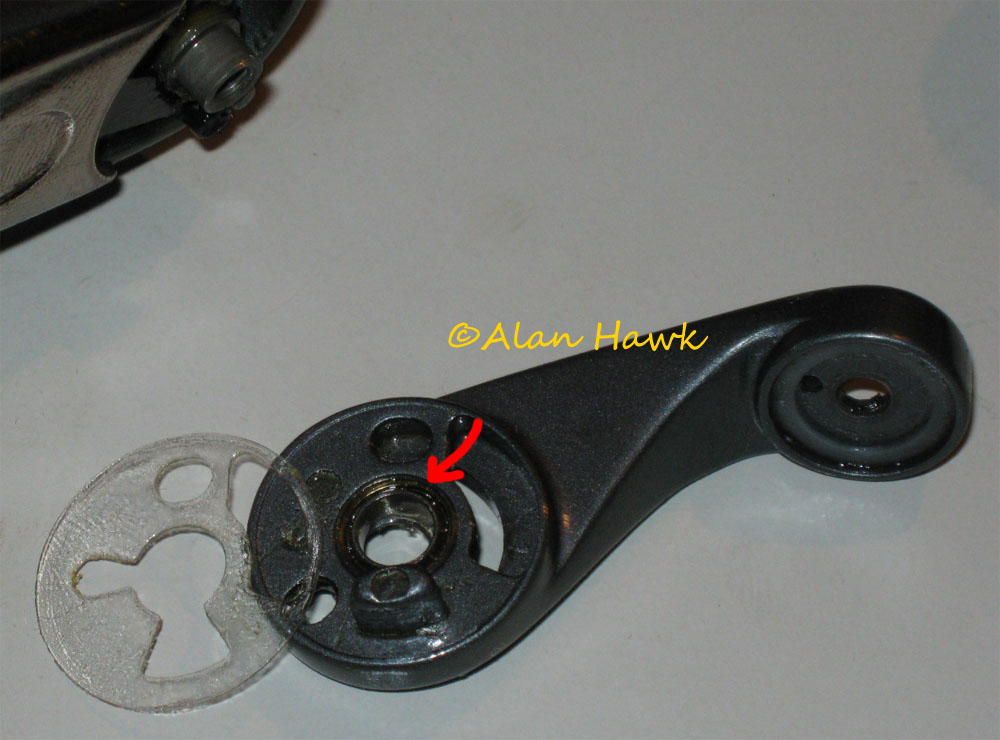

The aforementioned spare shafts that come in the little plastic bag are needed to change the handle from left to right winding. You need to unscrew the nut stamped "L", remove the male hex shaft from the gear, then insert the spare shaft (red arrow) from the other side and secure it with the spare nut stamped "R" (blue arrow), and that would be only half the job! After you do that you will have to disassemble the handle itself and replace the female threaded tube stamped "L" with the spare handle shaft stamped "R" (green arrow), and only then you can attach the handle to the other side!

If you're now thinking that no one in their right mind would design such a horribly complicated system for changing the winding side, you are right, because it wasn't originally designed like that. As the VSystem evolved and changed over the years the handle design changed significantly. Originally the male hex tube was permanently attached to the handle and you would just insert it in either side of the body then secure with a screw, as in many of the reels you probably own now. But that's an inferior design that causes play and needs constant re-tightening, so Okuma decided to upgrade it to a screw-in handle design. Unfortunately though instead of changing the drive gear design to give it a threaded axle, they devised that ultra complicated system for the sake of not having to redesign the gear.

The handle's knob runs on three bearings instead of two, just like the spool does (shown earlier). This is as ridiculous as it gets. Okuma obviously wanted so bad to have the largest number of bearings in a spinning reel for whatever advertisement value that is supposed to have, so they just inserted bearings everywhere redundantly and to the point of absurdity. The handle doesn't benefit anything from having three bearings instead of two, and the same goes for the triple bearing spool. No mechanical advantage whatsoever and it only increases the number of parts and complicates the reel needlessly with the extra washers and bearing spacers. My issues with the handle doesn't end there; the so called "Egro Grip" is nothing but an annoyingly tiny and hard handle grip that's a pain to use especially when you are reeling in a fish! Look at this

My finger was left with this painful pinch on my last day of fishing the reel, and it happened mainly because of the annoying "Ergo Grip", but also because the reel has very little pulling power which made even playing or retrieving a 200gr jig without a fish such a struggle. The pulling power of any spinning reel is a function of several variables such as the gear's diameter, its offsetting, bevelling, handle's length, tightness of the reel, spool diameter, etc. Overall the VSystem lacked severely in pulling power compared to other reels with similar gear ratios in this size class.

The bail arm pivots on a ball bearing as well (red arrow). More useless bearings just for the count.

The end piece of the bail also pivots on a ball bearing (red arrow). Makes me wonder why they didn't just put 5 more ball bearings in a little bag then glued the bag into a corner inside the gearbox so it would be a 20 ball bearings reel! There are several synthetic washers to smooth up the opening motion, some of which are not needed. I ditched one of them (blue arrow) because it was not worth the effort to align it correctly with the screw. Before we move on from the rotor, the "RES II Rotor Equalizing System" is a rotor that's balanced by mass distribution instead of the prehistoric piece of lead you see stuck somewhere on the rotor in older spinning reels, so it's nothing new or evolutionary. I like how they call it "RES II", as if there was an "RES I" that evolved into this breakthrough

Line roller, pretty basic and runs on two bearings. The "EFR II Even Flow Roller System" is described by Okuma as "This roller helps reduce line twists by freely rolling over the line roller without friction. Without this system, line will naturally twist when drag is pulled". Well, all this mumbo jumbo tells us is that the roller actually rolls (you don't say!), and that last bit about line twisting is first class rubbish. The line on a spinning reel will twist when pulled against the drag even if it rolled on miniature naked mermaids winking at you lustily with every spin. And to finish with the list of supposed technologies in the reel, the "EEB Extreme Element Bearings" is also a fancy name for nothing special. The reel has a few high chromium bearings for corrosion resistance, but most of the bearings are of lower quality. I did not need to test the bearings on the Labmaster for that. Just hold the rotor of your VSystem that has been used moderately and pull/push it in and out and see the amount of play it has developed. That's the dodgy main bearing of the pinion. Not going to affect the reel's function in any perceivable way, but just goes to show that when you buy a cheap reel that comes with an extra spool and still has a million bearings, you should expect that they haven't spent much on those bearings.

The bail arms is metal, but the screw of the line roller is tightened against a shiny plastic back cover so expect to see plastic shavings coming out when you screw/unscrew it.

The bail mechanism, and it's not trouble free either. When you open the bail of the V80A you will feel only a very light spring resistance for the first 5 millimetres or so of the opening stroke, then after those 5 millimetres you'll feel the proper stronger resistance you'd expect all the way to the full opening. This happens because for the first few millimetres of the opening stroke the bail spring does not compress as it should, but rather bends sideways along the red line I drew in the above photo, producing only slight resistance, then after those few first millimetres it starts to compress and produce the correct spring resistance. That does two things: When you close the bail it won't slam firmly still, but rather will bounce into a quick fluttering movement within that area where there isn't enough spring pressure, and also if you're dropping your braid vertically in deep water the line might not slide to the roller when you close the bail because the resistance of the line keeps the bail partially opened for those first few millimetres because of the lack of proper spring pressure to fully close that final bit.

The spool lip got dinged pretty easily. I didn't realise it the moment it happened, but from memory the only time the reel received a hit was when a small Wahoo went right below the boat and I momentarily lost control and the reel hit a metal insert in the gunnel with not much force. I guess that's something we have to accept in reels that don't have those hard stainless steel titanium nitrated lips.

Don't let the number of issues I found turn you off the reel. I always mention every problem I find in a reel because someone involved might read and do something to address the issues. Also me going after the list of imaginary technologies doesn't mean that I hated the reel. I'm just fed up with that whole trend of fancy names for insignificant or completely made up features confusing people most of the time. I don't care if you name it "Hydro Block" or "XShip" or "Twist Buster" or "Versa Drag" or whatever. I want to hear more actual information and less catchy nonsense names. Period. Now to evaluate the V-System in real life practical terms, the three things that make or break a reel are drag, anti-reverse, and gears, and since all three are alright in this Okuma, it should still be a contender if the advantages outweighs the disadvantages in someone's book. On the plus side it's a very smooth reel (lack of roughness and mechanical noise), cheap, comes with a spare spool, quite solid for its class, and it's from a mainstream company that would provide support if needed. The negatives would be the small handle grip, the bail spring glitch, the complexity of changing the winding side, and the low pulling power. The VSystem is by no means the alternative to 6000-8000 Stella or 4000-5000 Saltiga many wish it was, but nevertheless I wouldn't dismiss it as a viable option for lighter inshore applications if you need its pluses and can live with its negatives.

This concludes the first half of my answer to the "V-System or Cabo" question, and in the near future I'll be giving the Cabo a similar full evaluation. I hope you enjoyed the read and stay tuned because in the next 14 days I will be posting a review that you'd want to read before buying a Stella, a Saltiga, a Torque, or a TwinSpin.

Cheers

Was this a good read? Please click here

Alan Hawk

November, 14th, 2012

|