World Fishing Tackle (WFT) Two Speed Spinning reel

Hello everyone,

This time I'm reviewing a gadget from mainland Europe. I was not sure if you'd like to know about it, but thanks to the interest you showed when I asked last month, here it is.

I need first to say again that this is just an item of curiosity. Read it for the 'gem factor' then move on. Buying it would be unwise because you will not be able to have it serviced or repaired under warranty outside of Germany, and many parts are quite unique making it near impossible to have it serviced without the original parts.

This reel is one of the handful of spinners ever made on a commercial scale that have two different retrieve speeds (two gear ratios). One of the more known such reels was a special edition of the Quick Super from DAM in Germany, introduced 1968. Here is a photo of that DAM reel, and the arrow points the red button that changes the gear ratio

Unlike the reel reviewed today, that Quick reel had a compact body, yet It did not sell well and was discontinued shortly. That was mainly because no one had any use for it. It came in a time when spinning reels were largely considered freshwater or light saltwater tools. No one thought about going after a fish of a considerable size with anything other than a conventional, hence a spinner that changes gear to generate extra pulling power was redundant.

Things have changed since, and spinning reels became more accepted for large pelagic fish to the point that people started catching huge Marlin and +500lb Tuna on big game spinning reels on regular basis. The next step would normally be following the footsteps of conventionals into a two speed spinning reel, and the reel reviewed today is apparently a first shot at that goal. It's designed by a small German company called World Fishing Tackle, or W.F.T, but unfortunately at $225 it had to be made in China.

Some photos of the reel, and the red arrow in the first photo points the button that changes gear ratio

Here is a short video showing it in operation: The first 2 seconds show the reel in the high gear of 4.8:1, then the button is disengaged and it goes to the lower speed of 2.8:1, then at 13 seconds into the video the button is pressed taking it again to 4.8:1, then once more disengaged at 23 seconds bringing it back to 2.8:1 gear transmission

The reel is a mammoth made entirely from metal, and the weight reflects this fact

At 33.7 ounces it is the second heaviest spinning reel in current production worldwide, surpassed only by the 42 ounces TwinSpin 50.

The weight reflects the heavy construction

The cranking arm is machined thick piece of metal similar to those found on big multipliers. This handle is not going to break.

Still on the handle

The knob has a nice touch: A plate with two screws securing the opening to the knob's axle. Not a seal, rather a cover to protect the lubrication inside. The knob is made of cheap looking glossy plastic, but it works fine.

Bail arm with its allen screw. Actually they used allen screws all over the reel in an effort to make it look 'bad ass'!! Not sure if they have achieved that effect or not, but I know these screws made it a pain in the rear to remove the side cover because one screw is cornered in a way that makes it very tedious to remove with a regular curved allen key. The screw in the line roller also has a very shallow head and the allen key kept slipping out of it

On first examination I noticed that the bail arm was quite thin and thought that it would snap easily fighting a big fish at a high drag setting, but it turned out not to be an issue as I'll explain later on.

Text on the spool is quite interesting

"Leadership for Success"......Hmmmm..... Not sure if I have ever seen anything this corny printed on a reel before. Looks like something a third world dictator would say in his first speech after executing the previous leader

Other side of the spool shows capacity

Why is anyone still listing capacity using line's supposed breaking strength? That might have worked 195 thousand years ago when everyone still used mono that had a semi-uniform strength/diameter rate across brands. But with new technologies in both mono and braid, this system should be retired. For example a 0.50mm Maxima Ultragreen mono will break at 25#, while an ultra expensive 0.50mm Stroft GTM breaks at 46#. This is why the only system that makes sense is to list capacity as diameter/length, be it inch/yards, mm/meters, or PE/metres. Anyhow, this reel holds 155 yards (140 metres) of 0.023" (0.60mm) line, and 370 yards (340 metres) of 0.011" (0.30mm) line.

Still at the photo above, I think it's time for me to get out of the closet It's a secret that I have lived with my whole life and never had the courage to utter. Now times have changed and people like me are accepted by society for whom they really are, I think it's time for me to say it..... I HATE LINE CLIPS!! Those nasty little things found on spools and often mentioned proudly on the reels' feature lists as if they have split the atom! These clips belong to toys and those cute pink rod/reel combos bought from Cabela's for $14.99, plastic wrapped to a cardboard that has a drawing of a happy bear fishing while a smiling bee is standing on his nose!! Ok, I know that some high end spinners have those clips and that there is no logical reason for me to hate them this intensely, but it's just a tick that I have and wanted to let out.

Now to the interesting part: How it works

Removing the side cover, I expected to see complicated unique mechanisms unlike any other reel. But the reel's main body was a simple textbook generic reel with design and components found in 98% of spinning reels made today. The main gear is a basic cast zinc alloy, so is the oscillation gear and the traverse cam which is fixed to the shaft via a single screw that would easily become loose.

The pinion is a light brass one with nothing special about it. The photo above shows the rotor's ball bearing (blue arrow), and they had the decency to put a synthetic washer on the fore part of the pinion (red arrow) instead of just letting it rub against the body's material inside the mid hub (red X) as found on many ultra cheapo reels.

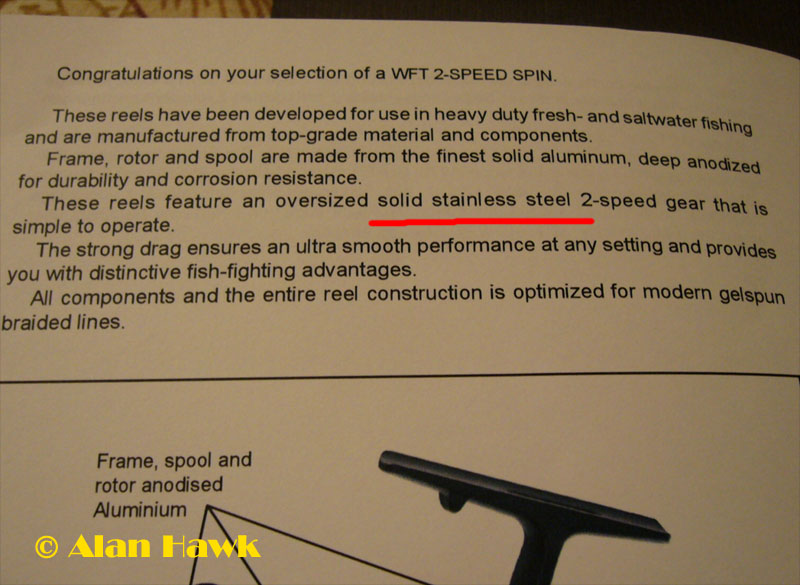

The gears' construction was particularly upsetting because of this

The catalogue, the advertisement, the reel's box, and the specifications on every single site which sells it state that the gear train is stainless steel. Of course I had a perfect ground to return the reel and get a refund, but I decided to keep it anyway because it's a curious reel. Zee Germanz are not known to talk rubbish, but they certainly did this time.

The pinion/anti-reverse assembly

Same generic parts: #1 is a truly low quality one way clutch that has more than average back play. #2 is the clutch sleeve. #3 is an adjusting shim. #4 is a flimsy cover that holds the clutch and does not look as if it can handle the pressure from a big fish. But again, not really a problem as I'll explain later. #5 is the rotor/pinion ball bearing held in place by the rims of two screws (red arrows).

A quick look at the line roller

The attachment of the bail wire to the roller feels solid.

Inside the roller

No ball bearings inside. Just a washer and 2 spacers that were assembled wrongly on the same side of the line roller from the factory

As I said, the reel's main body is pretty standard, but here is the part that makes all the difference

Photographed above is the side cover which contains the bulging gearbox and the speed shifting button. Everything takes place inside this box, then the end result is delivered to that sticking hexagonal shaft (red arrow). This shaft will either spin fast to give the 4.8:1 ratio, or spin slow to give the 2.8:1 ratio. This shaft goes into the female hexagonal tube in the main gear, exactly similar to attaching a hexagonal tube handle to a standard reel such as Emblem Pro or Black Gold. The green X is a small housing for a ball bearing, but we will come to it later.

The other side of the body

You can see a standard screw that secures the hexagonal handle shaft to the main gear, again like any standard reel. Naturally the handle on this reel can only be attached to one side and there is no left hand version. A screw-in cover then protects this opening (red arrow). Need to mention here that this is the second generation of this reel. The first one was faulty and major changes needed to be done and a second generation released quickly. An easy way to tell the second generation from the first is this round cover: In the first generation it was not a screw-in cover, but rather a round plate secured to the reel by an allen screw.

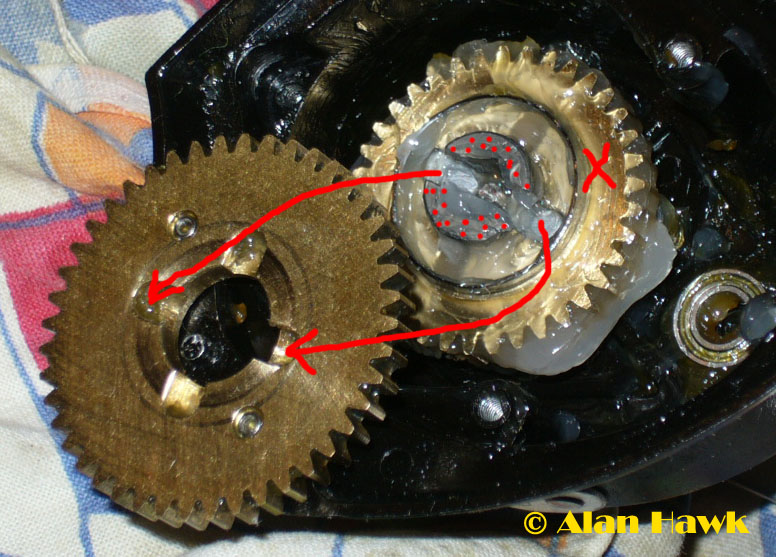

Getting inside the gear box, and I'll try my best to keep it simple

The red arrow points to the plate carrying the hexagonal shaft that transfers the end result speed to the gear as explained earlier. This plate is attached to the yellow bronze gear underneath it. We will call that yellow bronze gear "the fat gear" for easy reference. The blue arrow points to the small zinc alloy gear with two sets of teeth that controls speed. We will call it the "double gear" for easy reference. This small double gear is mounted on two small ball bearings. One underneath it, and the other one fits in the recess I marked with a green X two photos up.

This photo has the key to understanding how the system works

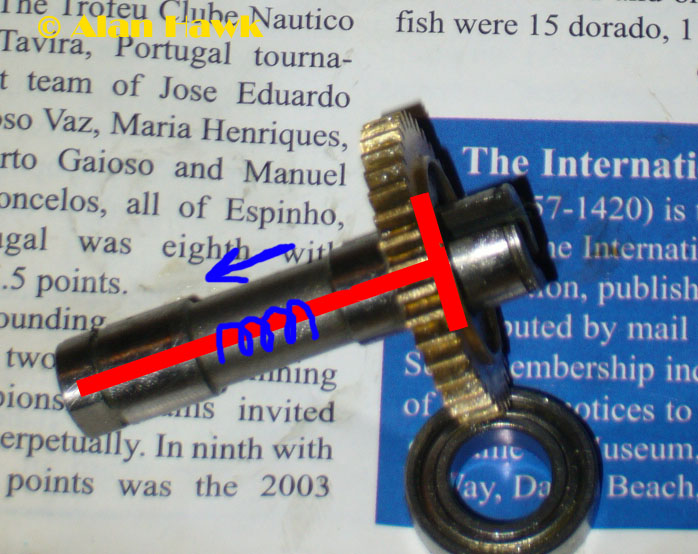

#1 is the back side of the "fat gear". The red arrows point to cross cuts in it. #2 is what we will call "first gear", and the blue arrows point to cross cuts in it too (hard to see because of the grease). The shaft (marked by red Xs) of that "first gear" is not solid. Rather a hollow cylinder of steel, and inside this cylinder there is a spring-loaded T shaped bar. #3 is the lower ball bearing for the small "double gear".

Here is the "first gear" out

I disassembled everything and tried to explain, but it was nearly impossible and required lots of imagination. So I reassembled that gear and drew the T bar in red, and drew the spring in blue. The spring pushes the T bar in the direction of the blue arrow.

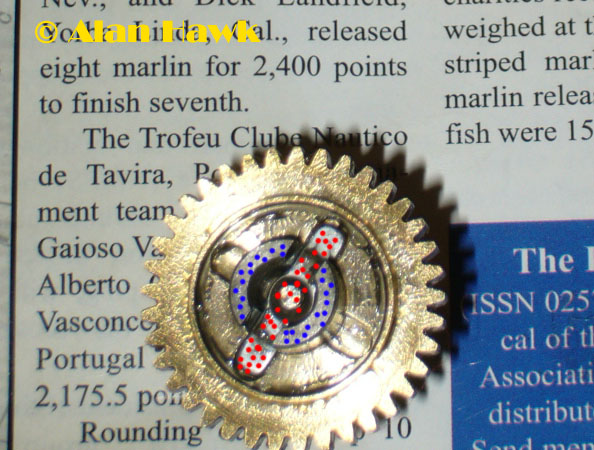

You probably get it now, but here is another view of that first gear from the top for further illustration

I drew red dots on the horizontal part of the T bar, and blue dots on the gear shaft. That shaft (blue dots) is not fixed to the gear, but rather can turn free inside the gear. When the T bar is at its normal position, the spring bushes it back so that the horizontal part of it (red dots) engages 2 of the cross cuts on the "first gear", bonding the shaft to the gear. This means that in this normal position turning the shaft will turn the "first gear". We will call this "Case One", and will leave it here for now.

But what if the T bar was pushed up by the button that changes gear ratio?

When the T bar is pushed up, the horizontal part of the T will engage two of the cross cuts on the back of the "fat gear" as pointed by the arrows. This action will break the bond between the shaft (red dots) and the first gear (marked by X) and create a new bond between that same shaft and the "fat gear". Hence when you turn the shaft, the "first gear" will remain idle, while the "fat gear" will turn. We will call this "Case Two".

In "Case Two" (the fat gear turning), movement will come directly from the handle to the fat gear, and, if you remember the first photo inside the bulging box, the hexagonal shaft is attached to the fat gear, hence the rotor will spin at the direct speed of 4.8:1. Now we are finished describing the high speed.

In "Case One" though, where the handle turns the "first gear", the "double gear" will come to action

In the above photo (Case one), the first gear (hidden underneath the fat gear) will turn with the handle, and accordingly will turn the "double gear" (pointed by red arrow), and that "double gear" is going to transfer the rotation to the "fat gear" at a much lower rate because of its small size, then the fat gear will turn the mounted hexagonal shaft which then spins the rotor at the slow ratio of 2.9:1

Here is a close up of the "double gear"

And that ends the complicated part of this review. Do you get the whole mechanism now? If not, give it another reading and it will all become clear in your mind.

Closer look at the magic button

#1 is the button. When it is in the up position, the reel spins at 2.8:1. When it's pressed to its down position, it goes to 4.8:1. #2 is the release wheel. When turned 2 degrees counter-clockwise (the direction of the red arrow), it releases the button to its up position again changing the reel into the slower retrieve. #3 is the assembly nut. It's screwed down to hold the button mechanism together. That nut is a true manifestation of the masterful Chinese craftsmanship: I noticed that with every cycle of the button, that nut loosens itself a little bit. When I noticed this, I naturally tightened that nut down. But guess what? The threads inside it extend by 1.5 mm more than they should, hence when the nut (3) is securely tightened, the release wheel (2) gets jammed by it and can't move, therefore the button would not stay down

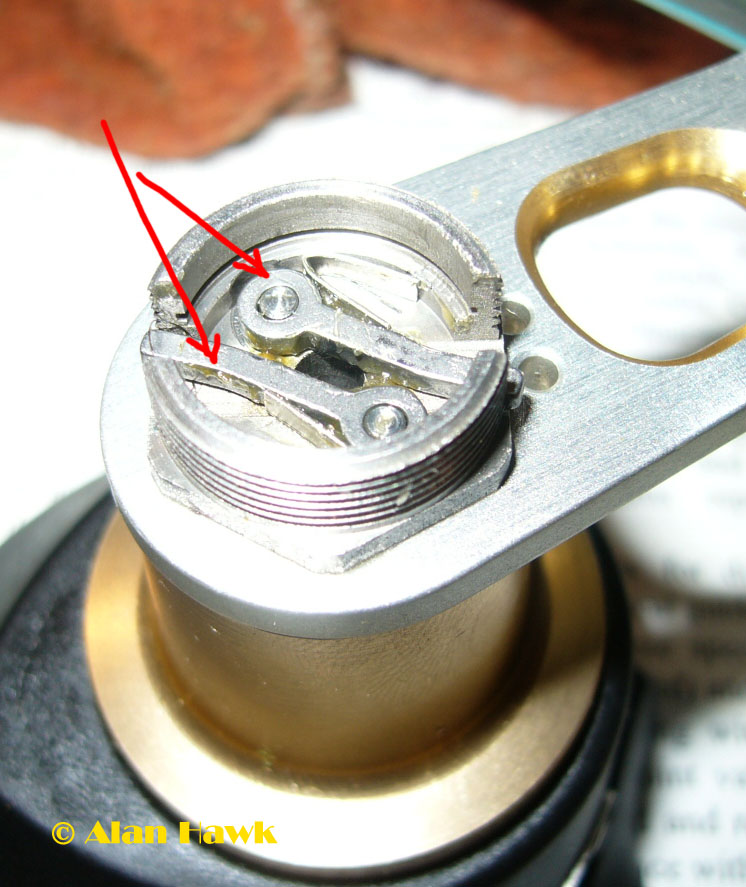

It was an easy fix with some loctite on the threads so that the nut would not move when it's screwed down half way only. But an embarrassing flaw nonetheless. It was an easy fix with some loctite on the threads so that the nut would not move when it's screwed down half way only. But an embarrassing flaw nonetheless.This is what holds the button down when you press it

The red arrows point to the 2 small spring loaded hinged levers, which snap into a recess on the button's axle to keep it down. When the release wheel (not installed in this photo) is turned, it pushes the tips of these two levers away from the recess so that the button could jump back to its up position.

This, too, is quite interesting

There is a second one way anti-reverse clutch in the handle (the main anti reverse clutch is in the pinion/rotor assembly), and there is a story of poor engineering behind it: It seems that they originally wanted to include a mechanical backup anti-reverse in case the one way clutch slips while fighting a fish. This is becoming a standard feature now and could be found on high end Stellas and Saltigas as well as on $80 reels such as Penn Sargus. So, when they designed this dual speed spinner, they included a post to carry an anti-reverse dog (red circle in the following image)

Then they cast teeth on the back of the rotor (pointed by the red arrow in the image below) so that the dog could stop the rotor in case the one way clutch fails

But then they discovered that there is too much play in the handle: In regular reels that has only a drive and a pinion gears, there is a single cause for handle play which is the space between the teeth of the drive gear and the teeth of the pinion. This is a very slight play that is a must for the gears to work efficiently without excessive wear. But this reel has three extra gears and that slight play exists between the teeth of each two gears in contact, therefore the total play of all 5 gears translates into way too much play in the handle. To fix that, they decided to put the second one-way clutch on the handle to cancel any handle play felt by the user, then they realised that this second clutch they were forced to add would act as a backup stop if the main clutch fails or slips, hence they no more needed the mechanical backup stop, and the post and teeth were left unused. Maybe I'll just install a dog and a spring on that post so that I'll have the only triple anti-reverse reel on earth!! Send me your offers gentlemen, starting bid is $50,000 for that unique triple brake gem

The blue arrow in the above photo points to a nice feature: A fake rotor's flat. I could not capture it clearly on camera because of the black colour of this reel, but I will illustrate it using the rotor and fake flat of a Stella SW.

This is Stella SW's rotor

It looks quite innocent when you look at its flat. But in reality you are looking at a thin cover that is not a part of the rotor.

When that cover is removed, this is what you'll see

Red arrows point to the places where considerable amounts of metal were removed from the rotor to reduce weight, then the fake flat was installed to give the rotor's bottom a smooth look and keep dirt away from these cutaways and channels. This trick from the Stella was adapted in the 2 speed spinner reviewed here, with metal removed from the bottom of the rotor to reduce weight. But to the credit of this dual speed reel, the fake flat here is metal, while in the Stella it's plastic as I pointed out in its own review. And in case you were wondering about the hole in the previous photo, it's a bullet hole. Not giving details not to embarrass the guy who sent it to me, but let me use this instance to make a small disclaimer: Don't read my reviews unless you know what a "figure of speech" is. When I say that Stella SW is bullet proof, it does not mean that you can put a 22 hornet through yours then come whinge to me that I mislead you

Finally, moving to the drag. I did say earlier that the not-so-strong bail arm and the flimsy anti-reverse clutch assembly were not really a problem, and this is why:

In order for them to increase the capacity they reduced the diameter of the spool's spindle too much, and accordingly they could only put drag washers of a very small diameter. The end result is an anaemic 10.5 lb of maximum drag! This is not bad for most reels, but for a reel of that size and weight, which happens to have a two speed retrieve for fighting big fish, it is just ridiculous. That low maximum drag is the reason I did not worry about the pathetic bail arm and one way clutch. They can handle that small maximum drag safely, and any extra pressure would just make the spool spin and give line before any real stress could transfer to the reel and harm those weak parts. Still in the above photo, the clicker mechanism (red arrow) is quite intriguing. I love a good complicated clicker and always find it a telling sign of the quality of the reel, but here the clicker is totally out of place: It's very well engineered, reliable, very durable, but the mechanism is so overbuilt I estimate that it alone weighs 1 oz. Not really a smart move when you're building one of the heaviest spinners in the world.

The rest of the drag system

Underneath that clicker mechanism there is one more drag washer of a bigger diameter than the ones in the upper stack. This does not help much because it's still small, and it's made from a hard surface plastic material that hardly has any braking capabilities.

One last image

The drag knob has a round seal (red arrow) to protect the drag from water splashes. Again something that is becoming a standard feature in most spinning reels built today.

In conclusion, the reel is not that brilliant, apart from the double speed gearbox. Some of its faults could be easily fixed with some loctite or a little tweaking, but some of the problems need a thorough re-engineering. I would make a longer cranking arm because lots of potential winding power is lost because of this short arm, I would remove the unused post of the cancelled backup anti reverse and the unused teeth from the back of the rotor, and I'd replace that heavy drag clicker system with a simple bolted clicker tongue and a metal gear on the shaft. I would also sacrifice some line capacity for a thicker spool spindle so that larger drag washers could be installed along with stronger stress-bearing parts, and finally I'd remove any references to stainless steel gears because there aren't any inside and this is just absurd.

This reel is better looked at as a concept rather than a step in a new direction. Hopefully one of the big two will pick the idea up and build a real reel on it because the concept is promising. I did not go after anything challenging with it because of the limited drag, but I did manage to catch good size red snapper, Goliath groupies, and spangled emperors on it. And even though there was no real need for that, I often changed gears to slow retrieve once I was hooked then mightily enjoyed skull dragging the fish with that amazing torque the slow ratio generates. With all its problems, at low gear this reel does produce the biggest pulling power of any spinning reel that I have used.

Hope you enjoyed reading this, and hopefully before too long I'll post something more mainstream like Daiwa Catalina, Saltist, or the Penn Torque.

Cheers

Was this a good read? Please click here

Alan Hawk

October, 14th, 2009

|