Abu Garcia Soron / Cardinal 807i : The Review

Hello All,

Sorry for the delays in posting this review. It was due 3 weeks ago, but I just wanted to put more use on it to give you a full image. There you go, and hope you find it a good read.

I should start by pointing out something: The actual reel I have here is from the Cardinal 800i series, the 807i. To the best of my knowledge the Cardinal 800i series was renamed to Soron for some reason. Most probably to differentiate it from the Cardinal 800 series (without the 'i'), which are black reels without the rubber rings on the spool and are slightly different internally to 800i/Soron reels.

Naturally for a renamed series, the 800i are gone from Abu site. Someone mentioned that Fisherman's Factory was closing them out for $69 instead of the regular price of $150, so I went there and got it for that amount. My evaluation of its value for money though will be based on the original $150 as this is the price of the reel in its new name, Soron STX 70 (the size equivalent to the 807i reviewed here).

The reel is a medium sized full metal saltwater reel. The body, side cover, rotor, and bail arm are made of a sturdy aluminium alloy. I personally like the colour scheme in that blue finish, silver handle and guards, and golden/silver spool.

Guards (red arrows) protect the metal of the reel where it's most likely to be hit and scrubbed. Those guards are made of plastic so they could be replaced cheaply.

Front view. The drag knob is not the easiest to grip, especially if you have big fingers. The drag is capable of 21.2# of maximum pressure. I don't know what the advertised pressure is, but I measured mine to that figure.

The foot has a simple "Cardinal". It had a small "Made in China" sticker as well but I removed it as it's a sad reminder that no Abu spinners are made in Sweden anymore.

The reel comes with a slightly deeper aluminium spare spool, an extremely crappy reel bag, instructions, warranty, and a promotion card for line brands owned by Pure Fishing, the owners of the Abu Garcia brand.

You have probably seen this in the Soron's promotional video on youtube. The shallow spool wih the rubber rings designed specifically for braid. The theory is that to keep superlines from slipping, two circular grooves with a rubber O ring in each were added to the spool. You are supposed to tighten braid around one of the two grooves until it slips under the rubber ring and be retained there. This is totally useless and nothing but a gimmick. A good ol' piece of sticky tape always does the trick for me when I do not want (or can't) use mono backing. Still, this feature is a part of a theme you will spot in other features of the reel: Refining touches not expected to be found on a reel costing the $69 I paid for it or even the $150 that a Soron costs.

One of those touches is seen on the handle

A single piece chunk of metal with no joints, that feels (and is) very solid indeed. Quite heavy, but I am willing to take the extra weight for the positive and assuring feeling it gives. There is only one other spinner I'm aware of that has a one piece handle..

Daiwa's Saltiga-Z that is. The two reels are in no way in the same league, but it's interesting to see how innovative features trickle down from high end products to affordable reels in a few years. A good example for this is the corrosion resistant ball bearings (CRB) that was a groundbreaking feature of the Shimano Stella back in 2001, but now I've seen them in reels costing as low as $60. Same goes for digitally controlled gear cutting, waterproof drags, titanium nitrated spool lips, etc. All were high end features one day, then they moved down the chain to affordable spinning reels later. This one piece handle is exclusive to the 807i & 806i (Soron STX70 & 60) reels. Smaller reels have a different handle design with a joint.

One big problem with the handle though

The knob is permanently bolted and can not be removed to service the two small ball bearings inside it. The knob on my reel is a little wiggly but I could not take it off to fix because of that permanent bolt. Does not affect the reel's performance though.

Another good bit in the reel is the effective sealing of the drag

Seen above are the top drag seal mounted on the drag knob (1), the lower drag seal mounted on the dual bearing unit (2), the removable bearing unit itself (3), and the two quality bearings the spool runs on (4). I've been inside nearly every spinning reel that has a ball bearings mounted spool, and those bearing systems were either very complicated and costly, or did not work. The Soron's system on the other hand is quite simple in design and works great. Can see this one being copied by others in the future (unless it was patented).

Having a closer look

Right below the bearing unit there is a small seal on the shaft (red arrow) that keeps water from getting to the drag from underneath the spool. The seal rests in a recess machined into the back of the unit. Very impressive considering what the reel costs.

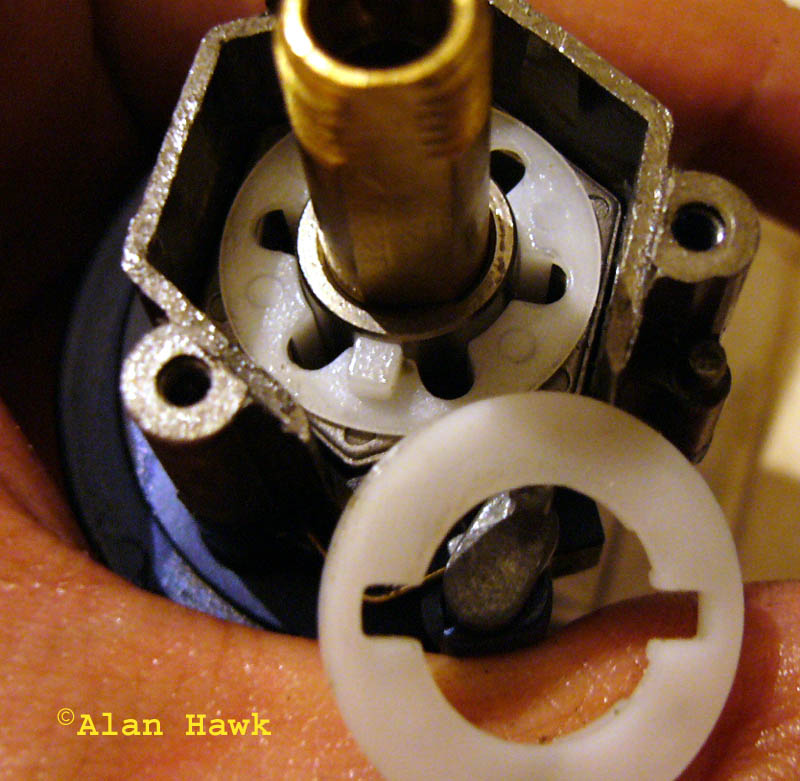

But how to keep this unit that bears the bearings and the lower drag seal from revolving with the spool due to the friction between the seal and spool?

Answer: that shaft seal is keyed to the main shaft, keeping the bearing unit static as the spool gives line to the fish. The drag knob itself is also keyed to the shaft to keep it from rotating and changing drag setting due to the friction between the knob's seal and the spool.

The bearings on the unit

These are quality bearings with laser etching on the outer races. All the 10 ball bearings in this reel are high chromium corrosion resistant type that can withstand saltwater environment, especially if the owner was too lazy to rinse the reel at the end of the day. This neat unit is held together by snap rings on both ends.

The line roller

A tiny ball bearing inside, also kept in place by a miniature snap ring. Had there been no retainer in here it would have worked just fine. But the attention to such detail and the extra machining required to create a recess for that tiny ring are just astonishing considering the price.

The bail arm

Pointed by the red arrow is the lever connecting the bail arm to the spring. The story goes like this: The rotor's arms are angled to create a nice visual style for the reel. That angulation means that the bail spring could not be placed in the regular position straight below the bail arm, therefore and not to sacrifice style for function, they used this connecting lever to reach and compress the spring in its unusual position.

The rotor's arm

Normally you only need to remove that screw (red arrow in photo above) in order to take off the spring cover and fully disassemble the bail. But...

...that first screw is only for the Abu Garcia logo, and underneath there is a second screw (red arrow) for the spring cover. Good amount of work on a reel of this price.

Taking off the rear guard exposes an opening in the gear box

I strongly believe that this opening is meant to be a service port through which owner could spray the internal mechanism with grease for a quick servicing without taking it apart, and also useful to drain water out and lube if the reel got accidentally submerged in saltwater.

The one way anti-reverse clutch unit and the on/off switch. Nothing special on the outside.

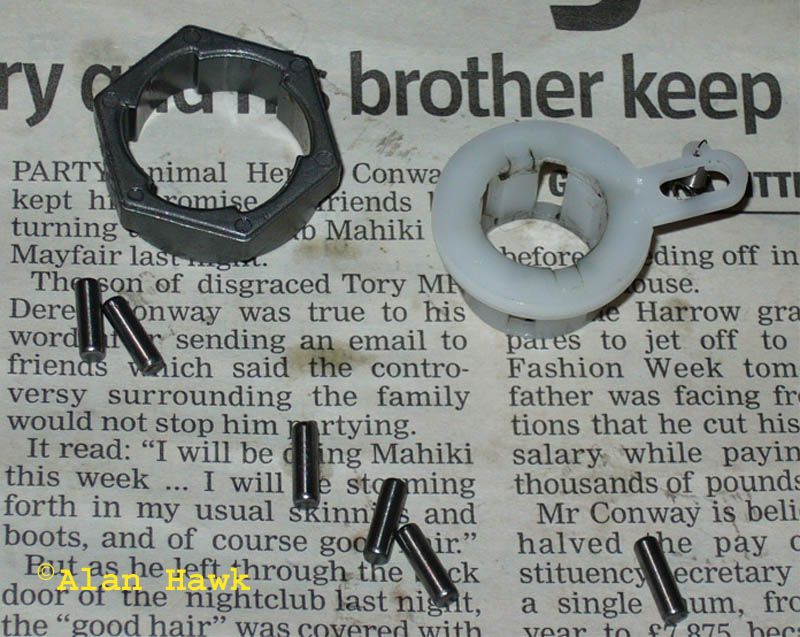

But look at this

The cage is not the common one piece type that is a pain to install while trying to keep the cylinders from falling. Here it's a two part cage with a removable top exposing the cylinders' housings. This way you can put the cage in place, then remove the top and drop the cylinders easily one after another before replacing the top.

The clutch components

The brake cylinders are longer than usual providing a more secure lock of the rotor, and it was interesting to see that the cage had no plastic V springs in the vertical slots: Spring-type one way clutches have no back play, while no-spring type have a slight back play. It would be a no brainer then to make all reels with spring type clutches, but it's not that simple. In most spring type clutches the springs are plastic V shaped extensions moulded into the cage, which means that each time the rotor spins, the plastic springs are compressed, using their own elasticity to spring back when the rotor stops. Eventually that elasticity will decrease and the clutch will begin to slip. So to sum it up, spring type clutches are play free, but no-spring type ones has a longer service life. An exception to this rule is Shimano's Super Stopper which uses stainless steel coil springs for each cylinder, meaning that it provides a no-play stoppage while having a very long service life.

Side cover removed

The main gear's bearings are the same corrosion resistant type. Obviously Abu did not try to cut cost by using cheap bearings.

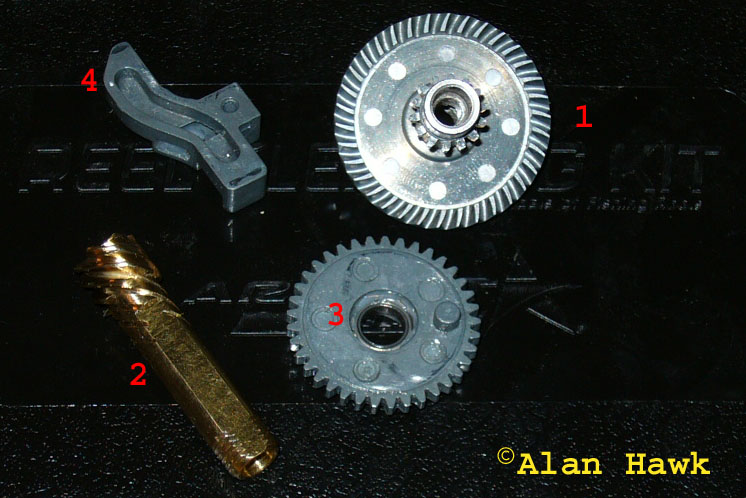

The drivetrain, cleaned of old grease

Seen here is the drive gear (1), the pinion gear (2), the oscillation gear (3), and the traverse cam (4).

The pinion gear is a durable and dependable piece of machined brass. The oscillation gear is problematic though. It has a ball bearing in the centre, which is fine, but ball bearings by nature has radial and axial play, making them unfit to support a gear standalone without causing much play to the gear itself. In better quality reels that have a ball bearing oscillation gear there is a secondary support system to the gear in the form of another gear beneath it or a Teflon washer etc. But unfortunately there is no such support in the Soron, leaving the gear uncomfortably shaky. In low cost reels an old style bushing on a body stud would function better than a ball bearing. With extensive use of the Soron the oscillation gear will be the first part to suffer wear.

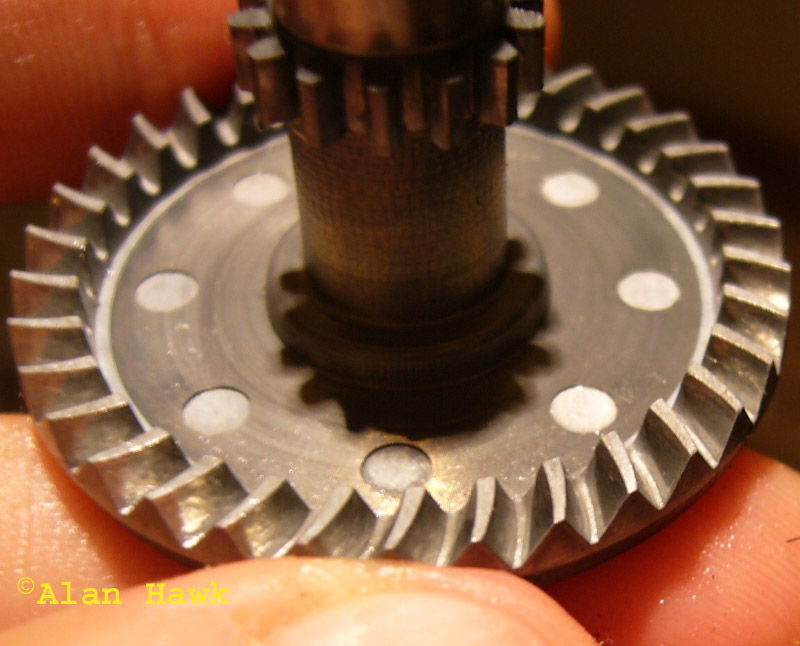

The main gear

The drive gear had me confused for a while. The polished look of the surface and the accuracy of the teeth do not correspond to a typical die-cast part, yet close examination finds no machining marks. The sprue marks around the shaft though leave little doubt that it's made by casting a molten alloy, and that would make it a casting process of higher precision than I'm used to seeing in reels of this price. Anyway, I could tell from my experience that relative to the use I put it through, the gear has a low wear rate. A strong drive gear to complement the pinion, and a combination that produces very smooth winding.

The 'naked' body of the reel

The body feels rugged and the thickness of the finish could be felt by running your finger where the finish meets the non-finished parts beneath the rear guard. The red arrow above points to the housing of one of the 2 rotor bearings.

Here they are, the two bearings the rotor is mounted on (red arrows).

And, I saved the best to the end. The drag

The drag washers are carbon fibre, which is one of the best materials available today for reels' drags. These washers are quite big in diameter relative to the reel's size. This reduces the line capacity a bit, but the resulting smoothness is impressive. The starting inertia is very low, and actually lower than that of a Saltiga 4500 with factory drag washers. Finally, that separator disc (3) is inspired by the old Stella 8000/6000. What it does is that it divides the drag washers into two groups and keeps them separated, while transmitting the pressure to the lower washers group via the rim of that eared metal washer (4). This separation reduces potential stickiness in the drag stack and provides space that allows for better heat dissipation. Those who have been in long fights with big fishes know what heat buildup can do to a drag stack. Still in the above photo, they did not just put a wire spring to keep the drag washers in place as most do. Rather they made a retaining disc with threads on its edge (1), which has a recess in which a rubber seal is installed (2). When this retainer disc is screwed in, it both keeps the drag stack in place and makes it waterproof.

I was asked by a member to test the reel at 18# of drag pressure to see if the main shaft would bend. I used this dumbbell from my home gym, weighing 9 kilos (19.8#)

I put the reel on a broken rod, and dead lifted the dumbbell vertically with the spool fully extended (most vulnerable position for the shaft), and held it for 5 seconds. I then checked the main shaft and it was alright. I wanted to add more weight and see how far it can go, but I refrained because it was not designed to be fished at drag settings higher than this. This is plenty of drag pressure to handle, and the shaft seemed to take it very well.

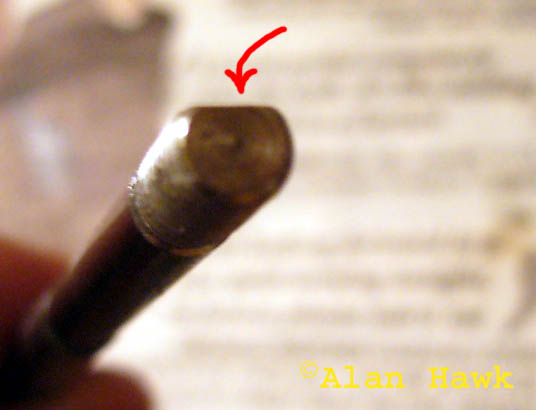

The main shaft

The shaft's strength comes from the fact that it is cut on one side only (red arrow), not two sides as in other reels.

For members of the "Free reels movement"; no reels were harmed in the making of this review

The photo is actually of the reel before the disassembly, but those reel rights groups do not know any better

In addition to the drawbacks I mentioned in this review, the anti-reverse was slipping a lot. Here I was alone on a jetty at 1 am throwing and retrieving with no bites, then I finally got one, made a heartily hook set, and bang! I fell on my back severely bruising my elbow in the process, and it happened because the anti-reverse slipped just as I was striking. Later when I opened the reel I found excessive amounts of grease in the clutch, a big no no of course, so I cleaned everything then put some light oil on the clutch's components and there has been no slips since.

I loved the reel, and in my book it has now replaced the Tica Taurus as the best value for money spinning reel available. It's in no way perfect or trouble free, but for the price it is simply brilliant. It is no secret that since the discontinuation of the Suveran Abu only made rubbish spinners, and this reel gives me hope that this could one day be changing.

Hope you enjoyed the read, and stay tuned for the Stella SW 20000 review at the beginning of March when I come back from abusing it in the Seychelles.

Cheers

Was this a good read? Please click here

Alan Hawk

January, 21st, 2009

|