2019 Shimano Stella SW (SWC) : The Review

Oi lads and lasses

I rarely hear from women in my mailbox, and when I do they're often ones looking for a nice gift for their fisherman husband/boyfriend/dad. Most of the time they know little to nothing about fishing, yet some would still mention having heard the name "Stella" uttered with reverence by the fishermen in the family. There certainly isn't a bigger testament to the reputation of a product than being known even by people who have no interest in the subject. In the world of fishing very few names have the prestige of the "Stella" name, despite instances when in my opinion the reels did not live up to expectations. Today we look at the latest incarnation in the saltwater series, the SW-C or the 2019 Stella SW as it's known in Japan. Some sizes of this model were released in 2019 then more sizes were added in 2020, therefore all models belong to the "2019 Stella SW" generation and any reference to them as "2020 Stella" is inaccurate marketing in my view.

For the first time in a very long time the new Stella SW did not change its colour scheme. Still black/golden, although the black of the 2019 reel is very subtly darker and denser than the black of the 2013 model.

I first broke the news and posted pictures on December 5th, roughly six weeks before any official word, and since the new reel had the same colour scheme as the 2013 model, some assumed that I got confused and that there wasn't really a new one. Even some long time readers who got in touch still appeared suspicious despite my reassurance that it was real. Fun times!

Keeping the colour scheme makes sense to me, because that black and gold combination is very pleasing to the eyes. What didn't make sense was the arbitrary rule that colour must completely change with every new generation even if the previous one felt just right. I hope they won't change it in future editions and instead embrace it as the official SW colour scheme.

Looking past the colours though reveals significantly updated visuals, such as new body sculpting which produces a more compact gearbox, and the reshaping of the bump that houses the secondary set of oscillation gearing.

Completely new rotor design. Sleeker looking, the angled rotor arm bases are positively aggressive, but that plastic silver top is visually intrusive and I think it would've looked less so had it been finished in black like the rotor. The porting in that silver top looks too futuristic and certainly veers away from the relatively reserved look the Stellas are usually known for.

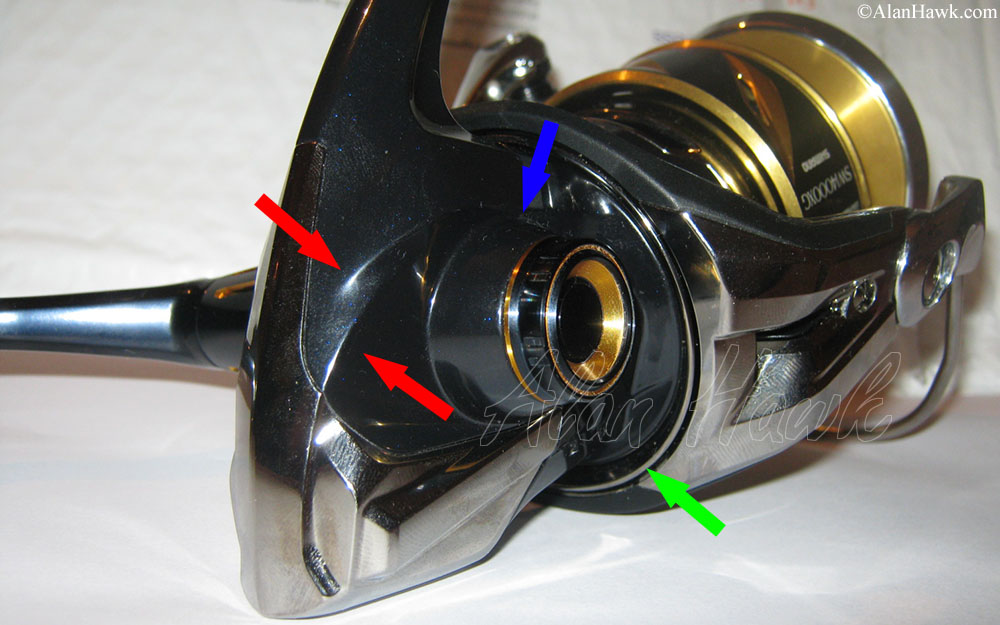

To my absolute elation the design of the handle's hood and joint is a complete departure from the abomination that was in the 2013 SW model. They also did away with the trashy looking golden handles that came with some high speed models in the previous two generations, and now all models come with a lovely black handle. To differentiate between high speed and low speed models in the new SWC, the HG and XG versions have subtle golden highlights in the slits of the handle's hood and the little cap as seen in the above photo of my 14000XG (red arrows). In PG models these highlights are silver instead of golden (inset).

The drag knob now matches the colour of the body, and the black plastic spool cap no longer has any text. That whole "X Rigid Drag blah blah" printed on the spool cap of the previous model looked corny and made it look more like a promotional pamphlet than an actual reel.

That plastic spool cap is now split into two levels, giving it a very appealing appearance compared to the bulky single level cap of the previous Stella SW. That's a last minute decision though, as I've seen late prototypes of this 2019 model that had the exact spool cap of the 2013 reel. Whoever is responsible for this late change deserves a fully paid Hawaiian trip, while those who did the aesthetics of the previous Stella SW need to be sent to clear landmines in Fallujah for a week to be extended by another week if they still have all their limbs.

I mentioned aggressiveness earlier, but no other part looks remotely as aggressive as these new spool cuts. Sure, the cuts in the previous generation were aggressive in the sense of them saying "show me that damn fish and let's get some action", but the new cuts are pretty much screaming "yank those bloody fish in, shove me down their throats until they choke, then take me home where I'll beat you up and kidnap your dog". As seen in the photo, these are not simple flat cuts with chamfered edges as in previous Stellas, rather they are three-dimensional ones with varying depths and internal angles. In addition to looking mean, these 3D cuts reduce weight because more metal is removed.

Correspondingly, the text on the spool's skirt is now vertical instead of the traditional horizontal orientation in order to provide more space for the weight-reducing cuts. Seeing vertical text on this saltwater reel still amuses me, because for a long time vertical spool text has been a distinct feature of freshwater Stellas as can be seen on the 2010 (FE), 2014 (FI), and 2018 (FJ) models. What's not so amusing though is the "USA/PowerPro" thing. PowerPro is a brand owned by Shimano, so this comes across as a vulgar form of advertisement that belongs in a printed catalogue or on a website, not on the body of their flagship reel. Please don't tell me it's only done to provide a reference for braid's diameter, because typing the actual diameter would've taken much less space.

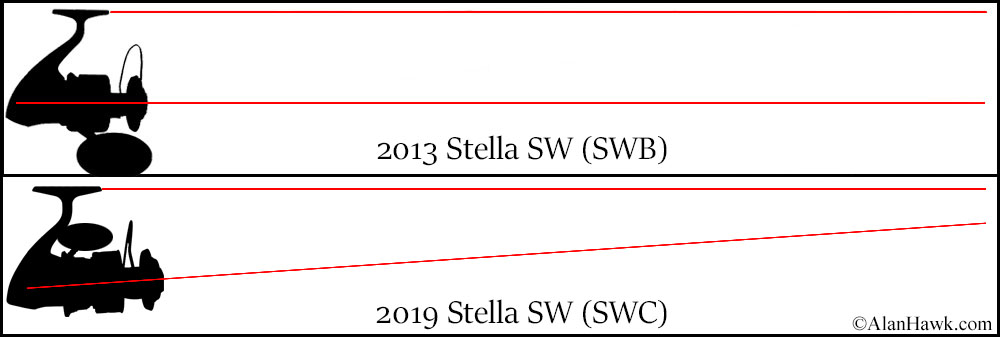

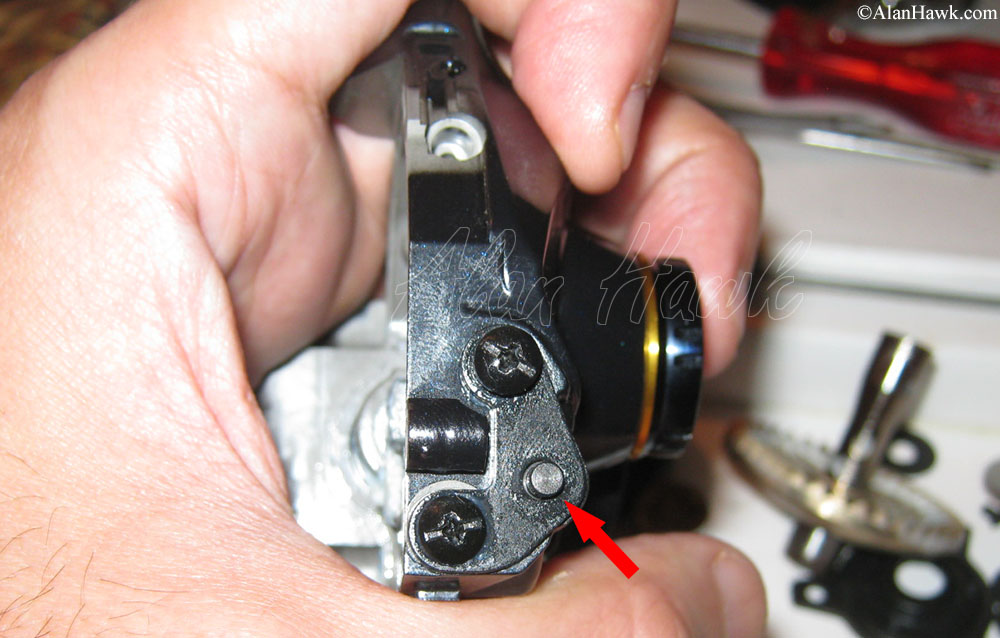

Not all weight-reduction measures were harmless though. The bail arm was reshaped to have a slimmer base, but removing metal from that area left the internal bushing exposed and protruding, creating this terrible eyesore. Not only is it ugly, but I personally feel that a lot of laziness and cheapness were involved here. Instead of creating new parts for the new SWC, they simply took the bushing and screw straight from the previous SWB generation and threw it in what's supposed to be their new flagship. In the previous reel these two parts were fully buried inside the thicker bail arm base, but in the new slimmer base they protrude. Of course no one in their right mind would suggest that the artistic designer of the new SWC drew the flowing lines of the reel then intentionally interrupted them with an upward sticking bushing.

Further evidence to my suggestion about laziness and stinginess...

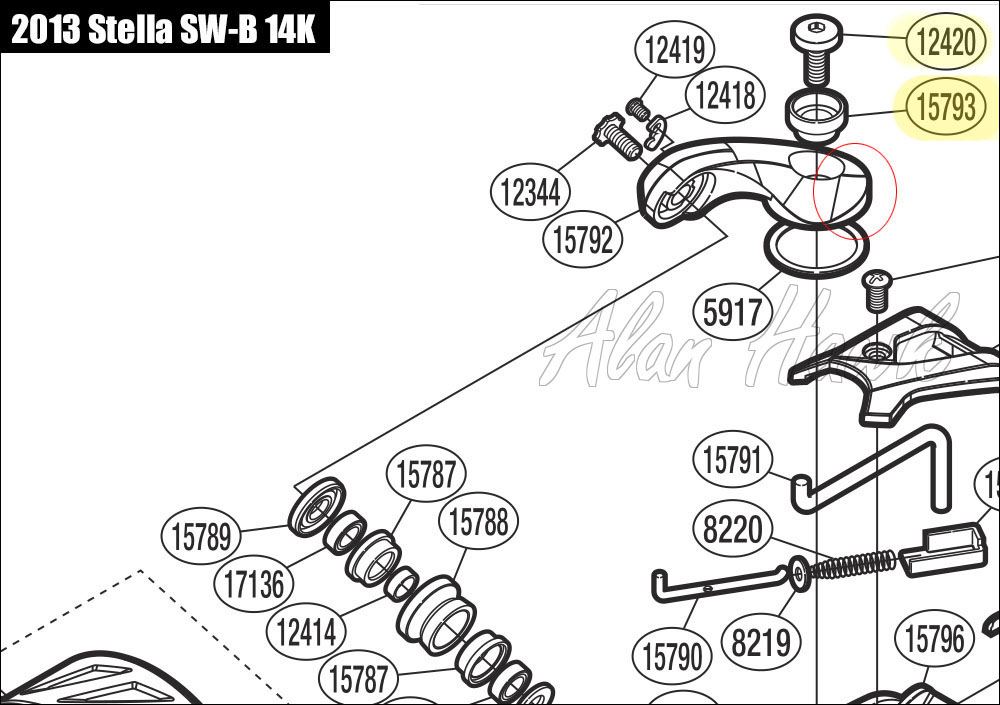

These are the schematics of the 2013 SWB with the long format unique part numbers. Check the numbers for the bushing & screw that go into the thick base of the bal arm (red circle)...

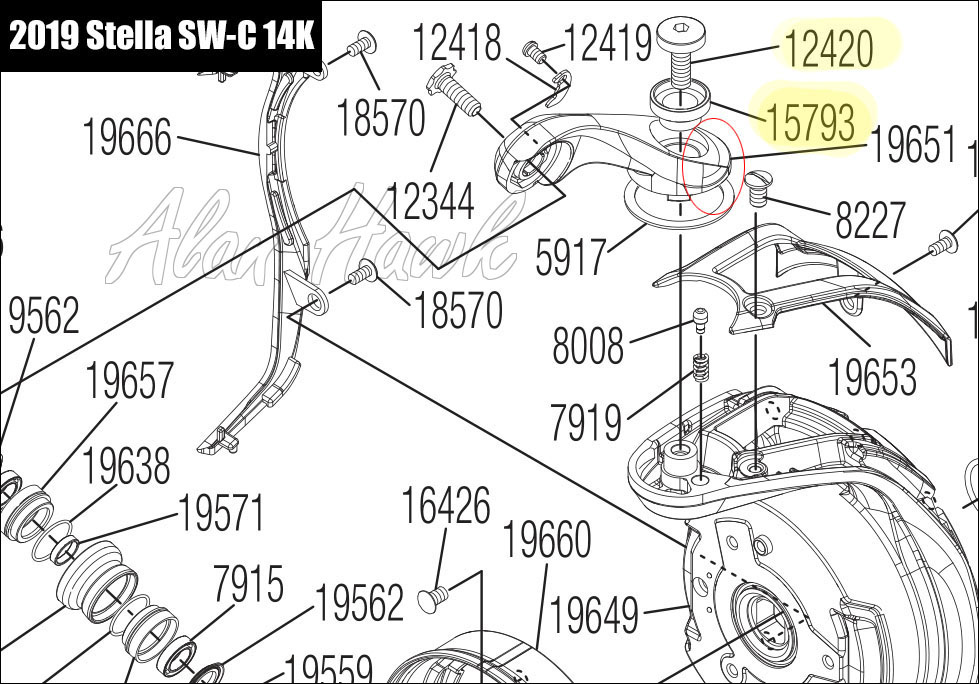

And compare them to the numbers for the bushing & screw that go into the thinner bail arm base (red circle) of the new 2019 SWC. Note that this can't be fixed simply by shaving down the bushing because it barely covers the head of the screw, and no one wants the metal head of the screw to be protruding instead. This failure is pronounced in the mid-sized reels released in 2019, but less so in sizes added in 2020. I imagine that someone saw the initial edition of this review last year and tried their best to mitigate the issue in the 2020 released sizes.

This protruding bushing does not interfere with the reel's operation at all, and the bushing is smooth enough for even frayed rough braid to slip on it without issues. But the real question lingers; is this something that should be present in a reel series whose MSRP is as high as $1200? Let me shut down all the excuses because I've heard them all since I posted the initial version of this review;

- Imbecile: your reel has a loose screw, other reels are fine".

- Response: no, saw it first hand on a number of production reels, and even collected tens of photos from auction sites and videos of people unboxing their mid-sized 2019 Stellas all showing this thing sticking out, so independently verifiable proof is abundant and ready if needed.

- Imbecile: it's not a design fault, just a mix up of parts at the factory when assembling early batches".

- Response: and that mix up made it into the official schematics as well?

- Imbecile: it's not a fault, the bushing is supposed to protrude for practical reasons".

- Response: then why was it partially addressed in sizes released later in 2020? And more importantly, if the protrusion of the bushing is the correct design, then did the previous 2013 model have the wrong design, since its bushing was buried and didn't protrude?

- Imbecile: it's a big company, lots of money, smart engineers, they know better than you do".

- Response: this is called the "appeal to authority" fallacy, and I personally call it "releasing your inner woman". That's when you're presented with factual, reasoned, and well evidenced issues, but because you lack the mental capacity to argue back you just vaguely appeal to some higher authority that appears to have superior knowledge in your inferior mind. It's basically like when a woman is so overwhelmed in a situation so she calls on her man to deal with it, hence my moniker of "releasing your inner woman". Next time you think of responding to an issue by saying "their engineers are so smart", you might as well add "and they are so handsome, so protective, so dominant in bed, and always there for my emotional needs", because that would be you elevated estrogen talking. Reduce soy intake in your diet and man up.

- Imbecile: who cares about your nitpicking, the reel works, look at all the big fish pictures.

- Response: only valid if I had claimed that the issue prevents the reel from catching big fish, which is not something I said here. Keep saying "who cares" and eventually anglers will say "we care" then go spend their thousand dollars somewhere else.

Moving on

Do you see this? It's a screw hole that was drilled through, oddly coming out in the middle of an angled spot in the rotor arm. Yes, an angle of all places. My problem is not that the screw hole is drilled all the way through, that's normal and even desirable, and when done correctly the hole ends in a flat or curved surface. Ending it in an angle though leaves you with this...

This is a closeup of the hole in my SWC. Since it ends in an angled area, the side wall of the hole was drilled out leaving us with partially exposed threading and the sharp edges of the interrupted threads.

A better look at those sharp edges, and the curved arrows point to where thin metal at the tips was bent inwards and outwards as the drilling bit went in and out, and later during finish.

To rub salt in the wound, the paint gathers unevenly in clumps around those mangled edges. This phenomenon is present in mid size reels 8000/10000/140000, but the smaller and larger sizes were spared because the location of the screw is different. This is aesthetic criminality, and in my opinion an indication of more laziness and an apparent lack of interest unfitting for what's supposed to be their crown jewel product. I am literally speechless. Look again at the photos, and tell me honestly whether you think I am overreacting or rightfully disappointed in what I'm seeing in a reel that has a 4 figure price tag.

Ugly stuff aside, this picture captures the much improved contours of the SWC. The red arrows point where the body shaping takes the beautiful form of different surfaces coming close to merging but not exactly lining up, reminiscent of seawater swirls around a rock. The blue arrow points the gear shaft housing emerging assertively from a depression in the compact body. And the green arrow points to where the flange of the body sinks inside the rotor, with a newly added silver flange shield extending backwards as a first hurdle against water intrusion.

Overall, looks-wise the 19' Stella SW has some unsightly features, but it certainly is a much better looking reel than the previous 13' Stella SW. The move towards more futuristic visuals though risks making the reel look generic, because once it departs from its trademark restrained styling it would be stranded in the middle of nowhere having neither maintained its old reserved self nor went all the way into the realm of ultra futuristic aesthetics. I now sound like one of those fashion gurus at the Academy Awards arrivals, so I better move on from looks to the real stuff.

Made in Japan, a country that has become to fishing tackle what Switzerland is to watches.

Since the colour of the Stella SW's box usually matches the reel's colour scheme, the box is black just like the previous model. It comes with a bottle of oil, a spool band, a bag of spool shims, the extra handle axle needed to change the winding side, schematics, a general spinning reels' manual, a Stella SW dedicated manual, a pamphlet with additional Stella SW information, warranty papers that differ based on your location, and the reel's bag.

The bag is double pocketed to keep the handle separate from the body, and both the materials and finish are of high quality.

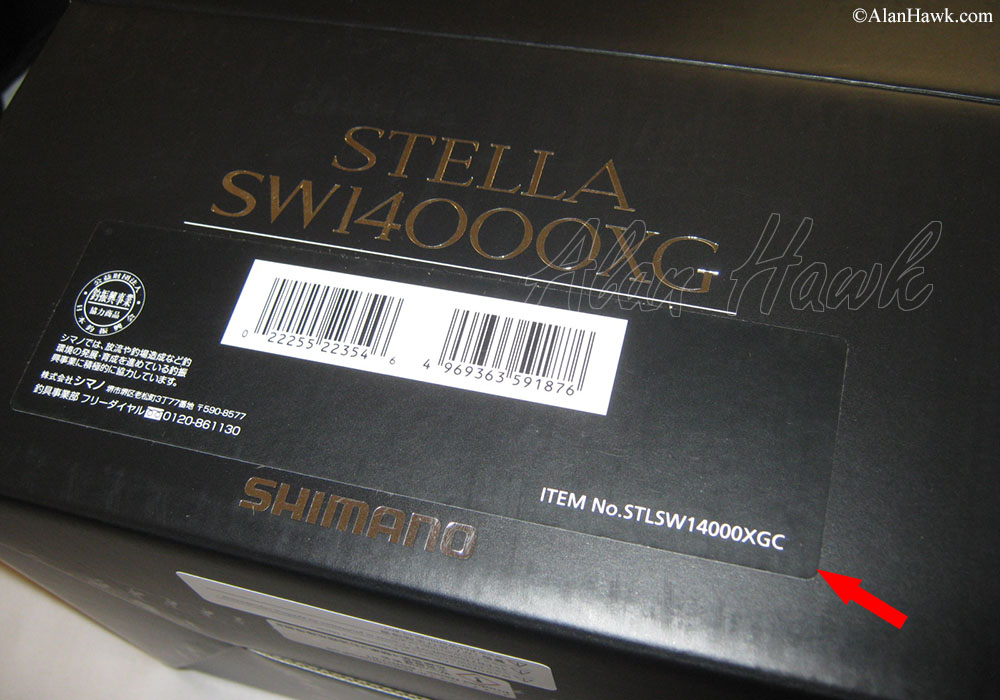

As was the case with the 13' Stella, boxes of reels exported to overseas markets have stickers bearing region-specific product codes and information. Using stickers instead of printing boxes specifically for different regions is a way of keeping costs down.

The Stella SW is the saltwater version of the Stella line. The number of models changes with each generation according to what Shimano believes the market demands, so for example the 2013 generation had 14 models, the 2008 one had 13, the 2001 edition had 10 models, etc. Of course that's for the Japanese market, while overseas markets often don't get all models based on local needs. The price of the new Stella did not change from the last generation in Japan, but internationally prices vary based on several localised variables including but not limited to currency exchange rates and value added tax (VAT). For the American market the prices dropped by roughly 15%, and I'm using American prices as a guide since there is generally no added tax in the USA unlike some other places where up to 20% tax may be added.

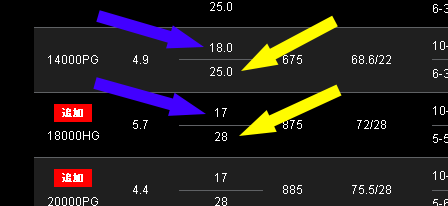

The reels aren't usually released all at once, rather they get spread over a few months, and in rare instances with very late arrivals such as the 13' SWB 6000XG which was released almost 4 years after that generation's debut. For the SWC, medium sizes 8000/10000/14000 went on sale in 2019, then in 2020 they were joined by the smaller 4000/5000/6000 family as well as the bigger 18000/20000/30000 group. At this time there are a total of 15 models in different size/ratio combinations in the Japanese market.

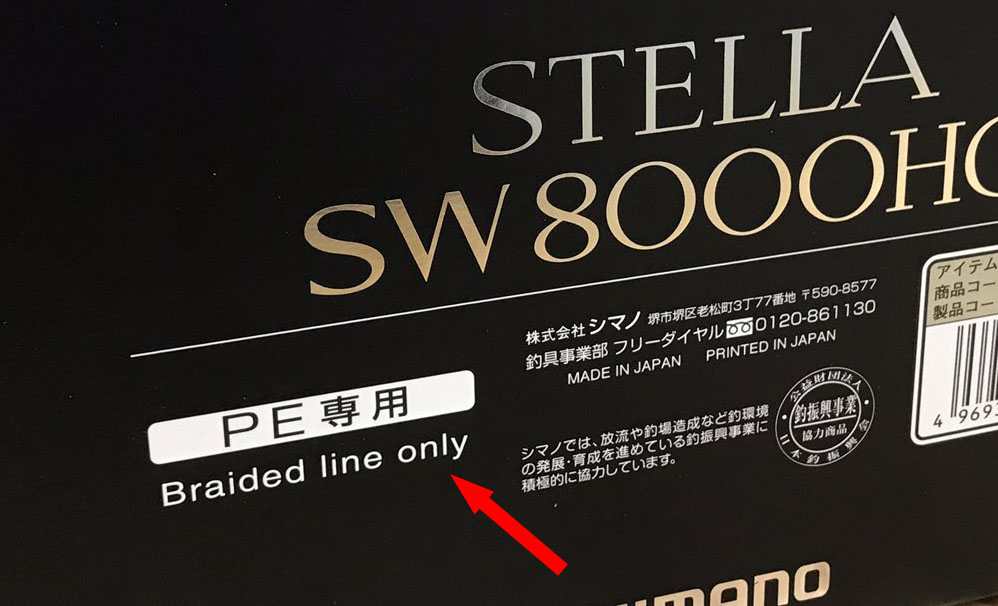

Size 8000 of the new Stella is designated for use with braid only. The reason behind it requires a bit of background; in the previous SWB sizes 8000, 10000, and 14000 shared the same rotor, the same distance of spool oscillation up and down, but had different spool diameters of 61, 66, and 68.6 millimetre respectively. Since the spool diameter of the 8000 is relatively smaller than its sisters, the 2019 SWC 8000 received its dedicated smaller rotor, which both reduces weight and makes it look more proportionate. The length of spool oscillation stroke though remains the same as the 10000/14000, therefore at the extreme ends of spool oscillation the line on the 8000 spool would be at acute angles with the line roller, possibly causing mono to slip on the spool resulting in erratic drag performance or casting issues. Anyway, having done some experimenting around I'd say you'll be fine with a mono top shot as long as it's not very thick. A ballpark figure would be around 0.40 mm (0.015 inch) thick at most, but that remains my personal estimate and exceeding it a little might still work for you.

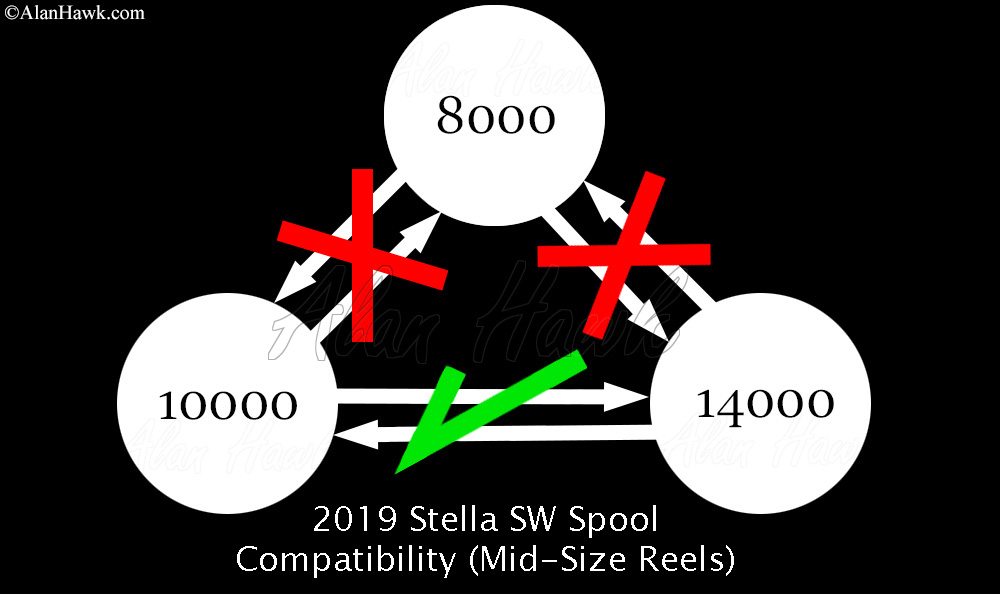

Another consequence of the 8000 size having its own dedicated rotor is that spools are no longer interchangeable between the 2019 Stella SW 8000 on one side, and the 2019 Stella SW 10000/14000 on the other side. Spools remain interchangeable between the 10000 and 14000 sizes. I created this simple diagram to help you quickly figure out the spool compatibility in this mid-sized group.

In small reels, spool interchangeability remains the same. 4000 size isn't interchangeable with any other SWC reel, while spools are interchangeable between 5000 and 6000 sizes.

In full-size reels, spools are interchangeable between 18000 and 20000 SWC reels.

There is no spool interchangeability between the Mammoth sized 30000 and any other SWC reel.

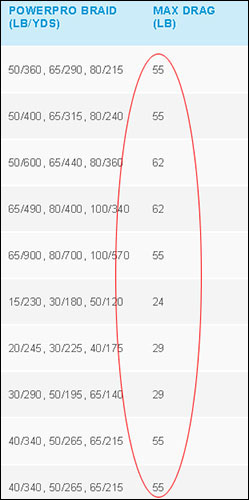

I believe that the claimed maximum drag outputs are some of the worst cases of drag power exaggeration that I've seen. For example the 14000 is supposed to output 25kg (55lbs), but on a filled spool -which is how one actually fishes them- I only got 17.4kg (~38lbs). I tried again on a virtually empty spool to see if that's where the claimed figure comes from and I got 19.8kg (~44lbs). The 20000 is supposed to produce 28KG (62lbs), but the best I could get on a filled spool was 18.7kg (~41lbs) and 22kg (48.5lbs) when almost empty. I therefore believe that even in a completely useless state without much line the actual maximum drag is inflated by roughly 27%, and in a usable state the drag is inflated by 46% on average. For these tests the drag knobs were maxed out using a reasonable amount of force that an average male would produce. More drag could be generated if dangerous overtightening is used, but that is not how it's supposed to be done, plus even doing that would not output the claimed maximums in my opinion. I personally believe that these numbers are pure fiction.

The new Stella SW has a full metal frame made of cast aluminium alloy, and it lost a little bit of weight compared to the previous model. The advertised weights are generally accurate within acceptably small margins.

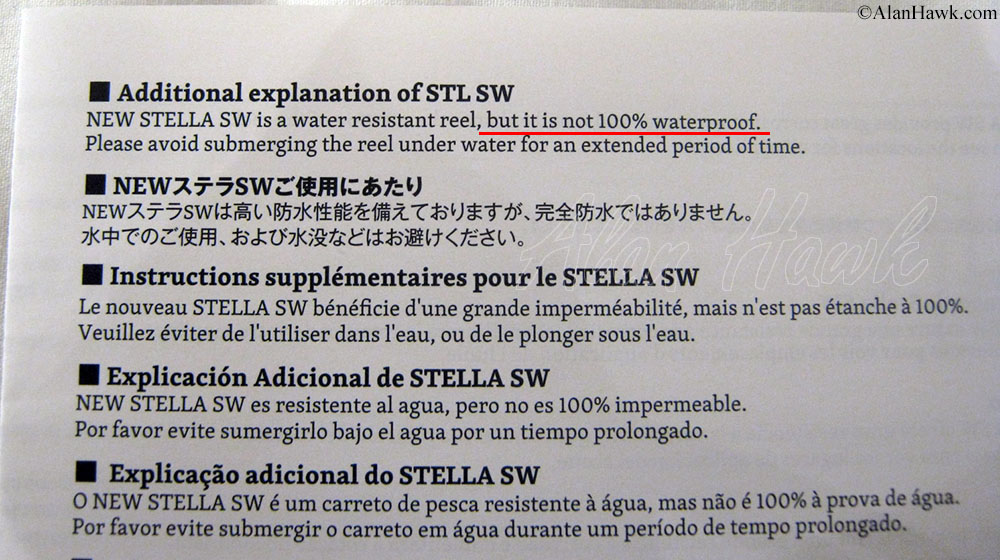

Shimano is all over the place when it comes to the SWC's water resistance. One of the brochures that come in the reel's box says this

"It is not 100% waterproof"

But the official website says that it's "waterproof". So which one is it? Well, you can figure it out yourself using the following experiment. Follow the instructions carefully for the most accurate results.

You'll need:

1) Some tap water.

2) Finely ground coffee.

3) A standard plastic credit card, not one of those fancy metal credit cards.

Method:

- Boil the water.

- Put the coffee in the hot water.

- Drink it.

- Go online and use the credit card to order a Ouija board.

- Use it to make contact with the spirit of a 12th century sorcerer and ask him whether the SWC is waterproof or not since Shimano apparently can't decide!

Neat, ain't it?

Anyway, I found the SWC to be waterproof, and on my own sealing spectrum it sits higher than the previous generation, slightly below the Makaira, and considerably below the Van Staal X series. I'd say you can submerge it for as long as you want at depths no more than a human's height, a quick spin underwater will not do damage, but operating it underwater for any length of time could cause leaks. I'm definitely happy with the new Stella's sealing. Remember though that you must always adhere to whatever the manufacturer says because they're the ones who will decide whether to accept or refuse your warranty claim if something goes wrong. My take is something that I write for informational purposes and it should have no bearing on your adherence to manufacturers' instructions.

Before we move on, let me quickly address the "IPX ratings" thing, which has been increasingly appearing in promotional material of reels. To me it's a naive marketing tool with principles that can't be applied with any uniformity to objects of complex structures such as reels. To realistically evaluate a reel's water resistance one needs to have full understanding of its build, possible water entry points, the type of protection at each, and the difference in sealing performance between operational and non-operational phases at each of these points. This can't possibly be substituted with a nozzle spitting water at a reel from a particular angle, and it's beyond idiotic to believe that it could. Moving on.

If you have extensive experience with older Stella SW reels, you'd immediately realise that the 19' model feels different to previous generations, in a good way. One of the first things you'd notice is the dramatic reduction in handle play, colloquially known as "backlash". The most conspicuous difference though is the unmistakable improvement in smoothness. Once again "smoothness" is the fluid operation and consistent feel with absence of mechanical noise, not to be confused with "free spinning" which is lack of resistance when turning the handle. The 13' Stella SW was already buttery smooth, yet this one managed to become a tad smoother. On the other hand free-spinning remains roughly the same, and of course I've taken different gear ratios in consideration and compared apples to apples. Generally speaking high speed reels feel harder to spin than low gear ratio models.

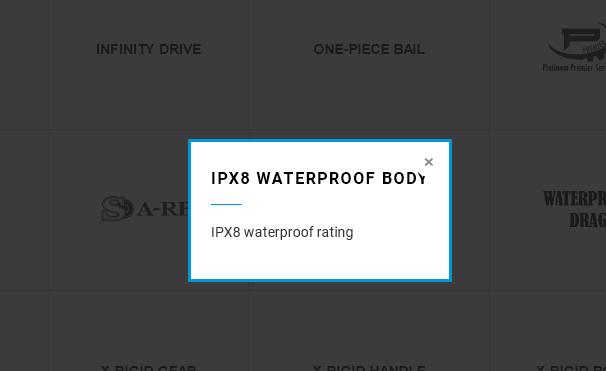

Another major change that's going to make every single one of you happy is the foot angle. After a multi-year adventure with the parallel foot design, Shimano decided that it heard enough of your outcries and switched back to a classic angled foot. The following diagram should explain it to those unfamiliar with the concept

I've always reported on the parallel foot in a cold factual manner without criticism because it wasn't a design fault or something that I considered to be an ill-advised feature. Rather it was something different that had its advantages and disadvantages, and if matched to a rod with rings that meet certain criteria for dimensions and distance from the reel one would minimise the negatives and maximise the positives. Anyway it's gone from the 19' SW which should put this matter to rest, although the optics of it aren't very good. When a major company makes such a monumental change in design only to reverse it on the very next generation, it doesn't exactly inspire confidence or give the impression that they know what they're doing.

Another thing immediately detectable is a silly design flaw; there is a thin synthetic washer beneath the bail arm for smoother operation. Red arrow shows its normal position.

When the bail arm is pressed down though, the washer slips from its position and retreats inside, allowing the bail arm to slam against the rotor without a buffer. It doesn't only happen when pressed by fingers, but when testing the drag with the reel attached to the rod mimicking real life use I could hear the click of the washer slipping, and that washer would then bulge from the other side and the bulge is easily felt when touched.

To further demonstrate how the washer becomes completely dislodged after the initial slippage, I continued to press on the bail arm while opening the bail, and the now-dislodged washer comes out like this.

Another angle.

Furthermore, the following are official Shimano promotional pictures released with the previous 2013 Stella SW reels, showing that washer completely dislodged as well

Zoomed

Another

-

And zoomed.

-

I brought this issue to everyone's attention in a previous blog post (HERE), in which I published a collection of reports I received from several fishermen and some of the better quality videos they sent me demonstrating the flaw in different models. As ridiculous as it is, it remains an insignificant flaw that has no real effect on operation or performance. I hope though that it gets rectified.

The drag knob is aluminium, more metal has been removed around the bar for a slightly deeper and better grip than the 13' model, a black notch in the bar serves as a position indicator, and the entire knob has a mounted seal around its rim.

The knob's pressure disc is machined aluminium, keyed to the shaft, and a replaceable clicker raceway is mounted on it.

This spring-loaded plunger slides across the raceway from the previous photo to produce little clicks as you adjust the drag. I found that after a few months of use, the sound of this internal knob clicker becomes muffled and it's feel becomes less crisp and more mushy when some drag pressure is applied, but once the knob is backed off clicks become normal again.

The main spring, which is the now-familiar wave spring from the previous generation. Wave springs deliver a more linear progression of drag pressure, particularly at higher settings where standard coil springs would've lost most of their elasticity causing accelerated increase in drag pressure.

The stainless nut beneath the spring, whose threads engage those of the main shaft to generate pressure. Overall the drag knob of this reel is reliable, and once you get used to the different feel of the wave spring you'll find it very predictable. It has an operational fault though; while tightening there is a point where something slips inside the knob, so that for about 5 millimetre of movement the knob turns without actually doing anything, then it catches on again. This happens intermittently, particularly when the drag knob is tightened, backed off, then when tightened again that slip happens. It's something that's mostly felt and not really heard, yet I tried my best to capture the tiny "smack" sound it makes when that slippage happens in this video, recorded when the reel was still new right out of the box. Listen carefully, the slip occurs at the end

I excluded all external suspects such as disc slippages within the spool itself, etc., and concluded that it certainly happens inside the knob itself. My best guess is that one of the moving parts inside binds in one direction and stays there held by friction, then during tightening the tension of the spring reaches a certain level that overcomes the friction holding the binding part so it slips then stops at the opposite limit of its clearance. Unless I have a fully transparent knob I can't definitively figure out what binds, so this is as far as I can tell. In the heat of actual fishing one would not notice this unless they were paying attention, so I don't see it as having a perceptible effect on the workings of the drag. I think nonetheless that these flaws have no place in such a costly piece of equipment from which one expects refinement, not just a working reel.

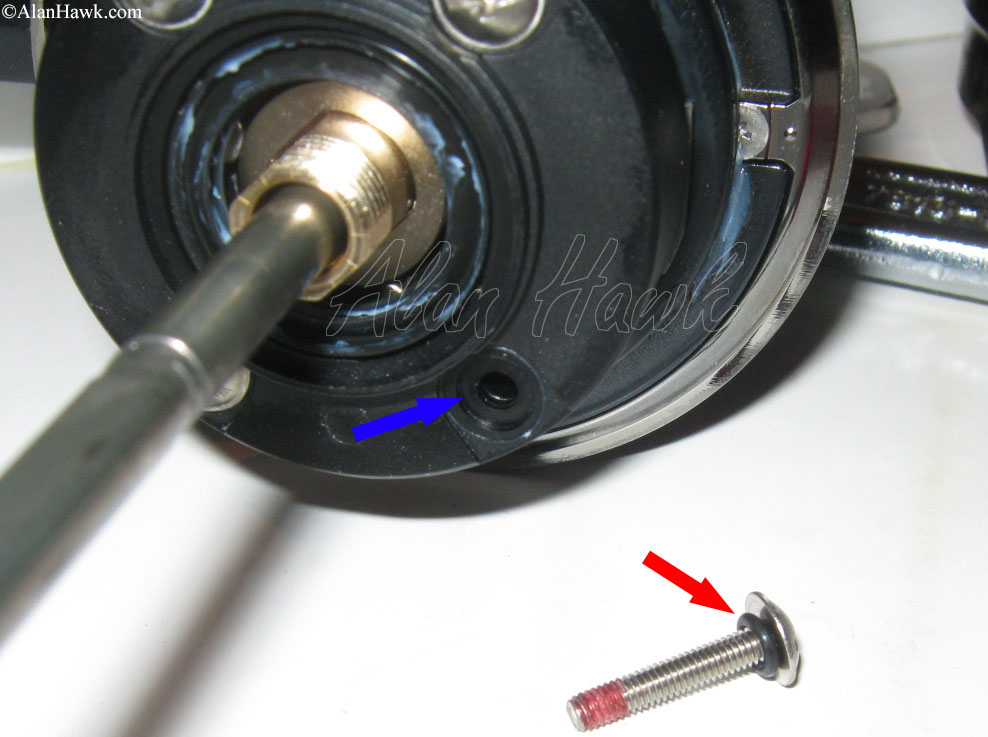

The spool has been completely redesigned both in visible and hidden ways. One of the more subtle changes is a tiny hex screw in the top well (red arrow) which goes through the metal and into the plastic black spool cap (blue arrow).

A closeup of the screw in case you can't see it. Previously the black spool cap was screwed in place with some Loctite to secure it, making it hard to take apart if needed for whatever reason. In the 19' reel though this tiny screw retains the cap, making disassembly a simple task. For the 19' SW Shimano lets you order each spool component separately, including the hardened lip, and thanks to this new screw replacing any part has become quite easy.

Another invisible improvement to the spool is a hidden rubber seal beneath the plastic cap to prevent saltwater from corroding the area behind the cap. I inserted a piece of paper behind it and it stops where the seal is located. Of course I'd have preferred a design with no gaps to begin with just like other high-end, but unlike these other reels the cap of the Stella is plastic so there bound to be a gap. In addition to protection from water, this new seal has an inadvertent side effect which I like; it provides firm support for the cap's edge. In the 2013 Stella SW reels (except 30000) the edge of this plastic cap was unsupported and would bend and flex if lightly pushed down which felt very cheap, now with the seal supporting it the cap doesn't bend and feels more solid.

The following is the general drag system layout in 2019 Stella SW sizes 8000 and above. I'll describe the ones in smaller sizes in a little bit.

This is the top stack part of the drag, which is supplementary since the main drag system is at the bottom of the spool. A carbon fibre brake washer, a metal washer, a through pressure tube that applies force to the washers without interfering with the bearing, the top ball bearing, and the stack seal.

This is the actual drag. The familiar clicker system can be seen at 6 o'clock, and it still produces that unmistakable sound of the Stella drag. Spinning reel drags mostly "buzz", "click", "smack", etc., but a Stella SW's drag "rings". Also seen in this photo is the newly added plate hovering over the drag mechanism, labelled "HEATSINK" (heat sink), which comes in sizes 10000 and above. We'll get to it later.

The very intricate sealed drag system, and the bottom ball bearing of the spool sits in its recess. Another new addition here is the heat shield at the bottom of the drag well (red arrow). That shield sits between the spool's flange and the first carbon drag washer in order to hamper the transfer of heat to the flange and supposedly protect the braid from melting. I've never had braid melting on a Stella before and don't know if that's actually a prevalent issue, so it might very well be an answer to a question that no one really asked. It doesn't hurt nevertheless.

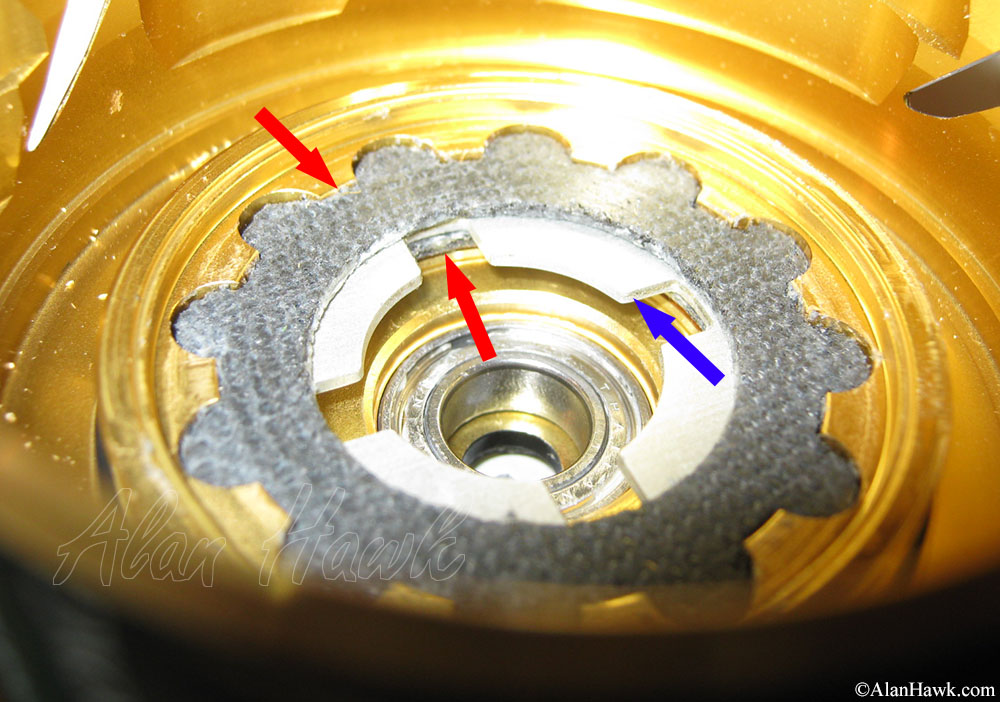

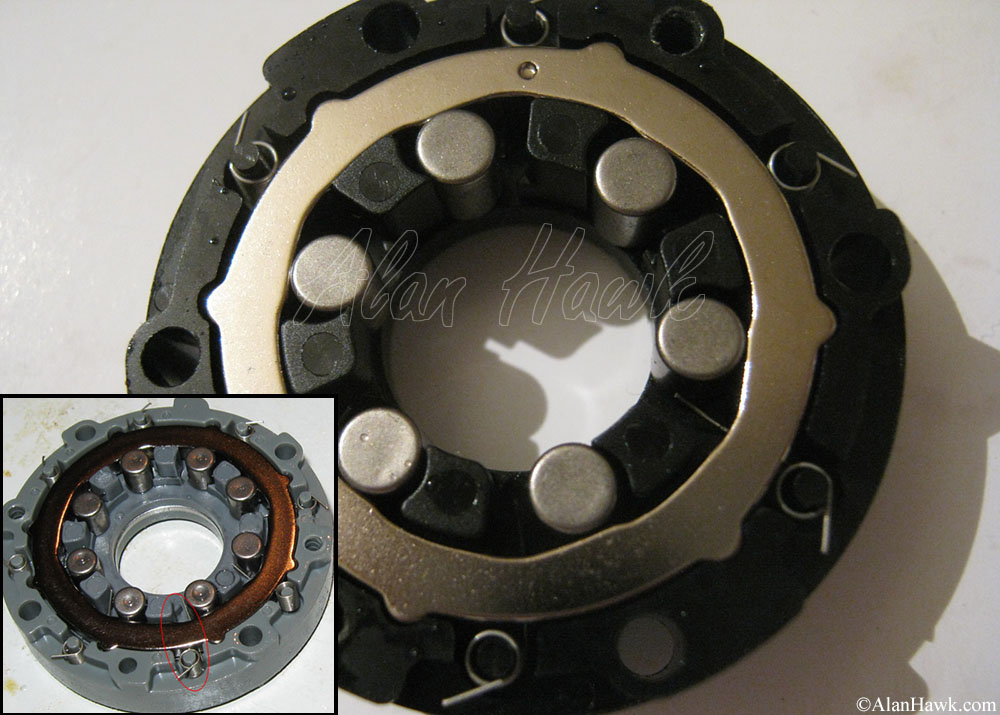

This one shows the workings of the drag setup. The carbon fibre brake washers (red arrows) are keyed to the spool's body, so they always rotate with it. Sandwiched between them is a metal washer (blue arrow) which is keyed -indirectly- to the main shaft. This way when a fish brings the drag into motion both sides of the metal drag washer generate braking force, therefore a single washer does the job of two. Similarly, one final metal washer rests on top of this trio (not shown), thus when the spool spins both sides of the top carbon washer will generate braking, again doing the job of two washers by itself. This smart setup reduces weight by having fewer parts, speeds up heat dissipation, and most importantly fewer carbon washers equals less overall compression. Too much compression is not desirable when the spool sits on a bottom drag stack since this would lower the entire spool when the drag knob is tightened, changing line lay pattern. You know how a 3/4 millimetre spool shim changes line lay dramatically, so you can understand how a little bit of washer compression would have a similar effect.

The new "heat sink" feature is a radiator plate with a flat hub in its centre, that hud is in contact with the last metal drag washer while the rest of the plate spreads into the shape of an umbrella hovering above the drag compartment but touching nothing else. It's drilled to allow air to circulate both of its sides.

This is my clumsy reconstruction of how it looks when assembled. The top metal drag washer is in full contact with the radiator plate's centre hub, and the cross-shaped post on top of it plunges into the rest of the drag washers to transfer heat from the deeper metal washer to the radiator plate. I don't have an infrared thermometer to do fancy laboratory temperature readings, but my observations as an angler suggest that it helps cool down the drag indeed. The maximum drag setting I used in actual fishing was an estimated 12kg (~26lbs), reached only briefly on two occasions while fighting larger groupers, and when I checked the spool shortly afterwards I could still feel some warmth in the radiator all the way to its rim. This indicates that it indeed pulled heat off at least the top metal drag washer. In practice though I did not feel a difference in performance compared to the previous 2 Stella SW generations, which isn't a bad thing since these previous generations had perfect drags that left nothing to be desired. Throughout my tests the drag of the 19' Stella was consistent, smooth, and very responsive, and it continues to be among the few elite drag systems available today.

The drags of sizes 4000 to 6000 are similarly brilliant but the layouts are different. The 4000 has only a top stack drag unit, while the 5000/6000 reels have the main drag unit at the top of the spool with a supplementary one beneath the spool.

Shimano offers an optional "Power Hooking" spool which is designed to have some initial resistance to movement in order to set hooks more decisively, particularly useful when fishing at great depths. I've seen it but did not use it since I'm too busy and too lazy to branch into optional parts. Need to mention that this optional spool does not have the "heat sink" feature, which is quite puzzling to me.

Before moving away from the spool, have a look at this. Usually the inner side of a skirt is left alone, but in the new Stella some very meticulous machining was carried out to remove metal that's not needed from the skirt in order to maximise weight reduction. They even did it in a way that left very handsome ornate patterns, which is some commendable attention to detail.

The convenient and versatile spool shimming system remains the same. Other designs are either worse or equally good, but nothing beats it

The main shaft has changed though. It received a surface treatment that reduces friction. If you see one in a show or a store take the spool off and run your fingernail on the shaft. You'll feel the difference. This new shaft is one component of what they call "InfinityDrive", which I'll discuss further down.

The shaft goes into the body through a seal that keeps water and even urine out. Don't ask me how I know that, let's consider it something I just assumed. On a completely different and unrelated note, NEVER fish on a small boat with a newbie who doesn't know to check wind direction before peeing into the ocean. And another completely random bit of trivia, piss makes your eyes burn so bad you completely forget that some of it got into your mouth as well. @%&#$ HELL!!!

That seal is a hybrid type, where rubber is moulded over a metal washer. This design helps spread pressure evenly across the entire surface of the seal for better sealing, it's less affected by the climate, ages better, and serves longer. Many of the seals used in this reel are of this type.

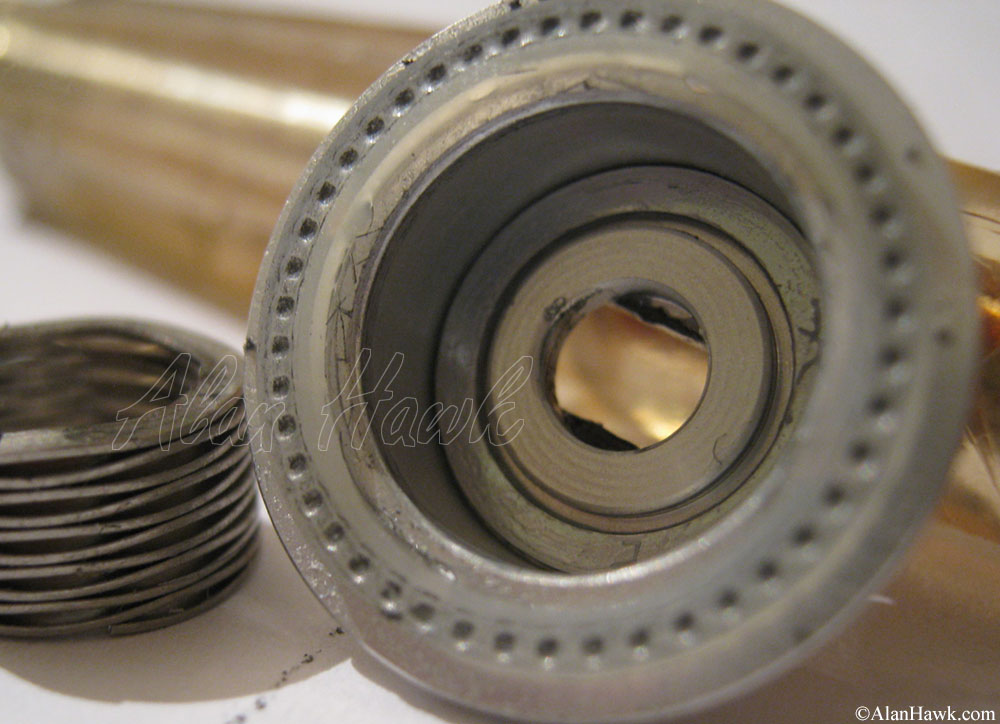

The rotor nut, and in its centre the first half of the floating shaft mechanism; a ball bearing to isolate the shaft from the rotation of the rotor, and inside it a synthetic washer to reduce friction with the shaft during its up and down movement.

Beneath the rotor nut sits an O ring seal.

To reduce the weight of the metal rotor, a part of it was removed and replaced with this light silver plastic top. It doesn't do any work nor bear any load, and its only task is to fill the void so that if the line gets behind the spool it doesn't wrap around the shaft. It has two cuts to allow water to drain out if the reel gets too much spray.

That silver top is screwed to the rotor, and the screws go into metal posts extending from the rotor all the way through each hole, so that screw heads would tighten against the metal posts and not the plastic top itself to avoid accidentally cracking it.

That's the working aluminium rotor, and it's quite different to previous models.

This is the main difference. Bail mechanism has been moved to the opposite rotor arm, which is something that Shimano has been doing in a few other models for 2 or 3 years now. In the classic rotor design, one side of the rotor has both the bail arm and the bail mechanism, therefore more material would have to be integrated into the opposite side of the rotor for no other purpose than to balance it out. By moving the bail mechanism to the opposite side, weight would be evenly spread and that extra balancing weight wouldn't be needed. If this seems confusing, think of it in terms of apples and oranges. Imagine a rotor that is completely empty and balances on its own. Then you add two oranges to one of its sides, and now you need to balance them with two apples on the other side. Then remove one orange and hold it in your hand, consequently you'll have to remove an apple from the other side and throw it away to balance it. Next remove the other apple and throw it away, and put the orange that's in your hand in its place. Now it balances again with two apples out of the picture.

With the bail mechanism on the other side of the rotor, the bail wire needed to be more firmly fixed into the end piece which now holds the spring power, so this deep deep indentation was employed. I mean that thing is so deep you can fill it with water and keep live bait in it. Well, not really, but you get the idea.

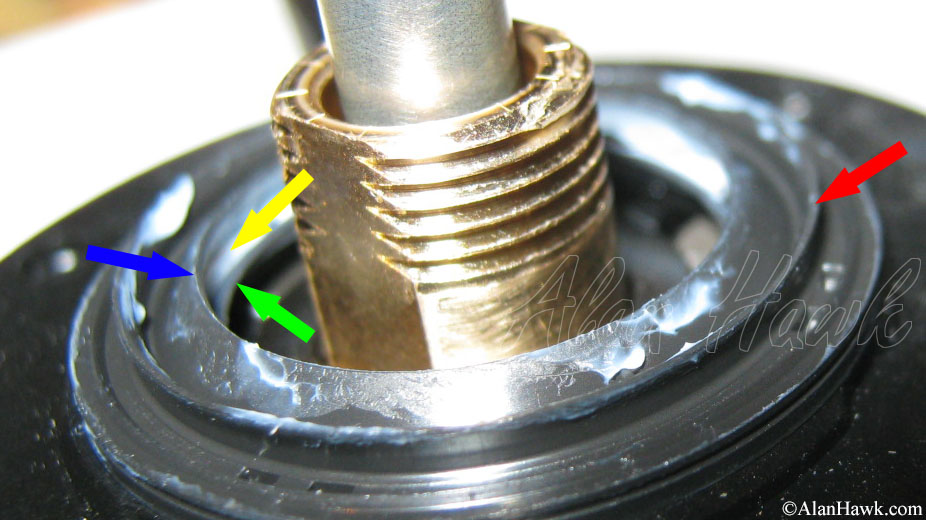

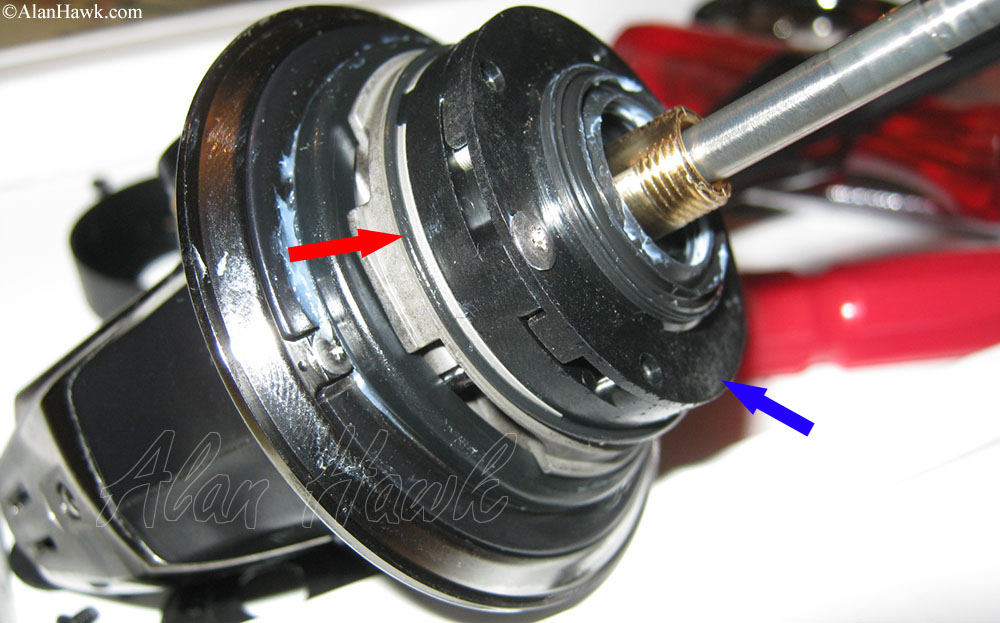

Looking behind the rotor reveals the several stages of water protection this area has. The new silver flange shield (yellow arrow) reduces the gap between the rotor and flange making it harder for water to get in. Water that does get in would then have to navigate a U shaped narrow maze formed by the standing wall (red arrow right side) fitting into its groove in the rotor (red arrow left side). Any crafty bits of water that pass these hurdles would then have to face the 4.stage seal (blue arrow right side) which fits tightly around its sleeve (blue arrow left side). I left that sleeve attached to the rotor to show its working position. There is a hidden O ring seal between that sleeve and the rotor's neck.

Closeup on the 4 stage seal. It begins with a wall (red arrow) that curves backwards to trap small amounts of water and keep them from going further. If there is too much water for this wall to handle, water will be met by the upper lip of the seal (blue arrow). That should be the end of it, but in cases of high water pressure some of it might still pass the lip and be met with the 3rd stage which is the grease-filled compartment (yellow arrow). Beyond that there is a final seal lip (green arrow), but I can't imagine it ever being needed unless the rest of the seal is physically damaged or something. This very effective sealing debuted in the 2013 Stella SW then quickly trickled down to other models further down the line, most notably the 2014 Saragosa SW and 2014 Spheros SW, both of which have the exact same arrangement including the U shaped maze.

Now that's a surprise, and not the good kind. The 19' Stella SW comes with an externally mounted, plastic housed anti-reverse clutch. Yep, the design that for the past 18 years has been relegated to lesser Shimano reels from the Twin Power SW all the way down to the $35 Cazna FA.

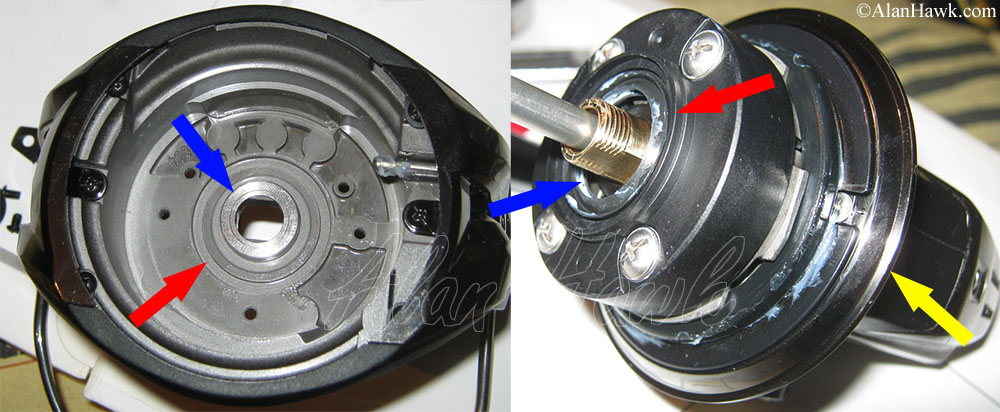

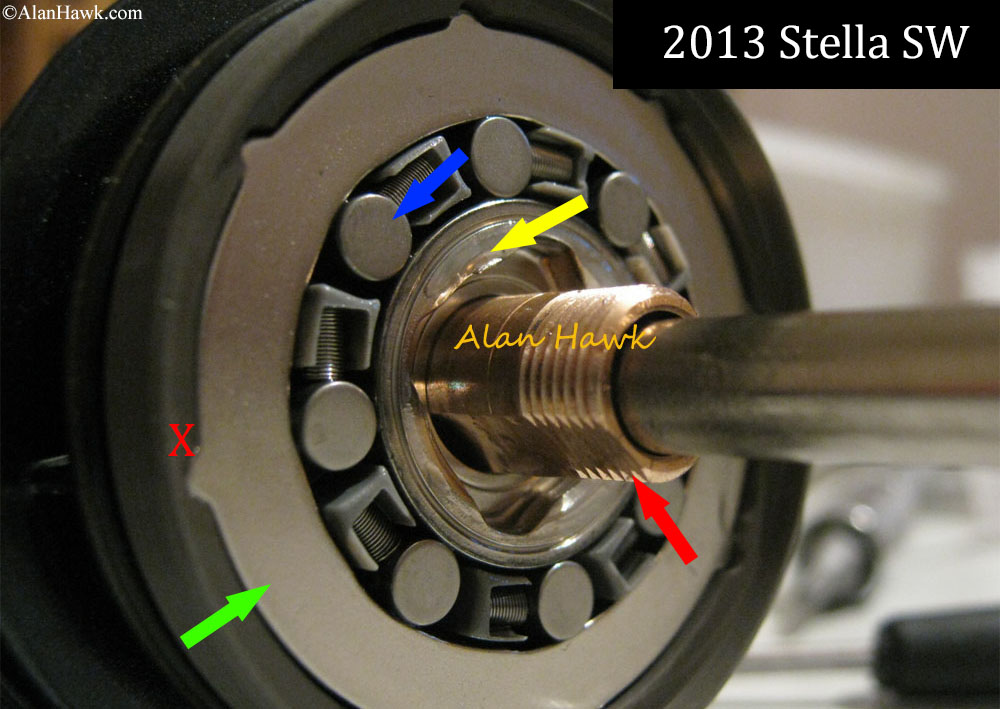

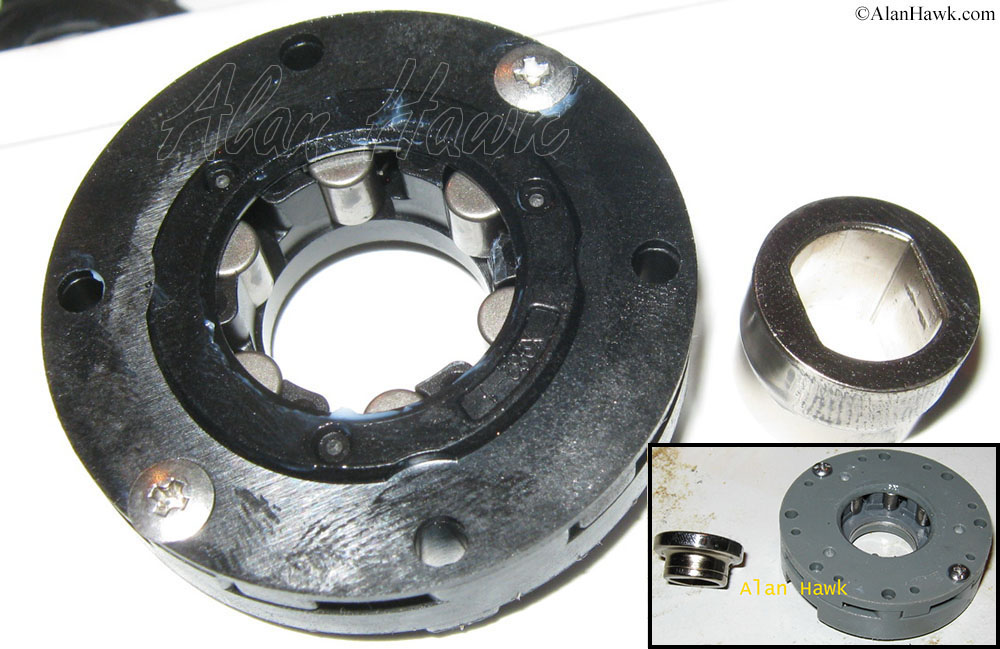

Let me elaborate on why I believe this to be a severe downgrade; the anti-reverse clutch is one of the most vital parts of any spinner, coming under tremendous stresses as it holds the rotor still against any given amount of drag pressure. Accordingly, the way the clutch is attached to the rest of the reel plays a major role in determining the reel's ability to withstand these stresses. The following photo is borrowed from the 2013 Stella SW review

It was done right in the 13' Stella, and that's the way it's supposed to be done in heavy duty saltwater reels. During a fight, the torque on the pinion (red arrow) is transferred to the stainless sleeve (yellow arrow), which in turn wedges the stainless steel brake cylinders (blue arrow) against the stainless steel clutch ring (green arrow), and that ring is keyed directly to the metal frame of the reel (red X). The plastic spring cages in the middle have no role in this, they just hold the springs. See how it plays out? Load is resisted by an uninterrupted chain of connections between solid metal parts, ending with the powerful grip of the metal frame of the reel itself.

This is how Shimano did it in its Stella SW reels beginning with the 2001 Stella SW (FA), how Daiwa have done it in its flagship saltwater reels since late 1990s, how the original Penn Torque 1 did it, how the Makaira does it, and how every proper big game spinning reel does it. In one form or another it's always a set of uninterrupted metal to metal connections from the pinion to the frame. And yes, in the previous 3 generations of Stella SW all sizes had that, including even the tiny 4000. Let's peel more layers

In previous generations the internal clutch assembly was covered by a metal cap screwed directly into the body, now the external clutch is covered by a plastic cup that has 4 screws instead, identical to the setup found in the 2014 Spheros SW and 2014 Saragosa SW. The screws have mounted O rings to keep water out, again just like the Spheros/Saragosa.

Beneath that plastic cover sits the plastic clutch housing (blue arrow), and the red arrow points the cover seal. Once more everything matches the Spheros/Saragosa.

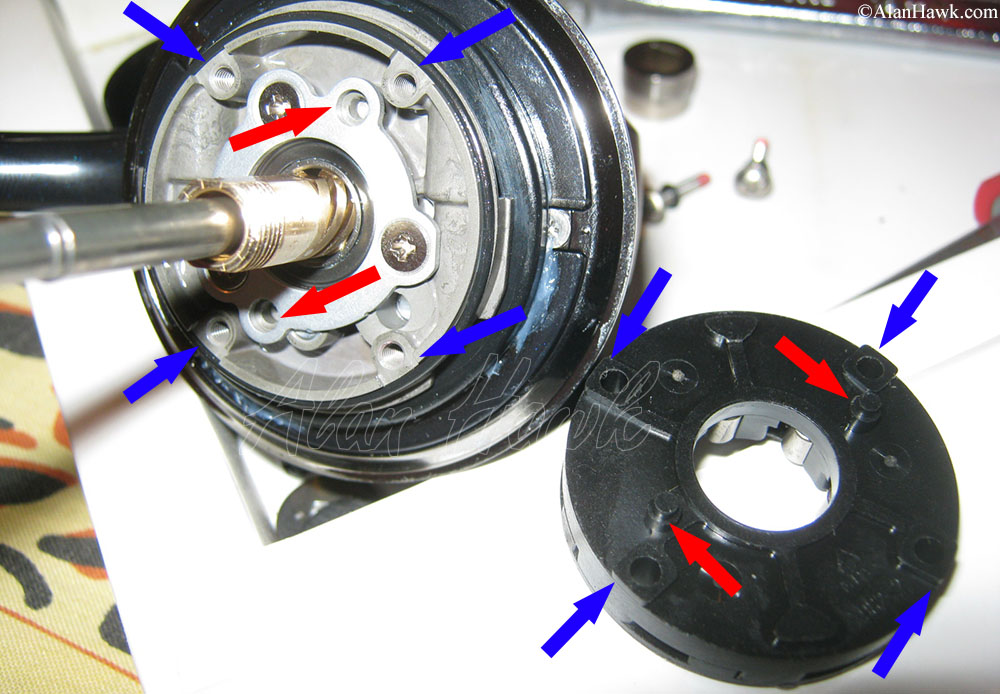

Here is the 19' Stella SW's clutch, the same design used all the way down to entry level reels. I inset the clutch of the Spheros and Saragosa in the bottom right of the picture so you won't think I'm exaggerating. The different number of brake cylinders is due to different size classes, the one inset being from 20K Spheros/Saragosa.

Cover off, and again I inset the one from the lesser reels. Same design, same springs, same operation, same everything. Look at how the main clutch ring is now keyed to the plastic housing, instead of being directly keyed to the metal frame as in the past.

And this is how that plastic housing itself is attached to the body; a series of moulded plastic protrusions that mate with notches in the reel's frame and bearing cover as arrows of similar colours indicate. No direct connection between the clutch ring and the frame, instead plastic bits do that job and 4 screws press down on the whole thing. These are the facts and you can feel about it as you will, but my own opinion is it's a big leap backwards which erases much of what used to set the Stella SW reels apart from lesser models. Yes, this design was once in the 1998 Stella SW (Stella F), but it's 21 years later and the demands and expectations from heavy duty reels have dramatically changed.

This clutch does its job in the 19' Stella and stops the rotor, albeit with what I feel is unmistakable sponginess instead of a firm stop. Don't take my word. Find one, hold the rotor and turn it backwards against the clutch, and see for yourself how much give it has. I definitely prefer the solid stop and -more importantly- the security of the redundancy of strength offered by the full metal grip of the 3 previous generations. Turns out it's a good thing that the 19' Stella does not produce the claimed drag pressures, because I believe that this clutch would be in serious trouble if subjected to those claimed numbers. There is a good reason why Shimano itself decided to replace this design with the full metal grip almost 2 decades ago and relegated this one to lesser reels and lighter duty freshwater ones, so in my opinion this is inexcusable. Moving on.

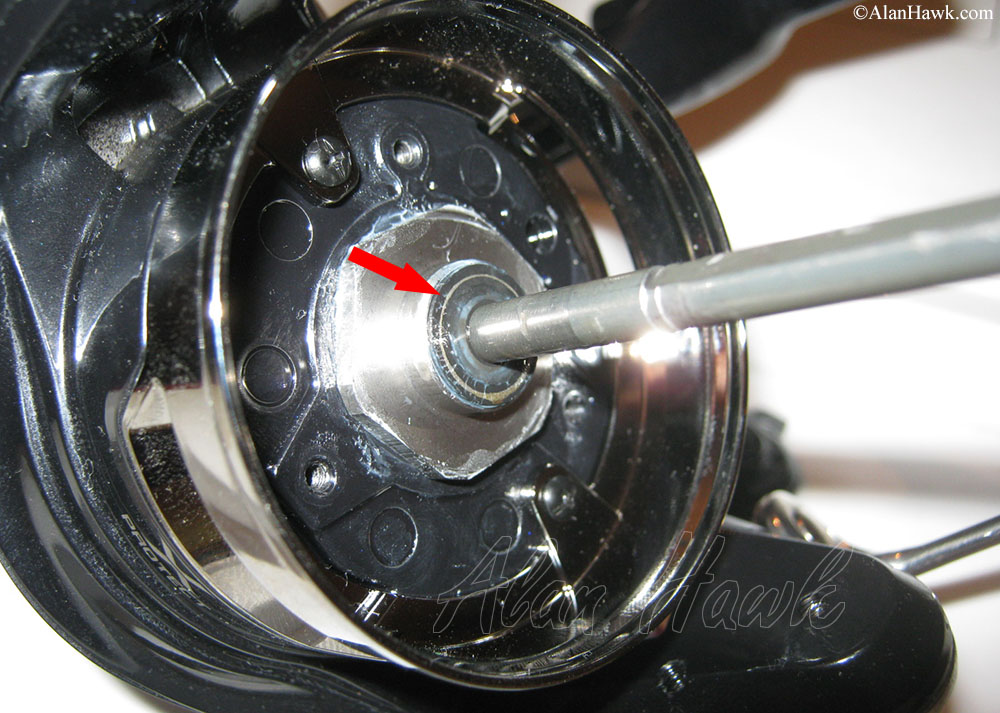

The main ball bearing now goes directly into the frame in the mid-sized 8000/10000/14000 which is an improvement over the previous generation. If you recall, 6 years ago I found the rotor of the 2013 Stella to be unstable and shaking too much, and concluded that it stems from an extra ring installed between the bearing and the frame in sizes 8000 and up of that 13' model. I inset that part from the 13' Stella review in the picture for guidance, and you can read it here. That ring is now gone in the mid-sized 19' Stellas and their rotors are stable, and while the ring remains in bigger ones the tolerance is certainly better and there is barely any play. Respect to Shimano for making things right.

To get inside the gearbox a few pieces need to come off, including the rotor brake ring which is new to this size class. Previously 8K/10K/14K reels had "toothed" rings that would get captured by the brake lever then slide on the frame, now this medium size class comes with a fixed ring against which the brake lever rubs just like in larger 18K/20K/30K reels. Sizes 4K/5K/6K of the new Stella SW still have the toothed ring though. Both designs work fine, but I find the fixed ring to have a slightly stronger grip on the rotor.

For those unfamiliar with rotor brakes, these are mechanisms that hold the rotor still once you open the bail to make a cast. Their purpose is to prevent the rotor and handle from moving as you swing, which could sometimes lead to a disastrous bail closure in the middle of a cast. This is particularly important in reels that have an auto bail trip, meaning the bail can be closed by turning the handle. In the 19' Stella sizes 4K/5K/6K have auto bail closures, the others have bails that close manually.

The plastic rear body bumper also needs to come off. Another change seen here is the new location of the draining slots further back, which makes more sense and allows water to drain out when the reel is held at an angle as in during active use, or when it's vertical as in a gunnel or a rod rack. The previous location of these slots only allowed water to drain out when the reel was horizontal or near horizontal, so this is another improvement.

To remove the top screw of the rear body bumper this rubber plug needs to come out, and a straightened hook does the trick every time. After taking this photo it hit me that when I reviewed the previous version 6 years earlier I also used a straightened hook to remove that plug and took an almost identical photo, and it's all completely coincidentally. Sitting in the same garage, on the same chair, removing the same part the exact same way and taking a nearly identical photo, but between these two very similar moments 6 full years of travelling to far corners of the world, meeting hundreds of new people, buying loved ones, victories and defeats, almost dying once, yet I'm back as if I've never left that original moment. I wonder what will happen between now and the time I take apart the next generation, or if that will even happen at all. Life is weird, isn't it?

With the plug gone, the top screw of the body bumper can be reached with a small Phillips screwdriver.

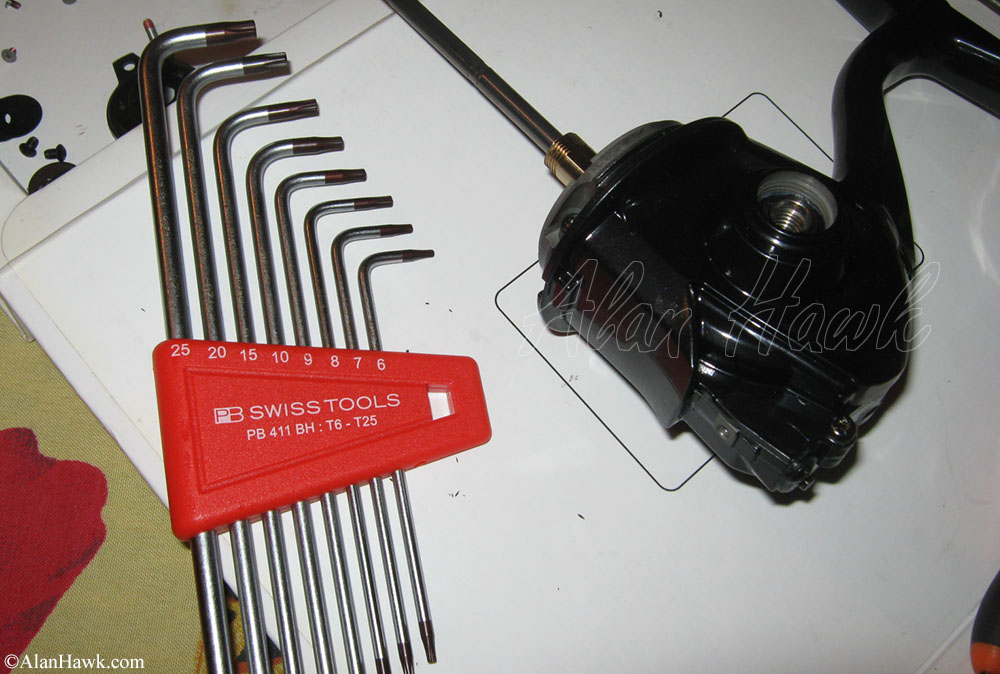

The body screws are Torx type, and the two front ones are very long, fit tightly, and have a lot of Loctite applied to their threads. Use high quality wrenches not to risk damaging the screw heads. I invested in the best tools money can buy after a few close calls in the past years.

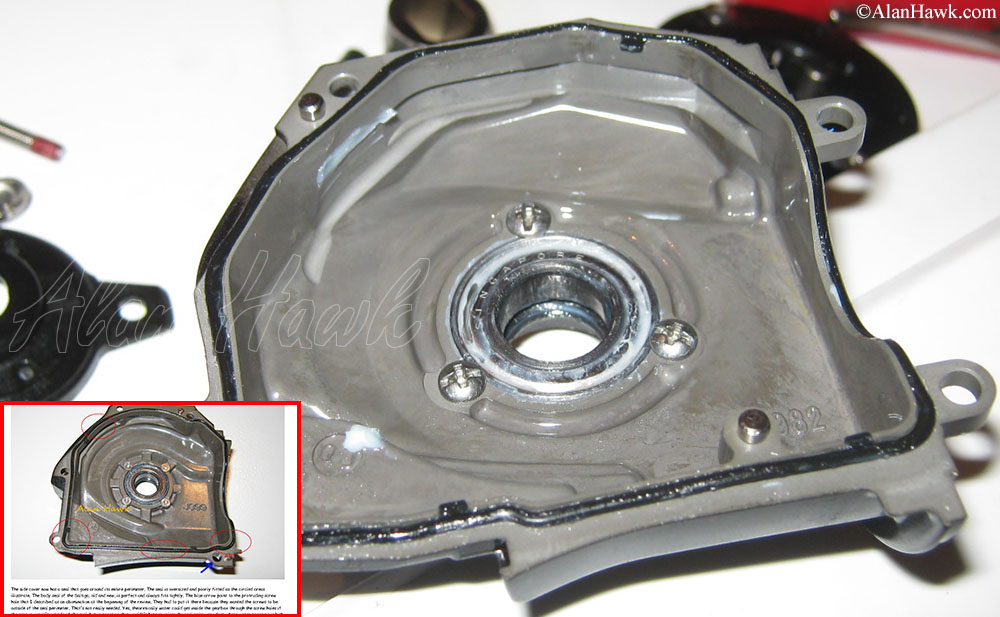

Side cover off, and immediately saw that the perimeter seal fits well. In 2013 I criticised the loose fit of this seal in the previous model (inset), and certainly glad it's been rectified. Seen in this photo as well is one of the drive gear's ball bearings, held down by three screws to maintain pressure on the seal beneath it.

Here is that seal with its adjusting shim and the bearing

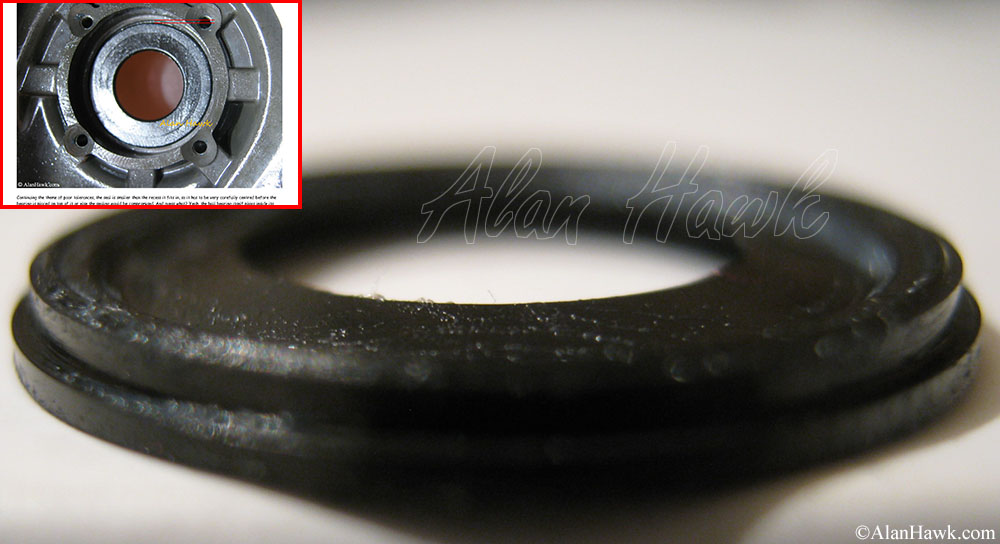

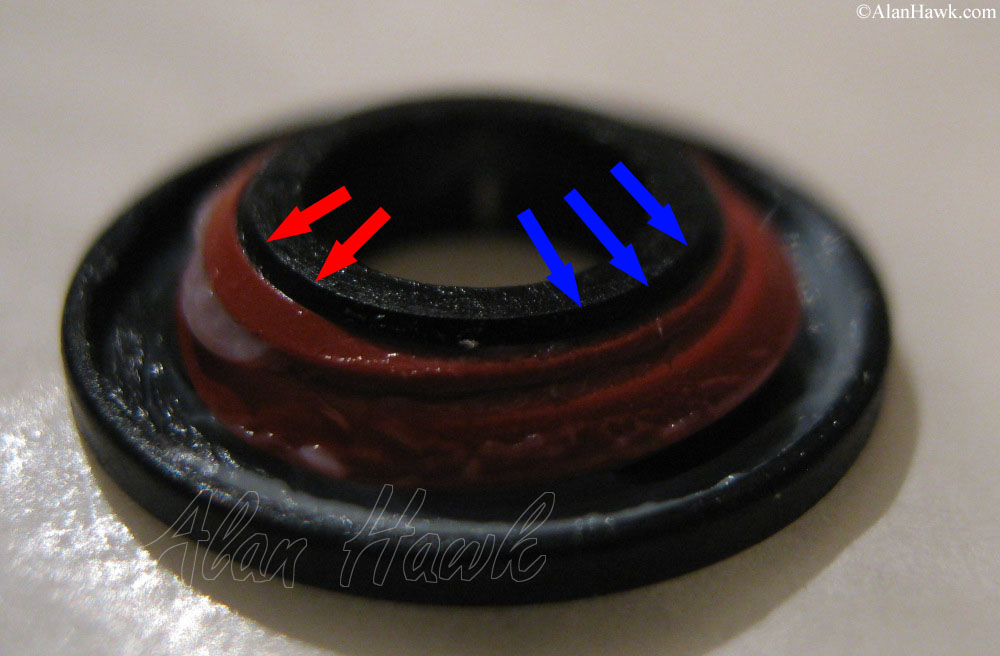

In the 13' Stella review I complained that this seal was a basic flat piece of rubber that was undersized and played in its recess potentially compromising the sealing. A screenshot of that part from the review is inset. In this new Stella I was happily surprised by the decisive and comprehensive manner they addressed this. As seen in the photo, that piece of flat rubber is now gone and a new 2 level self-centring seal takes its place, but that's not all...

Turning the seal around reveals that it's a hybrid rubber/metal type as well. Now when the seal is dropped in place, its two levels slide into their perspective recesses automatically centring it, then when pressed by the shim and bearing the metal component of the seal distributes pressure evenly across its surface providing an excellent seal. Apparently I offended someone with how I trashed the old seal in 2013, and sure glad I did!

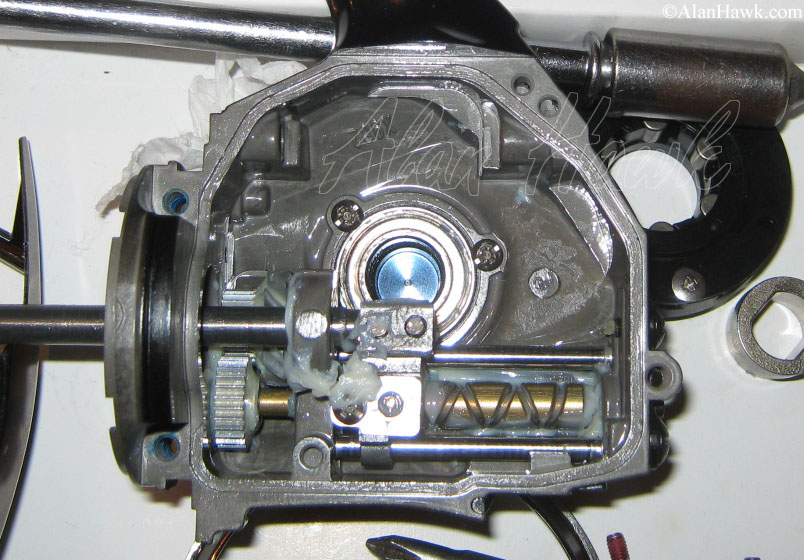

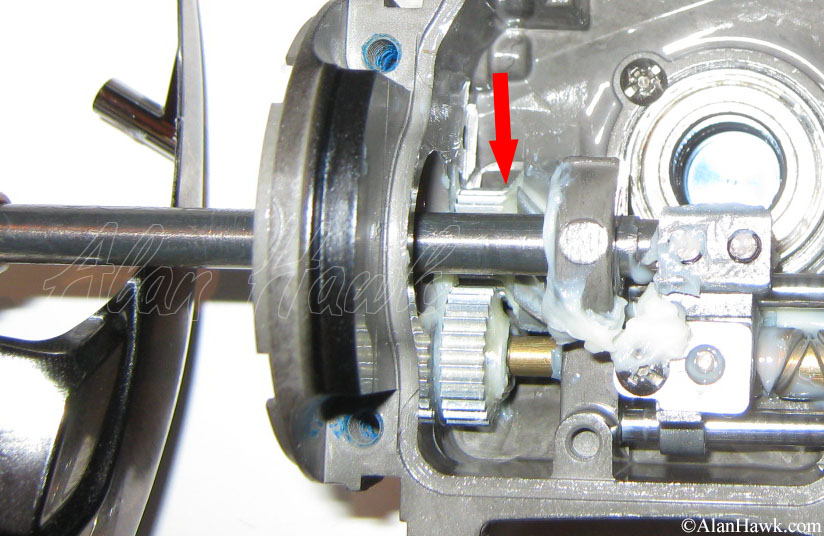

A general view of the gearbox. Notice anything? The backup anti-reverse is gone! In both 2008 and 2013 Stella SW generations, sizes 8000 and up had a mechanical backup anti-reverse which would automatically engage and keep the reel usable if the clutch slips for any reason such as very cold weather, lube contamination, or normal wear and tear. This backup anti-reverse is gone from mid-sized 19' Stella SW, and is only present in the big reels, exactly like the 2014 Saragosa SW. This depresses me so much I can't even gather enough energy to be angry. There is simply no excuse for this in a reel that costs a thousand dollar and is supposed to be one of heaviest duty spinning reels available. Omitting such an important fail-safe mechanism is shameful and inexcusable. Sadly though some have tried to excuse it, and since it's been more than a year since I initially posted this and I got to see all the excuses, how about playing another round of "debating the imbeciles"?

- Imbecile: That backup is a waste of money, no one ever needed it.

- Response: why then was it in 2008 and 2013 Stellas? Was Shimano into the business of wasting money from 2008 till 2018?

- Imbecile: The external clutch is super duper reliable and it needs no backup.

- Response: then why exactly is that backup present in sizes 18K/20K/30K which have that same clutch?

- Imbecile: It's not needed in the medium reels, but it's needed in the big reels that handle heavier jobs.

- Response: but according to Shimano's own claims the difference in maximum drag between mid and full sizes is only 3 KG (6.6lbs) and in practical drag they are only separated by 1 KG (2.2lbs). Will the measly 1 to 3 extra kilos of load overwhelm the clutch and require a backup in big reels?

- Imbecile: It's a big company, lots of money, smart engineers, they know better than you do.

- Response: aaaand here comes again that beautiful, sexy, sensitive woman inside you. Go for the surgery, be your true self, and maybe then you can find a husband who would step in for you and debate with reason and facts instead of helplessly appealing to some vague superior authority. With him around doing the debates you'd even have more free time to shop for pushup bras to accentuate your allure.

See how that game is played? You don't make any statements or provide any facts, because the imbeciles would then dispute your facts and a general audience that comes from all walks of life wouldn't know what to believe. You simply dig logical holes in their own arguments and show their contradictions, and when they claim that what's being done now is "so obviously the right thing", you innocently ask if that means that what was being done just a few years ago was "so obviously the wrong thing".

Anyway, the omission of that backup is in my opinion an absolutely disgraceful effort to cut corners and it's worthy of nothing but contempt.

I would've preferred to see this intermediary set of gears gone and the backup anti-reverse kept instead. This set tunes up the oscillation stroke, but I don't recall the great 2008 Stella SW suffering for not having it. For it to be kept and the backup brake thrown out is unfathomable to me.

The drive gear no longer has the little hub that used to house the backup anti-reverse activator spring since there isn't a backup anymore in the mid-sized reels. It is the well known aluminium alloy gear plate that's formed by cold forging before it receives a surface coating for durability then a stainless steel female shaft gets embedded into it. One of the most proven parts, and it offers an admirable combination of lightness and toughness. Shimano has mastered the art of cold-forging light alloys into tough gears, which have now trickled down to many salt and freshwater reels further down the line all the way to entry level ones. Without that sort of manufacturing ingenuity we wouldn't have such magnificent spinners as the 2014 Spheros SW, which at the time of writing remains the reel I recommended more than any other in the past several years with hundreds of results coming back when I search "Spheros" in my email outbox.

No surprise here. After almost 110 hours of actual fishing time the gear remains in pristine condition, very little wear, no chips, and full structural integrity. I intentionally left some grease around to show you how clean the lubes remained, often a good indication of durability and absence of galling. The reddish spots you see are a by-product of the surface treatment. Evenly distributed, perfectly harmless and nothing to worry about at all.

The pinion is machined brass. Since friction wear is a reciprocal relation, it was only normal for the pinion to be in the same great condition as the drive gear. Very little wear relative to the use I put on it. This gear coupling is by no means the toughest in the industry, but it offers a great balance of good durability and smoothness of operation. With use the reel loses some of its initial smoothness, which is normal, but even with that it remains smoother and quieter than most saltwater reels out there.

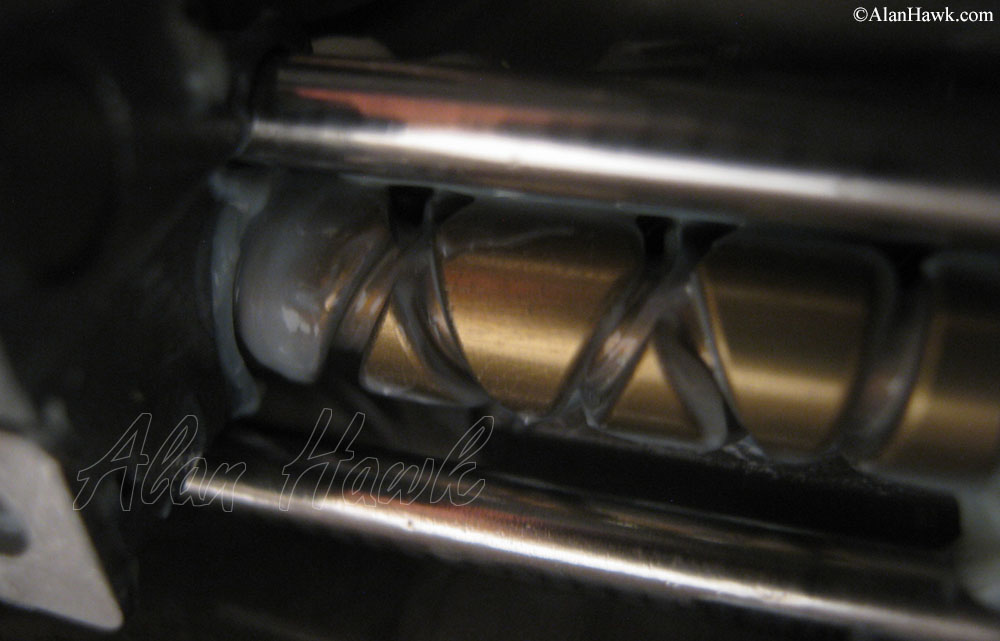

This new oscillation worm shaft is heavier than its predecessor, but much tougher as well. Having cut weight with the external plastic-housed clutch they could afford to employ this bronze worm shaft without worrying about its weight. I've tested some non-mainstream reels that had stainless steel worm shafts, but the steel alloys were not particularly of the highest grade so I'm placing the new Stella's worm shaft ahead of them. Look at this close-up showing the crisp edges and tips inside the grooves, an instant telltale of toughness. In addition to longer service life, this shaft has a lower coefficient of friction against the pawl, which improves the overall smooth running of this reel.

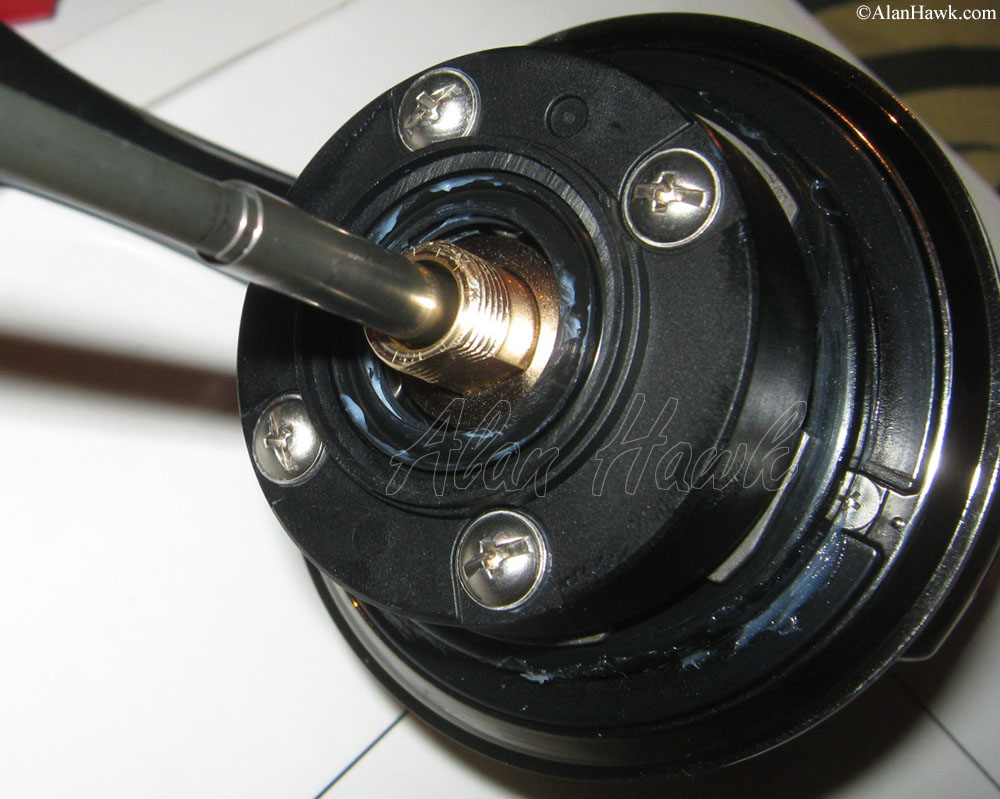

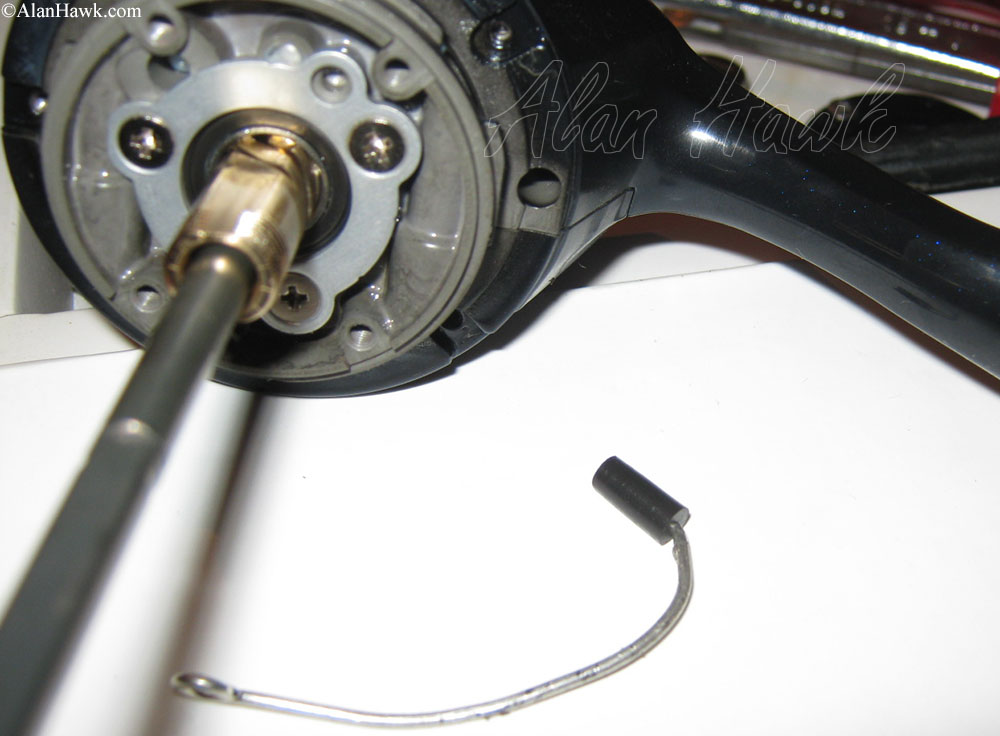

The retention of that worm shaft changed as well, and commendably so. The first indication of a change is the plug sticking out of the retainer plate.

This plug. In previous generations there was a rubber seal that sits beneath the retainer plate, with a hole in it right above the worm shaft. That setup wouldn't allow a very accurate shimming of the worm shaft and its bearings, resulting in a tiny amount of play back and forth in that worm shaft. In this new design though the plug itself has a mounted O ring seal (red arrow), as well as a dual-washer shimming system. One of these washers is a standard flat one (blue arrow)...

...and the other is a spring washer. Being a spring allows it to self adjust and fill any space, preventing even the slightest play in the worm shaft.

Here is that spring washer when installed on top of the worm shaft's ball bearing, precisely pushing on the outer race of the bearing but not touching the inner race to allow it to spin freely. I know that I'm getting into the most minute and almost microscopic details here, but people worked on these tiny details and they deserve to be acknowledged. This improved retainer design came to life shortly after the release of the previous Stella SW, I first saw it when I tested and disassembled the 2015 Twin Power SW, and it's only natural that it would make its way into this latest Stella.

The two stainless rail rods on which the oscillation block slides have pointy ends to save a tiny amount of weight, and each has its mounted O ring seal to keep water out (not shown). One has to admire Shimano's persistence in employing worm shaft oscillation despite its complexity and the difficulty involved in fine tuning it. At this point I believe it's just a matter of upholding a tradition, because today the best locomotive oscillation setup beats the best worm shaft oscillation one in terms of strength, longevity, efficiency, and it can produce the same amount of spool lift in standard reels. The only place where worm shaft oscillation remains indispensable is long distance long spool reels. I'm happy with it nevertheless for the sake of diverseness. Life would be pretty boring if every brand used the exact same design and every reel I opened looked the same.

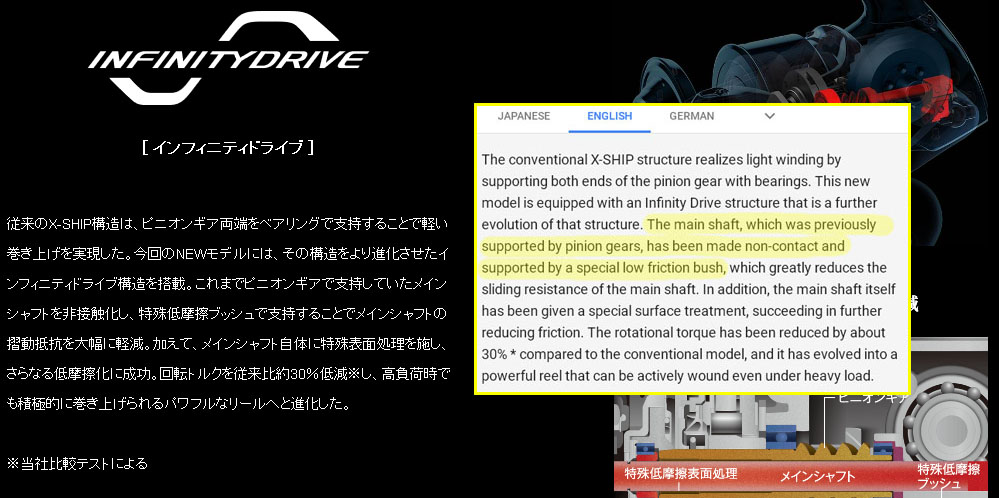

Now get ready because you're about to witness one of the greatest technological advancements of all time. A true groundbreaking and earth shaking scientific leap that makes the Hadron Collider look like a laughable school project by a 4th grader. Behold the "InfinityDrive"! Even before getting into the details, one can't help but feel the weight and magnitude of this feature merely by hearing its name. It's "infinite", and it "drives" the reel, something that leaves no doubt that the principles of conservation of energy have been chattered, that known laws of physics have been broken, and that Isac Newton and Stephen Hawking are about to receive a rude awakening. Finish whatever you're doing because it will take a couple of hours to explain, and maybe I'll write a series of 7 or 8 reviews to hopefully just barely touch on the intricacies of this gem...

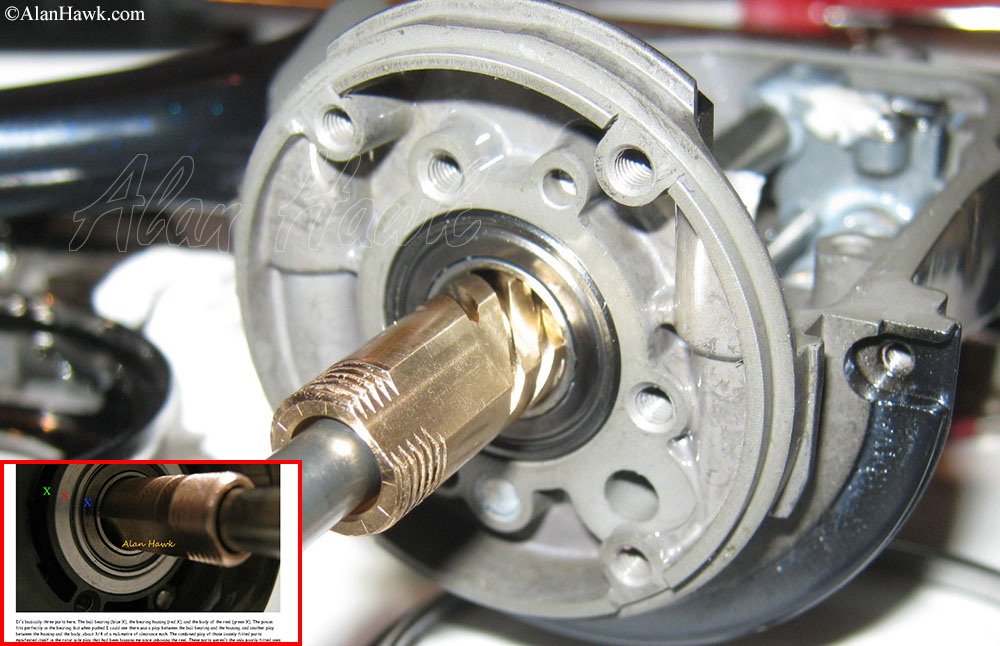

Well, not really. The core of the "InfinityDrive" is this sad looking polymer bushing inserted into the mid-post.

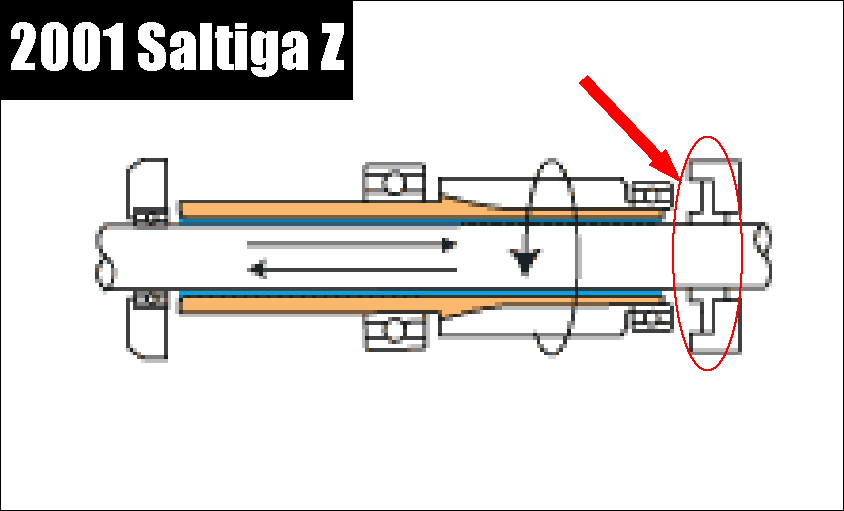

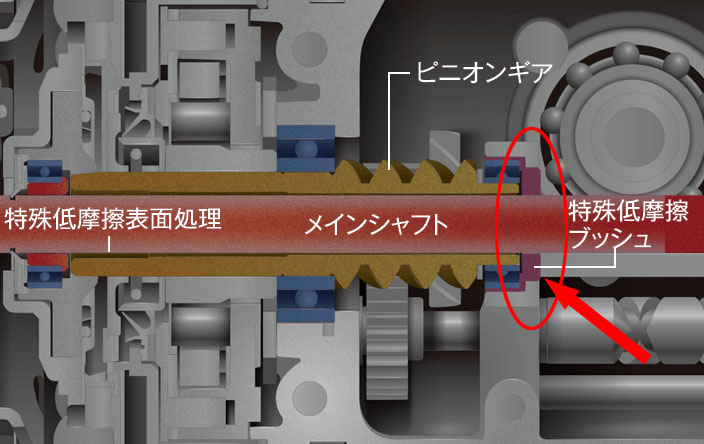

Here is a screenshot from Shimano's own site, and I imposed Google's translation on it so I wouldn't be injecting any of my own words. There you go, the InfinityDrive system is in essence a bushing that supports the coated main shaft on the inside. I did some digging in my old folders, and found this

This is from the promotional materials released with the Saltiga Z back in 2001, in which they highlight a bushing inserted into the mid-post behind the bearing to support the shaft. Compare to the following image from Shimano's explanation of their spanking new InfinityDrive

Do you want my uncensored opinion? The way I see it is that Shimano shoplifted something that Daiwa introduced almost two decades earlier and called it a scary elaborate "sciency" name, which is absolute bollocks!

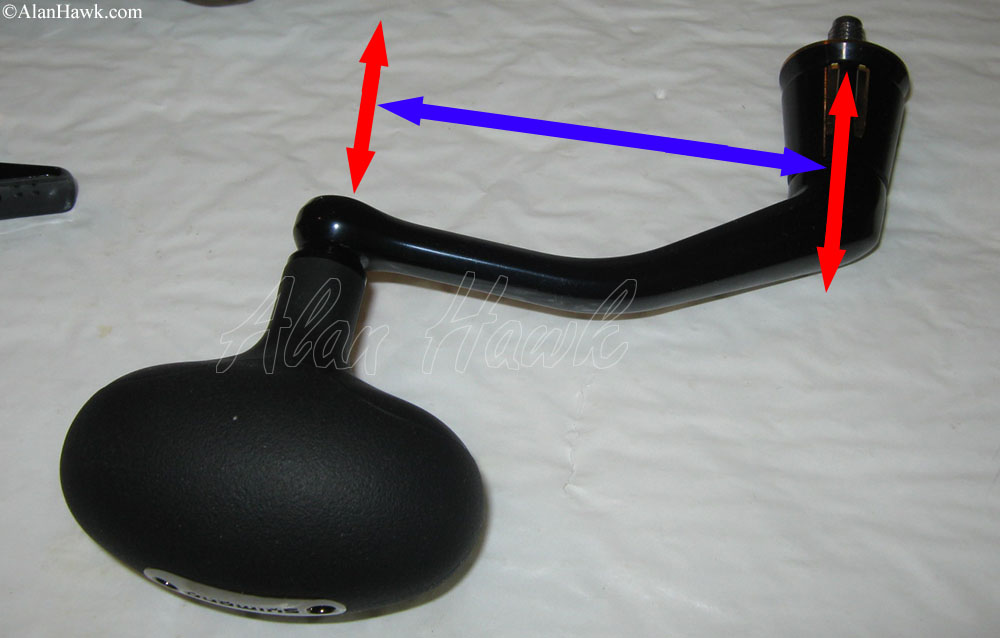

The new black handle, and as usual sizes 8000 and up require you to swap the small threaded shaft in order to change the winding side. Sizes 4000, 5000, 6000, and 8000 come with a ball handle knob, while 10000, 14000, 18000, 20000 and 30000 come with the oval knob. Shimano therefore assigns the knob type based on size regardless of the speed, which is pretty interesting. The hood of the new handle looks better, and the asinine steel tube of the previous model is gone. Not only was that tube ugly, but it was heavy, and I found it completely useless as well.

I inset the part from the previous model's review where I ripped that dumb design. I believed that the steel tube failed to support the joint despite what was suggested in the animated promotional videos, and pointed out that it only abused the poor joint and damaged its finish. Those dumb fantasies have been dropped, and instead the 19' Stella has a clean practical design based in reality. As seen in the photo above the threaded shaft now sinks into a recess machined into the stem, where it's fully enclosed and supported by solid metal on all sides. Vastly superior to the previous design where the shaft was retained by an unsupported fully split post.

Okuma beat them to it by a few years. This is a foolproof design for the joint and I wish Shimano would stick to it instead of trying to reinvent the wheel. Just like the discarded parallel foot, it doesn't inspire much confidence to come up with a steel tube in the handle's joint and tell us in flashy animations that it's the best thing since salted crackers only to discard it completely on the next update. Sometimes I think that they change designs purely for the sake of making new flashy animations, not the other way round. Meh!

I chose the 14000XG for my tests for two main reasons, firstly, it was one of the earliest models released, and secondly, because its handle is 5 mm (~0.2 inch) longer than the typical handles of this size class. All other mid-sized 19' Stellas have 75 mm long handles, including my reel's twin sister the 14000PG, but my 14000XG has an 80 mm handle which aroused my curiosity...

Putting a longer handle on the fastest reels gives users more leverage which translates into more torque generation. That would compensate for the lower torque produced by these fast reels. As you might already know, reels with slower gear ratios produce more torque, while ones with faster gear ratios will generate less torque. It's the same as in a car where the first gear will produce high torque to get you going, then as you move the stick to higher gears you get more speed but less torque. That's assuming that you kids even know what a stick shift is to begin with. You see, a stick shift is something we had to learn in order to drive cars, back in the good old days when we did real activities and had actual social lives where we stole liquor from our parents' cabinets and snuck out at night to party with real girls in the woods, trying desperately to get into their pants pretending to be confident and experienced even though we had no clue what we we're doing and usually panicked once those pants came down for real. We did not sit all day on social media getting offended and telling the world about it then swept left and right through mostly fake profiles run by Nigerian scammers in hopes of landing a date with an equally offended girl, so we could meet up over $7 cups of stupid cinnamon mocha frappuccino to discuss how supremely offended we both are. But I digress.

What was the subject again? Yeah, long handles. I'd be very wary of the willy nilly use of longer handles in high speed reels for more power since it could cause more harm than good. You don't deal with the lower power of speedy reels by permitting the user to overstress the drivetrain with a longer lever. Instead you increase power by improving efficiency, refining the gear geometry to maximise rolling and minimise sliding, reduce gear offset by using a thin male gear shaft like Daiwa does, etc. Unless the reel has extraordinarily beefy gearing, which isn't the case with the 19' Stella, it's better not to stress the gears with that extra leverage of the longer handle.

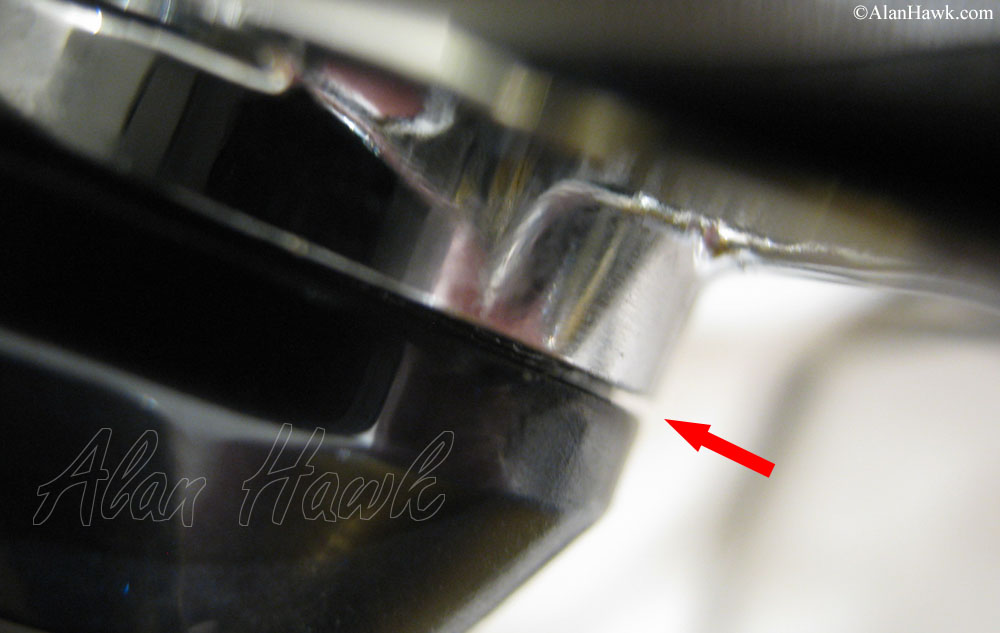

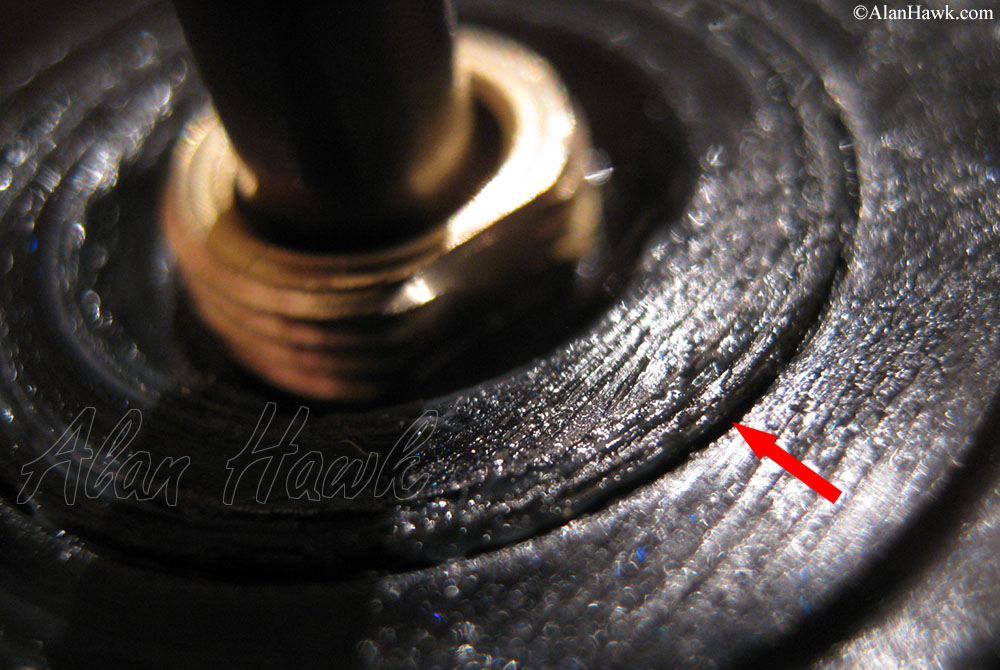

The line roller is yet another part that fundamentally changed. Not as much externally, but inside it's completely different.

In previous SW models the line roller itself was not sealed, but had two rubber-sealed ball bearings inside. The aim was to make the line roller spin with as little resistance as possible, and the tiny rubber seals inside the ball bearings produced very little resistance compared to potential larger seals for the line roller itself. They gave that up in the 19' Stella SW, and decided instead to seal the line roller itself with rubber seals just like Daiwa did in the 2001 Saltiga. In the photo above you can see the two new rubber seals (blue arrows), which fit onto corresponding bushings at both sides of the line roller (red arrow). Look at that bushing inside the line roller though. Can you spot it?

The internal O ring that goes between the bushing and the roller's body escaped its recess during assembly and got wedged like this.

Here is the bushing and the O ring after I pulled them out. Both are made very well to exact tolerances, but accidents during assembly do happen.

Here it is back on its mount, and I have to say the level of detail on such a small scale is impressive.

That wasn't the only assembly issue. The red seal that goes into one end of the line roller was not fully seated into its recess on the hub.

Here is the hub without the seal, again showing some impressive details on a very small scale.

And the red seal that goes into the other side of the roller was not seated correctly as well, indicative of a general issue at the assembly line. Excuse the lent, I had tried to rest it on a piece of white fabric to get the camera to focus for this macro shot.

Here is a side view showing the effect of a non-fully seated seal. Its skirt, which does the sealing, is at an angle potentially compromising the sealing and causing premature and uneven wear. Again, all the parts were manufactured correctly, and once I fully seated both seals with the aid of my trusty loupe and a toothpick they remained in place. These all look terrible, but they really aren't. In years of doing this I've come across many assembly faults in some of the most expensive reels, including a 2015 Saltiga that had a dislodged O ring beneath a mag-sealed bearing and a 2008 Stella SW that was missing the tiny plate that retains the line roller screw, just to name a couple. These things happen because reels are assembled by humans, and the issues in the line roller of the new Stella are particularly forgivable considering all the tiny recesses and very intricate parts requiring extra care in assembly. Hopefully by bringing this to light this early some corrective measures would be taken.

And these are the ball bearings themselves, not sealed nor even shielded since they are protected by the new line roller seals. I love it, and I think this new design would last longer than usual since it shuts water out at an earlier point at the roller's ends, instead of letting water in then counting on the bearings' seals to protect them as was previously the case. Also these open bearings should be easier to clean and grease by any user who has some experience in working on reels, which is another means to extend their lives. This new line roller is certainly more friendly to the self-service folks, since it has fewer parts than the older complicated ones and is much easier to disassemble and reassemble for maintenance.

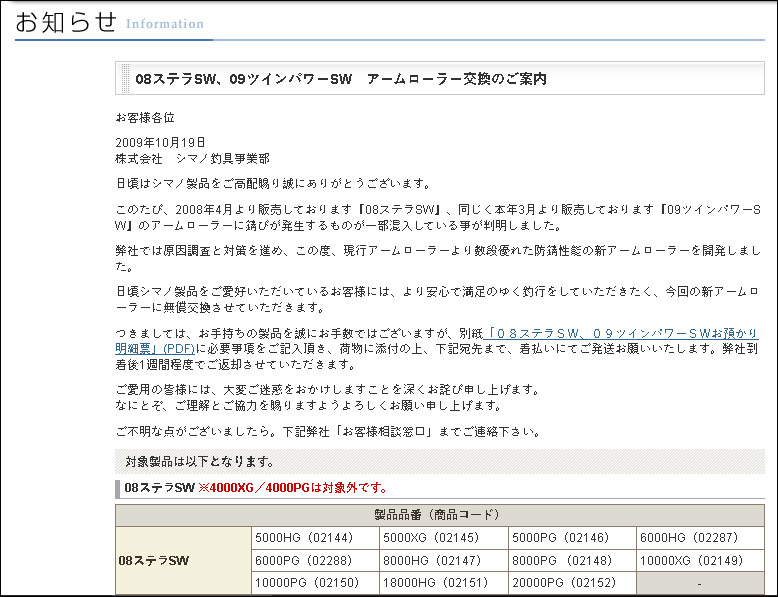

In conclusion, I'm not concerned with the quirks and flaws because none is major or disruptive, plus Shimano is historically known for rectifying issues swiftly whether it's the quick redesign and swap of the melting knobs of the Saragosa F or the full fledged recall of faulty batches of past Stella SW and Twin Power SW as seen in this screenshot. This reel raises some fundamental questions in my head though. What makes a high-end reel? Is it enough to print a reputable model name on it then slap a big price sticker on the box to make it a high-end reel? I certainly reject that, and I would not let anyone redefine what a "high-end reel" is and tell me to shut up and pay because they know better.

It's up to each of us then to decide what makes a high-end reel based on how they personally feel about what it actually offers. Personally, I feel that the 2019 Stella SW has been stripped down and ravaged by cost-cutting measures and lazy dipleated imaginations to the point that is became barely distinguishable from a 2014 Saragosa SW which costs roughly 1/3rd of what the Stella costs Both this 2019 Stella SW and the 2014 Saragosa SW have large drag systems beneath the spool, an externally mounted plastic-housed clutch, both are fully sealed, and both have backup anti-reverse only in the bigger size classes. They're not completely identical, but is this Stella 3 times better than a 2014 Saragosa SW? Not in my book, not even remotely close.

Now let me tell you before it even happens that you might suddenly begin to hear stories that somehow were never told before about the 2014 Saragosa SW supposedly failing on big fish, or see captain "Ahab" from "Smoke up D'Butt" fishing charters swear that his Saragosas exploded in the hands of customers. I explained in a previous article how troll farms operate, and you have only yourselves to blame if you fall for stories that put down the brilliant and proven 2014 Saragosa SW in order for the Ahabs of this world to sell the big buck Stellas they stocked.

Now, new readers might become confused by this next bit, but those who know me would perfectly understand. This new Stella SW is going straight on my golden table of the best offshore reels in current production. That's because I don't see things in simplistic black and white terms, I don't let my personal disappointment impair my judgement, and any potential rubbishing by any company's representatives never makes me lose sight of facts. The facts here remain that this new Stella is an excellent reel that brought fish in without a hitch, it handles harsh conditions like a champ, it's well built, and is an extremely reliable performer. All of which applies to the 2014 Saragosa SW as well. And since that Saragosa itself once flirted with the golden table, it's only normal that this Stella would be on it because it's a bit better than a 2014 Saragosa SW. I just expect more than "a bit better than a Saragosa" when I buy a Stella, that's why I'm gloomy.

Cheers

To support this site and my work, please click here

Alan Hawk

July, 20th, 2019

Updated September, 28th, 2020

REVIEWS BLOG LISTS CONTACT HOME