2005 Van Staal Bailed 250 : The Review

Hello everyone

I've used Van Staal reels since they first appeared, yet never reviewed one because each time I was close to doing it something would change in their design and I'd decide to wait: Drags went from non-sealed to sealed, handle's housing went from smooth to hexagonal, internal counter-weight became external, nut on the handle disappeared, stainless steel shaft became titanium, bankruptcy, two sales, production moved to China, etc. Now I can finally go ahead and do it as things have settled and the design has seemingly reached a stable point where no major changes are to be expected. This review is of the bailed edition, and as we proceed I will point out the differences between it and the bailless edition, so this review is essentially of the two versions of this reel.

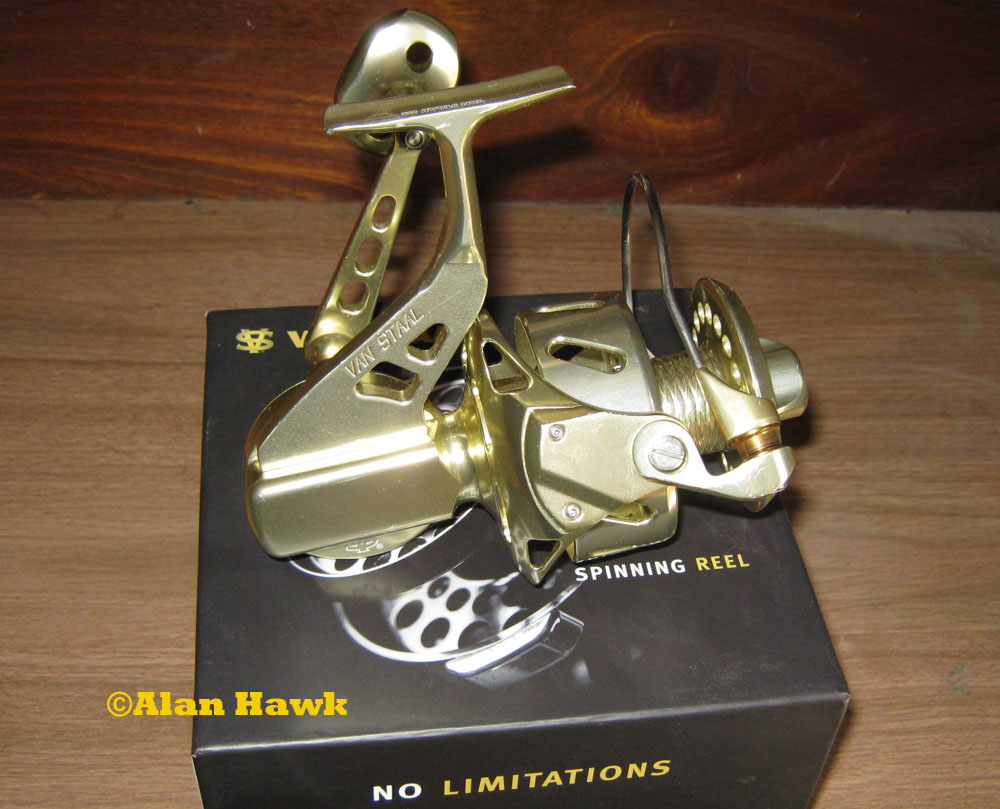

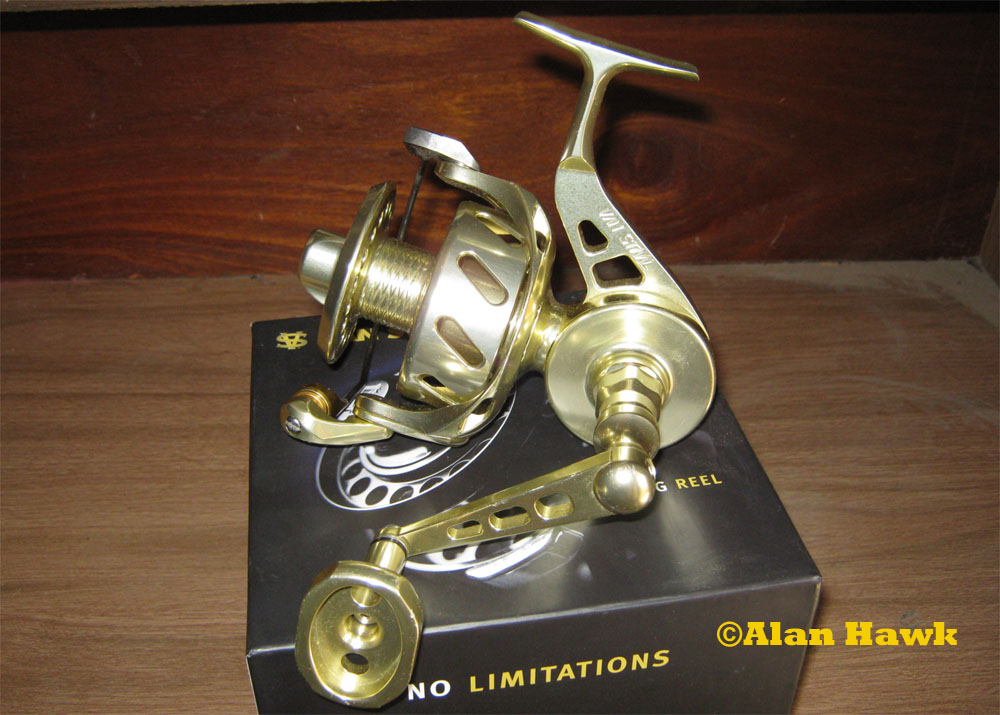

A few photos of the VSB 250, the biggest of the bailed Van Staals

The following is a part of the description of the bailed reels from Van Staal's site

"These reels feature 30 pounds of lock-down drag for the confidence you need when battling the biggest cobia or striper, or wearing down a hard-fighting tuna or marlin".

So not only do they market it as a boat reel, but a boat reel targeting the highest segment of the spinning market where only less than a handful of reels were able prove themselves. That really got me pumped up looking forward to putting it through some action, which I did over 11 outings before it was brought home for the final dissection to see what makes it tick and what makes it not.

The advertised weight is 805 grams (28.4oz), but the actual weight is

770 grams (27.1oz)! My scale is calibrated/tested and is dead accurate, so the reel is actually 35 grams (1.2oz) lighter than the advertised weight. Not sure why is that, but it's much better than finding it to be actually heavier. The advertised line capacity is 600 yards of 50# braid. Stating a capacity using line's supposed strength is nonsense, still those figures sound highly exaggerated. The reel took exactly 230 metres (251 yards) of 0.40mm (0.015") thick braided line. Find the diameter of your favourite line and those figures should let you make a good estimate of capacity.

The spool

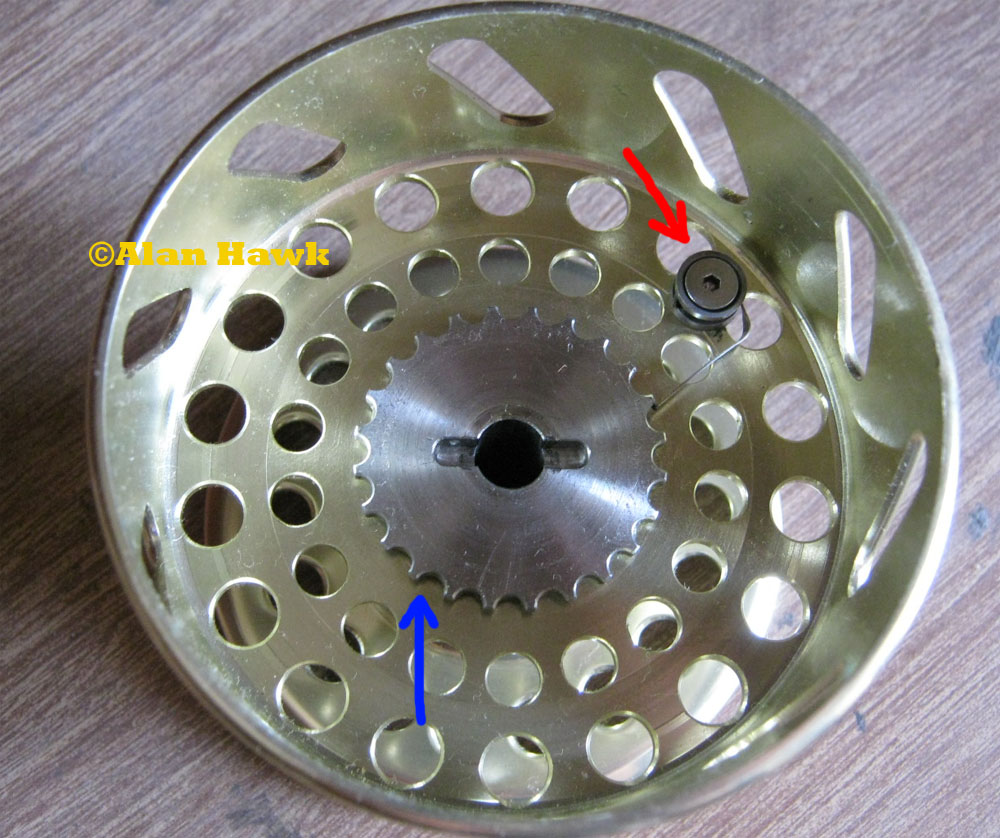

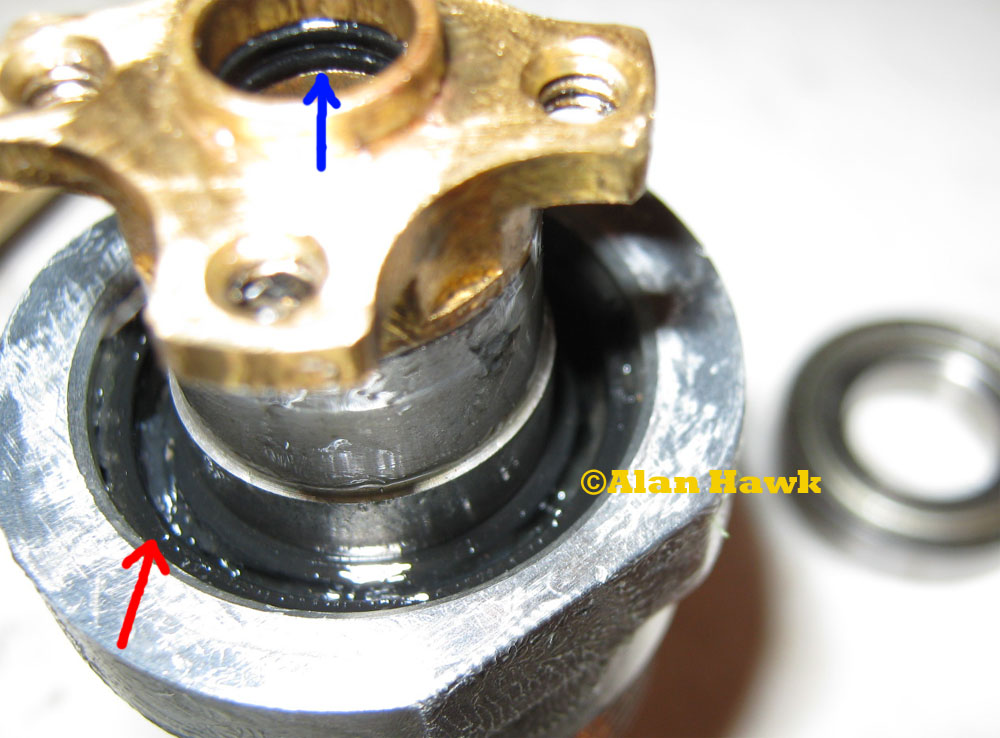

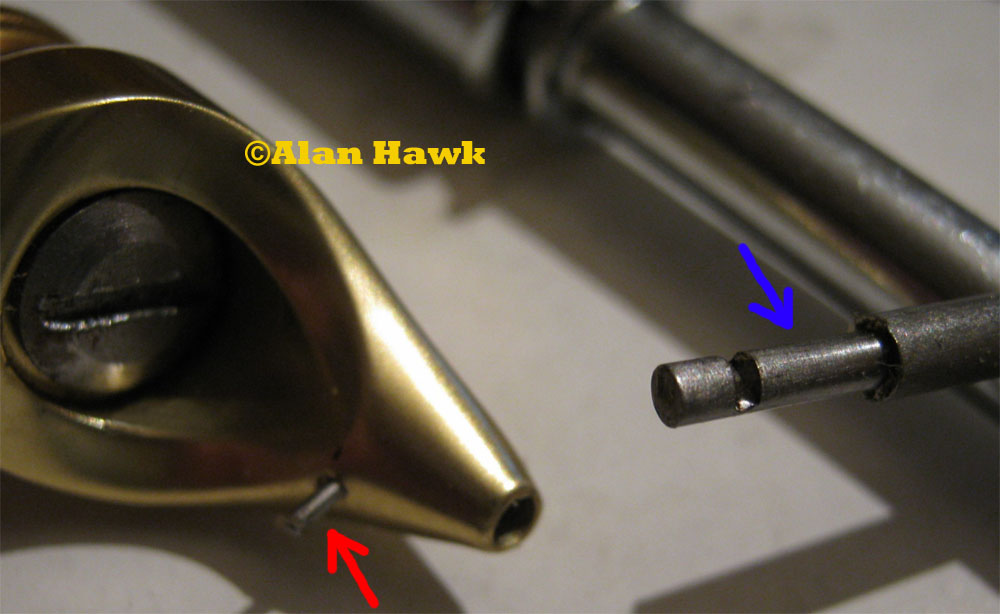

In the photo above the red arrow points the upper drag seal, and the blue arrow points the protruding tip of the spool hub, which is an important feature of the reel that will be explained shortly.

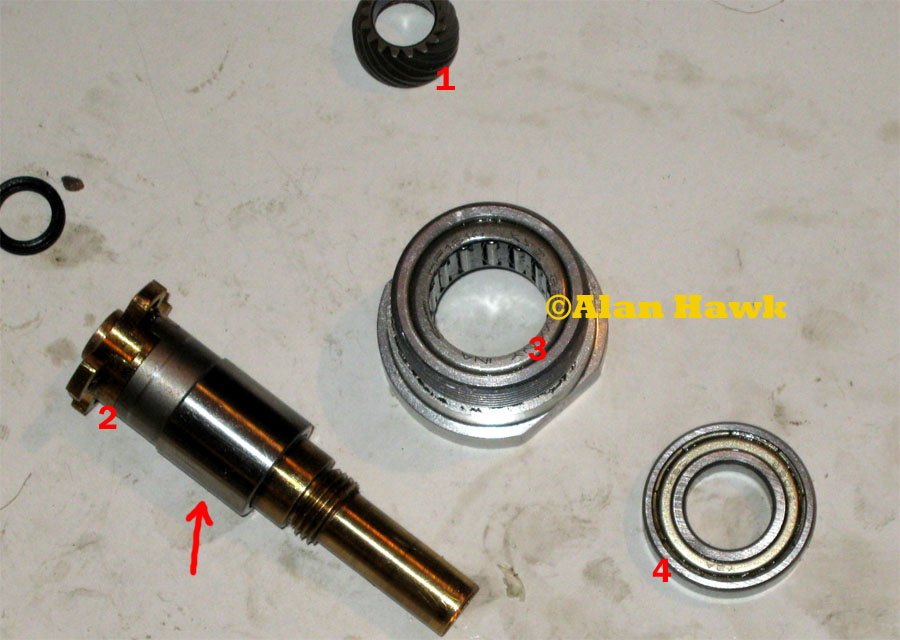

Here is the famous patented sealed drag of the VS, and a big chunk of the review is going to be spent here. #1 is the spool hub, #2 is the retaining clip keeping the entire assembly together, #3 are the upper and lower drag seals, #4 are the two ball bearings the spool rides on, #5 are the four carbon fibre drag washers, and #6 is a pressure disc.

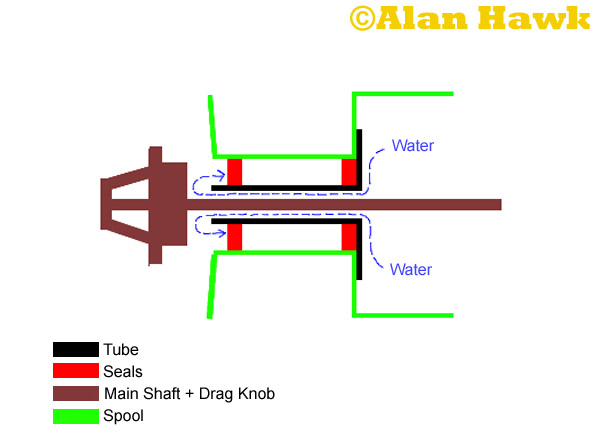

The way this drag is sealed is nothing less than ingenious. When you seal a drag on a spinning reel you need to worry about two different things: The sealing of the drag washers, and the sealing between spool and the main shaft so that water won't sneak underneath the shaft and reach the drag. On the VS they made the spool hub with an elongated tube that goes through the spool and protrudes on the other end. The following is a simplified diagram to help you understand

In this diagram you can see the how drag washers are simply protected by the two seals (red), and then the extended tube of the spool hub (black) goes all the way though the spool and protrudes on the other end, allowing water to freely pass between the spool and the main shaft, and when water exits the tube it would simply drain out of the reel because it can't find its way into the washers' compartment. The drag knob of the VS has no seals, allowing water to drain out freely. Compare that to the sealing of the Saltiga (old and new) where they had to put a hidden seal below the spool hub then double seals on top of it then a large seal around the perimeter of the drag knob, a setup that is complicated, creates added rubber friction to the spool rotation, and more parts to wear out and worry about. Isn't the Van Staal's system super neat?

A closeup on the two Taiwanese made spool seals. These are what's known as "oil seals", which is an advanced type of seal used in industrial applications where higher sealing qualities are required. Oil seals are way superior than regular O rings in terms of sealing performance and longevity.

Due to my itinerary over the past few months I had no access to warm waters, but I was invited by a friend to catch BFT this upcoming May near Cagliari, Italy. I decided that I was going to begin testing the VS anyway, then take it with me to see how it does against big Tuna in May. The biggest and meanest fish I could catch immediately though was Conger eel, and that's what I went after. It's a fish that lives deep around wrecks and is considered one of the most powerful fighters of all fishes pound for pound. These are fished at high drag settings because once they bite they have to be stopped from going back into the wreck and snagging the line, and they should be quickly dragged into open water where there is less risk of snagging and then it becomes all about stamina. I sat the reel at 10kg (22lb) of drag and dropped my whole mackerels, and the action began. Well, I tried to find the most accurate word to describe the drag's performance, and best I could come up with was "underwhelming". A fish would strike, the drag would give line without any felt starting inertia or stickiness of any kind, which is brilliant, but while the spool is mobile the drag would have a lot of hesitation and a non-linear feeling. It's as if while the spool spins the resistance changes and goes up and down in random cycles, and it becomes much worse as the fight goes on and the heat builds up. That non-linear drag performance was a constant, and during the first 5 weeks of fishing the reel I would sometimes crank the drag up when bigger fish strikes and down when smaller fish was on the line, and I always had my electronic scale with me to measure the drag setting every once in a while. A rough chart of the drag performance would show that under about 8kg (17.6lb) of drag it works just fine and the problem virtually disappears as the drag setting goes lower, and higher than that the issue becomes more felt and reaches a point of true disruption at about 12.5kg (27.5lb) of drag pressure.

If you look again at the photo of the drag components (three photos up), which was one of the group of photos taken after 5 weeks of testing, you can see that the drag washers -to my disappointment- were tiny, and bone dry! The centre part of the spool on which the line is wound was made relatively small for increased line capacity, but then the spool hub takes up some of the available space, leaving only a very small space for drag washers. If you compare the size of the washers to the size of the spool bearings in that same photo you can see how they are actually smaller than the bearings! Smaller washers mean more stress is required to achieve a given drag setting, the higher stress will cause strain in the washers, and that is a recipe for non-smooth drag performance and heat generation. Also the lack of grease on the washers isn't good. Dry washers were fine when spinning reels used to be utilised for smaller jobs, but that isn't the best choice when it comes to catching the kind of big fish caught on spinning gear today. As I always said, the main purpose of drag grease is the creation of an even heat distribution for a uniform running and a better a dissipation of that heat, just like the white paste you see on a computer processor right below the heatsink.

I decided to tweak it

This is one of the drag washers after I greased all of them. The maximum drag as I tested in the factory's state was 15.6kg (34.3lb), and after the greasing it fell dramatically to 12.4kg (27.3lb). Of course at that sort of low maximum drag May's Mediterranean BFT was out out of the question, but the drag has become incredibly smooth and handled long runs as if it was a completely different more refined reel.

The drag clicker (red arrow) is loud and durable, yet as simple as it gets for maximum saltwater and corrosion resistance. The design of the spool hub (blue arrow) does not allow adding or removing shims in order to change line lay pattern, which could be annoying

As you can see, my PE6 braid spools in a conical shape with more line being laid on the front half of the spool. I could have used an extra shim or two to correct that, but unfortunately the reel isn't designed to allow shimming.

The handle

The reel's handle is one of my least favourite parts of this reel. It was obviously designed to be perfect for harsh conditions and long submersions in saltwater, which the original VS excels at, but nothing was changed here to make it more suited to boat use. The handle's knob is plainly painful if you're dropping a 250g jig and cranking it up for a few hours, and the pain becomes torturous if there is even a 20lb fish at the end of the line. ZeeBaas put a ball knob on their bailed reels for boat use, and kudos to them for that. Anyway, in the above photo #1 is the stem, #2 is the knob, #3 a washer that goes between the knob and the stem, #4 is the knob's spindle, and #5 is the retaining nut. There are no bearings here so the reel could pretty much be stored at the bottom of the sea between seasons and nothing would happen to it :o

Where the knob meets the stem the finish got damaged with use. Obviously the metal washer sticks to the knob and rubs against the stem. I haven't seen that on Van Staal reels that were used strictly to catch bass from the beach, so obviously this is something related to handling larger fish and heavier lures at depths. A synthetic washer would work better here.

Being quite fussy about little details, I caught those metal shavings inside the head of the knob's spindle shown two photos above. These were created during the forming of the hexagonal housing of the Allen wrench and were left there. Of course it has no effect whatsoever on the workings of the reel, but just wanted to point it out as the only manufacturing imperfection I found in this otherwise beautifully made and finished reel. Of course design flaws are one thing, and manufacturing imperfections are a completely different thing. Reels are not Swiss watches or English bespoke guns, so naturally they will have a lot of imperfections that range from moulding bulges to machining shavings to spotty finish to dripping paint to rough casting marks, etc. The fact that I found only a single manufacturing imperfection in the VS speaks of the superb quality of making considering that the only reel I have seen that has no imperfections was the Stella series. The VS is a living proof that at this time and age a Chinese factory can produce a product of the highest standards if proper supervision and quality control exist.

This is the main reason I'm not a fan of the handle. The above photo shows how the female threads were cut directly into the aluminium handle (red arrow), and those threads receive the solid stainless steel male threads of the gear. In all other top boat reels male and female threads are both stainless steel, whether the female was the drive gear's axle or a stainless steel tube embedded into the aluminium handle. Of course I would have applauded the Van Staal's arrangement as a cost/weight saving measure had it had no negative effect on the reel, but unfortunately it does: I could tell that with repeated use, the position where the handle stops -when it's screwed into the reel- kept moving forward. If you don't understand what that means, imagine having a slot head screw that was screwed into an object with the slot perfectly vertical, and after you unscrew it and screw it again you find that the slot is not vertical anymore indicating that the screw stops further than it originally did. I figured that it was happening through a little mark I made on the male threads of the gear to zero its position each time, then attaching the handle and recording where it first stops under no pressure at all. With time and use I could see that the stopping spot kept moving forward by very little distances, indicating that metal creep was happening in the threads, and I have no doubt it was the weaker threads in the handle being sacrificial. Will that lead to failure? Nope. But it's just something that isn't supposed to be happening, and again shows that the reel could have used a few updates before it was presented as a heavy duty boat reel.

Underneath the spool, four Allen screws secure the rotor to the reel's body. The thickness of the main shaft is obvious in this photo. With a diameter of 7.2 mm (0.28") this shaft is among the thickest ever used on a spinning reel. It's made of titanium and is unrealistically lightweight when held in one's hand!

The rotor

The rotor of the bailed VS features supporting arches similar to what Daiwa later introduced on its first tier Zaion rotor found on the likes of the Certate and Saltiga. Daiwa needed arches to reinforce that plastic rotor, but on the VS it's done on a solid one-piece aluminium rotor which makes it very strong while weighing less than beefier rotors found on some other reels. Those arches redistribute the forces over a larger area and reduce the flexing of the rotor arm under heavy load. Actually I'd say that the rotor arm of the VS bends less than the rotor of a Stella SW does under similar load.

Another look

Full marks for this powerful and aesthetically pleasing rotor.

Back to the body

This is the rotor's mount, and the photo pretty much sums the sealing of the front portion: The red arrow points the large oil seal keeping water out of the pinion assembly, and the blue arrow points the quad seal that protects the main shaft.

The quad seal out. Don't ask me how does it fit inside that tube. It just does

What is a quad seal?

This is a cross section of the quad seal. It has two sealing surfaces on each side, doubling the sealing efficiency of regular O rings. We refer to it as "X ring" in engineering applications because of the way its cross section looks.

The above photos is a closeup on the quad seal next to the pinion/clutch unit unscrewed from the reel.

To disassemble this unit the pinion needs to be unscrewed. This requires a special tool that VS service centres have, but I just cleaned it thoroughly to get a good grip, then wrapped a piece of soft rubber around it until a good sized rubber mountain was formed on top of it, then unscrewed it by hand.

The unit's components

#1 is the stainless steel pinion, #2 is the rotor/pinion mount with the clutch sleeve fitted (red arrow), #3 is the anti-reverse clutch, and #4 is the huge ball bearing of the pinion.

Closeup on the anti-reverse clutch

It has 16 brake cylinders, each cylinder is powered by a sheet metal spring (red arrows). This clutch is of an incredible construction quality and is built for durability. The metal springs will provide a very long service life, and the big number of cylinders eliminate the slightest bit of play. Although those many contact points make it feel tighter than usual to spin the sleeve inside.

Origin of this quality clutch

Hergestellt in Deutschland!

It's important to note here that for the bailed version of the reel, Van Staal made a dramatic change to the anti-reverse. In the bailless version there is a small anti-reverse clutch that works on the shaft of the drive gear, and there is no anti-reverse on the pinion. In that older setup when a fish pulls the line, the pinion is free to spin back and is only stopped by the teeth of the drive gear because the drive gear is the one that has the clutch. Putting that sort of stress on the teeth of both gears isn't mechanically sound no matter how good the gear is, and it also leaves an annoying amount of play in the rotor because nothing brakes the pinion. An anti-reverse that works on the drive gear is an obsolete design that makers began to make away with around mid-1970s. Bass and most beach fishes won't harm that older design of the bailless VS, but big pelagic fish definitely would. This is not theoretical talk. I receive a large number of emails daily with questions and feedback, and over the past year I heard from 4 different people who used the bailless VS for heavy jigging and had all sorts of issues with them. One of those reels was sent to me and I was appalled by the deformation of the drive gear teeth and the small clutch on the handle. For the bailed boat VS though they wisely got rid of that drive gear clutch and opted for this larger clutch that works on the pinion. Besides strength and eliminating stress on the gears, changing the location of the anti-reverse clutch makes the bailed VS much easier to service now you don't have to worry about a lock down if the drive gear wasn't correctly aligned with the traverse guide as is the case with the bailless version.

Moving to the gearbox

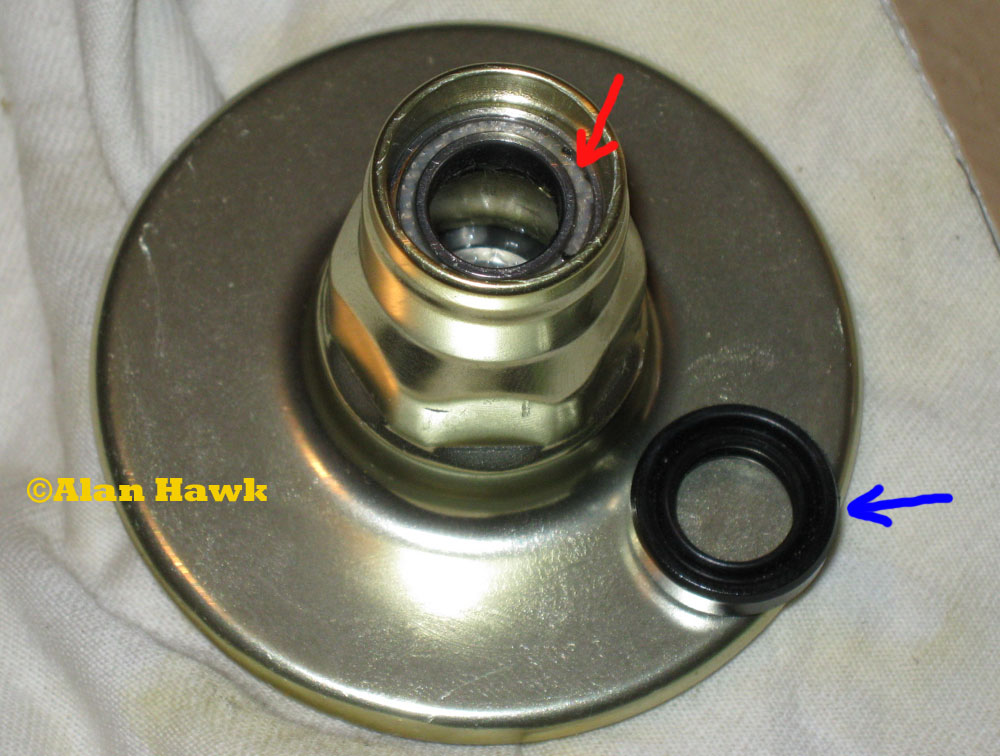

The side cover unscrewed from the reel, and you can see one of the two drive gear bearings (red arrow) cleaned of the old grease, and the O ring seal of the side cover is also visible (blue arrow).

And in the above photo you can see the second bearing of the drive gear (red arrow), and another beefy oil seal (blue arrow) that keeps water out where the handle meets the body. I removed it to expose the bearing.

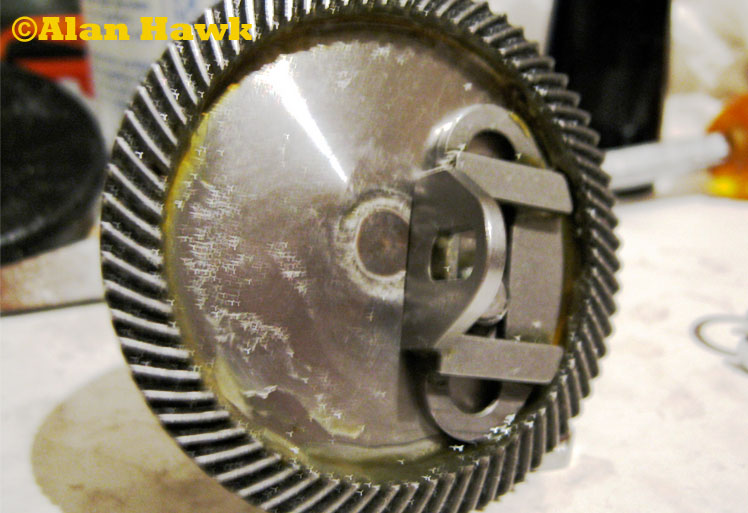

Here is the drive gear. It's one of the biggest drive gears I've seen in a spinning reel. I can probably think of only two or three spinning reels that have bigger gears, notably the classic Intrepid Surfcast which I'm planning to review one day. A bigger gear delivers more torque to the pinion safely due to larger meshing surface, and in the Van Staal's case this meshing surface is greater than that of the gears of the current generations of Stellas, Saltigas, TwinSpins, and Penn TRQs. But that's not the end of the story. We will note this as "Fact #1" and we'll proceed.

Closeups

The teeth are not exactly what I'd call heavy gauge, but after a lot of use they show hardly any wear. I have a good track record in predicting the longevity of the gearing of new reels, but the VS has been there for ages and it's not a prediction to say that the gears will easily serve for a couple of decades with proper care.

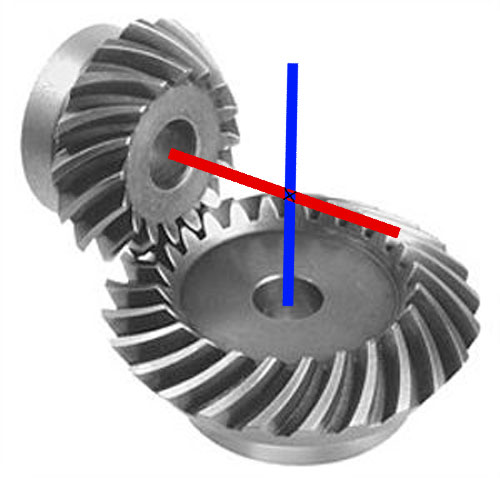

The gearing of the VS is what's called Bevel gearing. In this setup the axes of both gears theoretically intersect. The following diagram illustrates Bevel gearing

In almost all reels made today though a Hypoid gear is used, in which the pinion is offset by a little distance. Comparing those two types of gearing is simple: The Bevel gearing makes it impossible to extend the main gear's axle to the other side of the reel to make the reel ambidextrous, hence reels using this system such as VS and ZB must be made in left hand and right hand models unlike other reels that can have the handle attached at either side. Also Bevel gearing is less smooth, meaning that it produces more gear noise compared to Hypoid gearing because of the lack of the sliding action of the Hypoid gearing. In the VS the teeth are cut at an angle to make a Spiral Bevel gearing which is smoother than straight cut Bevel, but still the gears are way noisier than any Hypoid geared reel.

The main advantage of Bevel gearing that makes those shortcomings acceptable is that it has greater efficiency than any other gearing type. The word "efficiency" is thrown around much with not enough explanation, so I'll define it in a nutshell: It is a relation between the work you put in and the output work the machine produces. The higher the ratio of [output power / input power] is, the higher the efficiency. Again, we will call this bit of information about the superior efficiency of the VS gear "Fact #2" and move on for now.

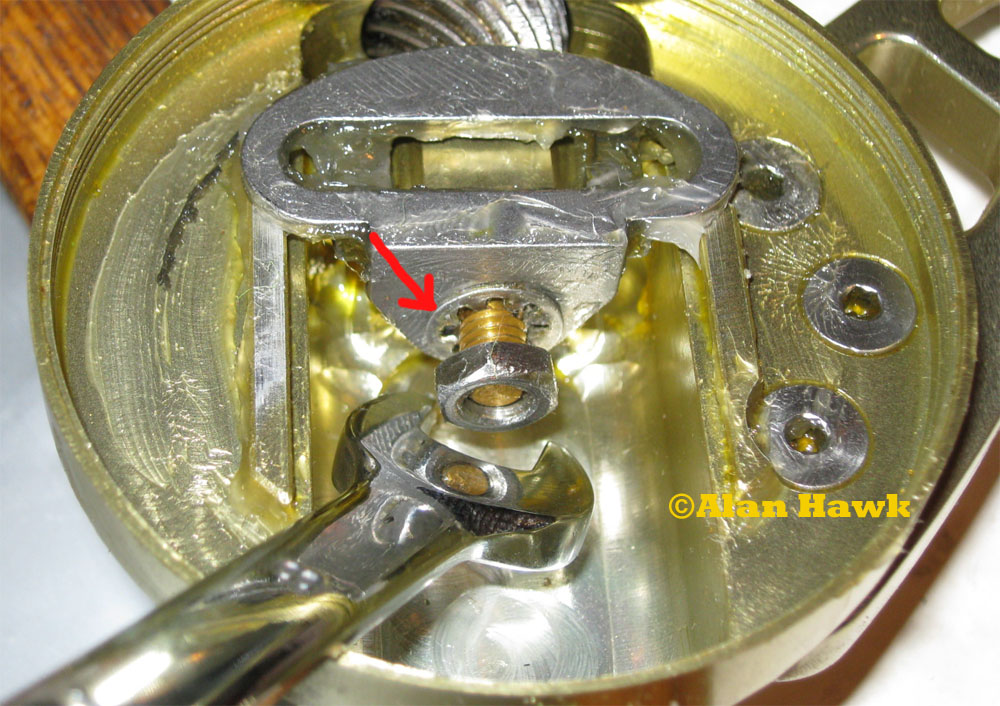

A tiny 8mm spanner is needed to remove the nut securing the main shaft to the traverse guide. The red arrow points the flat nut retainer that keeps the nut from loosening. It does a good job. Never seen this nut loose on any of the many VS reels that I messed around with.

The traverse guide out. Made of stainless steel, and shows virtually zero wear despite many hours of operation. Another part that's made for absolute durability.

I apologise for the shaky quality of the following photo. My hand was covered in grease and the camera must have slipped as I pressed the button.

This is how the traverse guide and drive gear connect. This is a simple connection via a stud in the gear in a setup that I call "direct oscillation", and to elaborate on the effect this has on the reel I will repeat something that I said in response to a question by one of the members of SOL, a site where VS reels are most relevant. He was wondering why is it that using a smaller reel of another brand he was constantly casting further than his friend who was using a Van Staal 200, despite the fact that the friend using the VS was a better caster. The following is my reply, and you can skip it if you have already read that post.

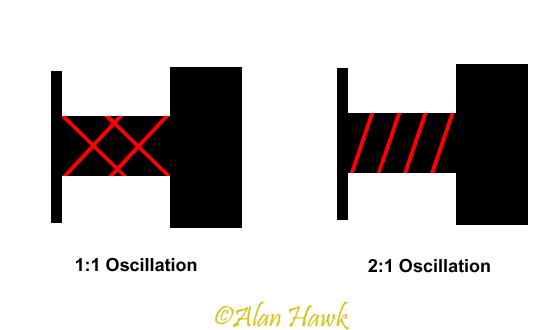

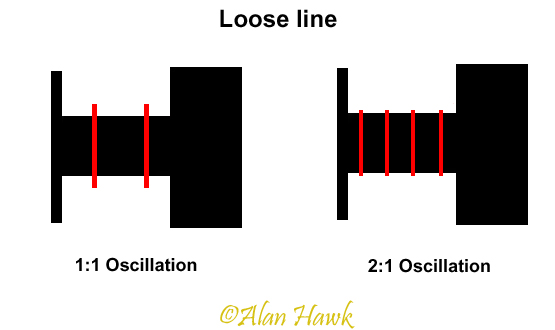

The variable with the biggest effect on casting distance, and by a good margin, is the line lay on the spool. I made a little diagram explaining why the VS and ZB don't cast as far as other reels. In order to understand the diagram, keep in mind that ZB and VS have a direct oscillation. Meaning that for every 1 full turn of the handle the spool completes 1 full cycle up and down. I will call this 1:1 oscillation. Other reels have independent oscillation mechanisms of one form or another, and for every 2 full turns of the handle the spool roughly completes 1 cycle up and down. I will call this 2:1 oscillation. For the sake of simplicity, we will assume that both reels have the same spool diameter, and 4:1 gear ratio, which has nothing to do with the oscillation ratio.

On the left side of the following diagram you can see how the line lays on a 1:1 oscillation reel (VS and ZB) with one full turn of the handle. On the right is how the line lays on a 2:1 oscillation reel with one full turn of the handle.

The above image should get you to understand. On the left side, one handle turn creates two layers of line, one on top of the other, while on the right side it's only 1 layer for one turn of the handle. That means that for the same amount of line to peel off both spools during a cast, twice as many layers of line will leave a 1:1 spool compared to a 2:1 spool. "More layers" means more friction between line and spool lip as the level of line on the spool sinks quicker than that of a reel that peels off half as many layers for the same length of line. Also if you look at the above image again, the line on the left spool will change direction twice as many times while leaving the spool compared to an equal length of line leaving the spool on the right.

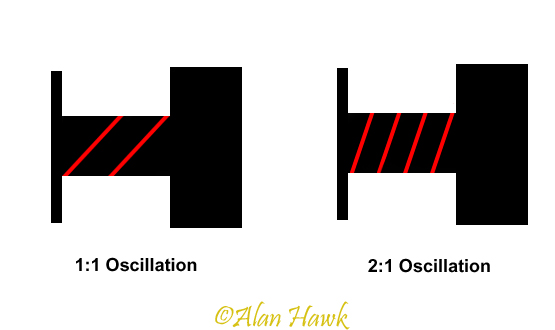

Now forget the ratios, and just examine the angle of the line on both spools in the following diagram. Left is 1:1 oscillation, right 2:1 oscillation

As you cast and coils of line peel off, each coil will pull on the ones beneath it creating some sort of looseness in them. Because of the different angles of the lay on both spools, the loose coils on a 1:1 spool will be bigger than those on a 2:1 spool as shown in the following -exaggerated- diagram

Bigger loose coils create more friction as line slaps itself, and creates a bigger chance of birds nest.

This was the end of my answer, and we can summarise that while the direct oscillation system of the VS is durable and saves weight, the way it lays line puts the reel at a major disadvantage in terms of casting distance and line management when compared to other reels that have modern oscillation arrangements.

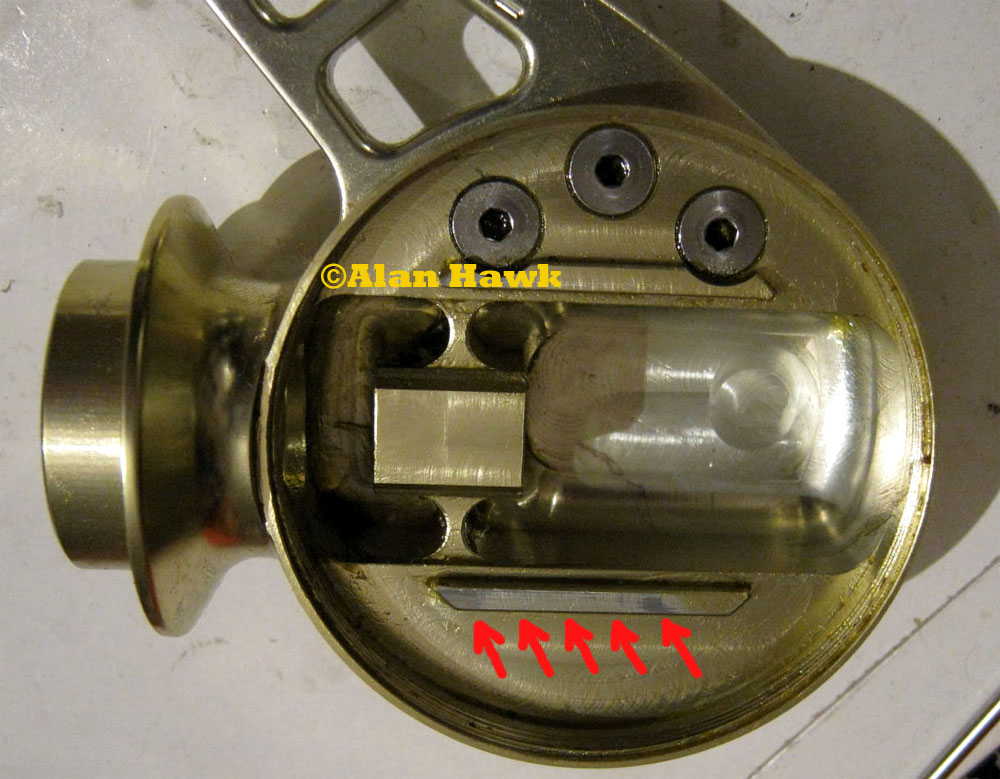

The body of the reel

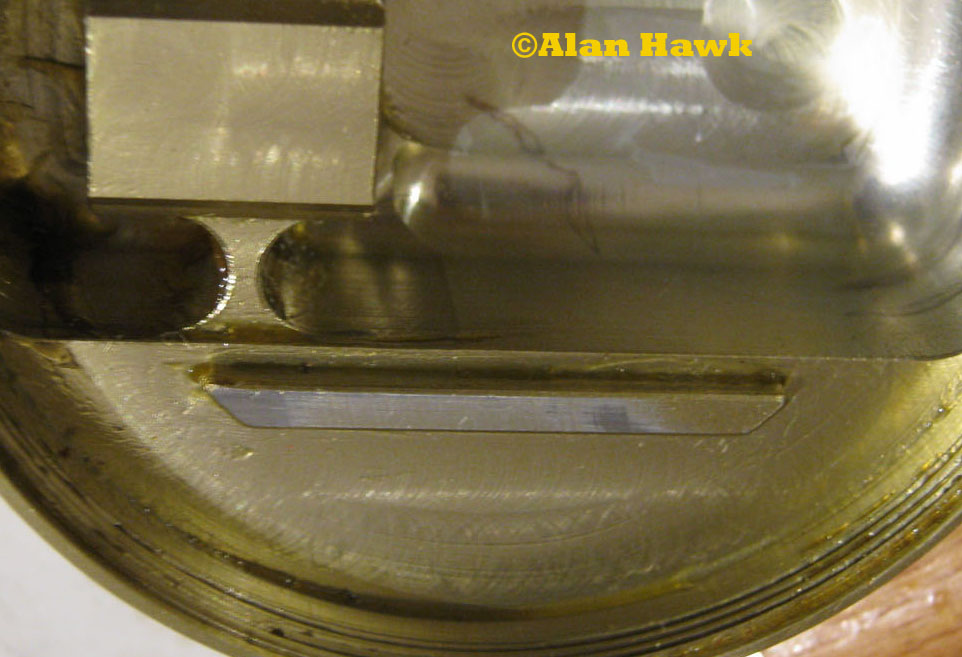

The arrows in the above photo point to bare areas of the rails on which the oscillation guide slides back and forth. Using the reel for heavier boat work caused the guide to rub against the rail hard enough to remove the finish and leave the metal bare as you can see. When you run your finger on those bare areas you can feel that the guide sanded off the rails and left them rough and lower in height.

A closer look at the rail and the damage inflicted on it by the traverse guide. Not only that, but also if you look at the photo of the drive gear 12 photos up, you can spot this:

The blue arrows point to rough rubbing marks around the centre shaft of the gear created by the traverse guide as it struggled to move under load.

Earlier in the review we discussed how the bigger drive gear of the VS transmits torque to the pinion safely, and labelled it "Fact #1". Then later on, we discussed efficiency and how the Bevel gearing of the VS is more efficient than other types, and we labelled it "Fact #2". Those two facts were supposed to make the Van Staal an unparalleled beast of cranking power. But basics of mechanics say that output power equals input power minus power losses. Makes sense? The words "power losses" is the key here. The Van Staal's beefed up and incredibly tight seals make the reel exhausting to operate, and extra work is spent to overcome the friction created by those seals. This is a loss of power. Also the friction caused by the traverse guide as it grinds against the rails is another power loss, and the final power loss is that taking place due to the rubbing of the guide against the face of gear as illustrated in the previous two photographs. In practical terms the reel has less pulling power than every other reel of a similar gear ratio. Working a 300g jig at 70-80 metres for 7 hours left me with a piercing pain in my left shoulder for the following two days, and pulling even a medium fish up from any considerable depth took away any fun that there is in the whole concept of fishing. I've met people who fished VS for years and naturally adapted to their tightness, but people who fish boats with effortless spinners such as Stellas and Saltigas will be punished once they try the bailed VS.

As an experiment I took out three of the seals, the pinion's, the handle's, and the quad, then fished it for 2 days. That was something else. The gear noise was even louder and more felt with nothing to dampen and muffle it, but I got to utilise the full power of the free-spinning reel, and I don't think that I've used anything with such a raw pulling power. Even my revered Stella has nothing on the seal-less VS! (I've just coined the word "sealless"!!)

There were no topwater predators around, but for the kicks of it I threw big poppers only to retrieve and feel how the usually challenging flat faced lures cut through water effortlessly. I realise of course that the slow ratio makes it easier than doing it with a speedy popping reels, but my observations on VS are relative to other slow reels that I popped with: Unchallenged superiority. When I put the seals back I wanted to find any way to make it a freer spinning reel, and after a lot of examination and measuring I decided to do some micro internal machining to relief the tightly fitted parts, particularly the fitting of the drive gear to the pinion. At the end, and after using special lubes that I've tried and tested over the years, the reel has become lighter to spin by nearly 25% and without any form of play developing between parts. The 25% is not an estimation, but rather obtained through testing with little weights hung to the handle the same way they test the trigger pull effort of a rifle. Of course that anemic 25% is nothing compared to the full free spinning the reel had when the seals were off, but still I am proud of end result There were no topwater predators around, but for the kicks of it I threw big poppers only to retrieve and feel how the usually challenging flat faced lures cut through water effortlessly. I realise of course that the slow ratio makes it easier than doing it with a speedy popping reels, but my observations on VS are relative to other slow reels that I popped with: Unchallenged superiority. When I put the seals back I wanted to find any way to make it a freer spinning reel, and after a lot of examination and measuring I decided to do some micro internal machining to relief the tightly fitted parts, particularly the fitting of the drive gear to the pinion. At the end, and after using special lubes that I've tried and tested over the years, the reel has become lighter to spin by nearly 25% and without any form of play developing between parts. The 25% is not an estimation, but rather obtained through testing with little weights hung to the handle the same way they test the trigger pull effort of a rifle. Of course that anemic 25% is nothing compared to the full free spinning the reel had when the seals were off, but still I am proud of end result   The bail mechanism is simple and reliable. The red arrow points a synthetic washer for the bail arm to pivot on for smoothness. The bail of the VS is very pleasant to operate and it has that feel of assisted opening, meaning the spring helps you open it more than it helps closing it, which is the opposite of other reels. It's a manual bail by the way, meaning that turning the handle will not close it and you have to close it manually after each cast.

The other side shows the end metal that doubles as a counter weight. A black synthetic washer could be seen inside its joint hole as well.

I like how the end metal is marked with the reel's model.

A closeup on the line roller showing the black spacer on top of the tiny seal (arrow).

The line roller fully disassembled. #1 is the spindle with the O ring seal of the right end, #2 is the seal of the left end, #3 and #4 are spacers, #5 is the retaining screw, #6 is the line roller itself, and #7 is the bail wire slider cap.

In case you were wondering how I took the slider cap off the bail wire, well, it kinda happened by accident. That little retaining pin (red arrow) kept jumping out every few days and I would push it back with the back of my nail and continue fishing, then by the end of the last fishing day I did not push it back so that I could later pull it out and free the bail wire (blue arrow). That thing is most definitely a rare occurrence that you don't need to worry about as I've never seen it or heard of it happening on any other bailed VS. I fixed it by using a slightly thicker pin which I roughed a little and forced down the hole. Not a big deal.

A closeup on the line roller. You can see two tiny ball bearings inside, retained by an eared snap ring. I love that sort of precise detail on such a small scale. All in all this line roller is as waterproof as the rest of the reel is and should need no care for many years.

To sum it all up, VS reels have metamorphosed over many years and slowly ironed out all the kinks that resulted in failures and leaks in the earlier reels, and have become the undisputed kings of surf fishing with nothing left for them to prove on the beaches of the world. The design of the reel though is so inherently surf oriented that adding a bail and redesigning the anti-reverse wasn't enough to make it a "tuna and marlin" reel as VS hoped for. The reel is painfully tight to spin with its beefed up submarine-like sealing that is not needed on a boat, the drag is too tiny to smoothly handle powerful fish making long runs at high settings, high loads force the traverse guide to slice the body adding even more resistance to an already tight reel, and the handle needs a steel insert for the threads and a different knob. Someone out there might not mind all of that and consider this reel a great tuna and marlin tool, and I have nothing but respect for that. It's just that in my book it certainly doesn't make it.

The fact that I don't consider it viable for the largest ocean beasts though does not change the fact that it's a very strong reel made with premium components and to astonishing standards of fit and finish, and that it's still indeed a great offshore reel. Not everyone is on a boat to catch cow tuna. Despite its shortcomings, and compared to what's out there, the Van Staal bailed stands out as one of the best reels made in the world today and this is why it's currently #4 on my list of the finest offshore reels in current production.

The reel reviewed today shares some aspects with the ZeeBaas bailed, but don't draw any conclusions. The ZB bailed is a completely different animal and I shall review an American made one sometime in the not so far future.

I hope you enjoyed this.

Cheers

Was this a good read? Please click here

Alan Hawk

April, 2nd, 2012

|