2008 Shimano Stella SW : The Review

Hello again

Today we move up to the very high end of the spinning market, an area reserved for an exclusive class of reels that usually cost 4 or 5 times as much as standard mid range reels. Current examples of these would be the Daiwa Saltiga, the Accurate TwinSpin, and the reel reviewed today, the Shimano Stella SW.

Before I commence, let me point out that this isn't a magazine style review. I tend to get technical, delve into history, make comparisons, and often include trip reports too. Bear with me and I promise it's not going to be too boring or complicated. Another thing; I keep getting messages from people who want me to repair or service their reels, so let me remind everyone that I do not do repairs or service tackle. I'm just a big fishing & tackle junkie who likes to share his findings, not at all a pro.

Of course everyone knows what a Stella is. Most fishermen consider it the "Rolls Royce" of spinning reels, thanks to a great reputation built over many years, although I have to say that the reels have not always lived up to that reputation. Most of the Western world first heard of the Stella in 1998, when what's known internationally as the "Stella F" made its way to our shores. The name was actually 5 years old at that point since the first Stella appeared in Japan in 1993 as a small freshwater series sized 1000 to 4000, then it expanded to include large saltwater reels up to 10000 size in 1995. In the sizing system they used back then 10000 was a full size, not a medium reel. Here is a photo of a 6000 reel from these first saltwater Stellas

Since the beginning, the Stella was made as a fully metal reel equipped with the latest technology available at the time. It initially didn't come with specific freshwater and saltwater designations, but rather it was simply "Stella" and the use of each individual reel was largely determined by its size. In 2001 though that changed when the reels were split into the "Stella SW" series for saltwater fishing (FA in export markets), and both "Stella FW" and "Stella AR" for freshwater work.

That 2001 Stella SW (FA) came in the same year as Daiwa's Saltiga Z. That Daiwa had some revolutionary features well ahead of its time such as full sealing of the body/drag/line roller, a 3D computer designed and cut drive gear made of C6191 wrought alloy, and a one-piece bail wire just to name a few.

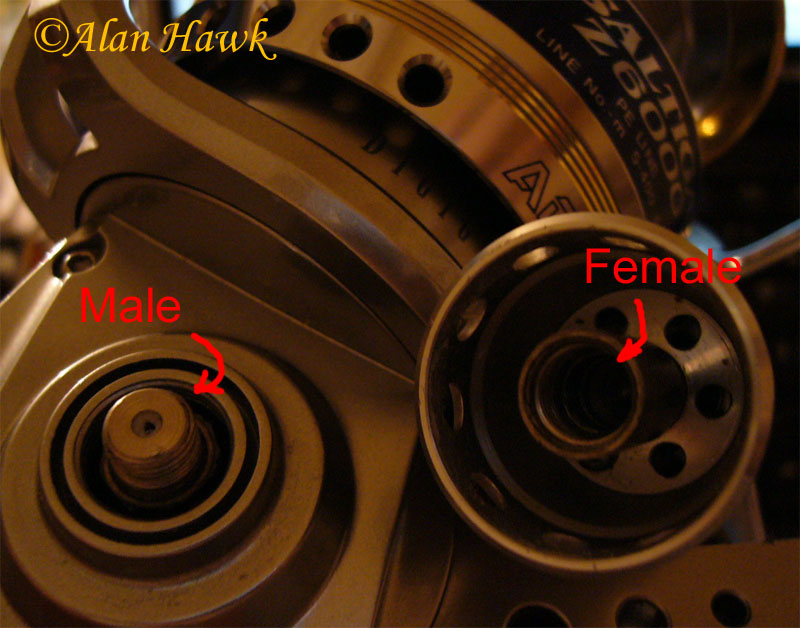

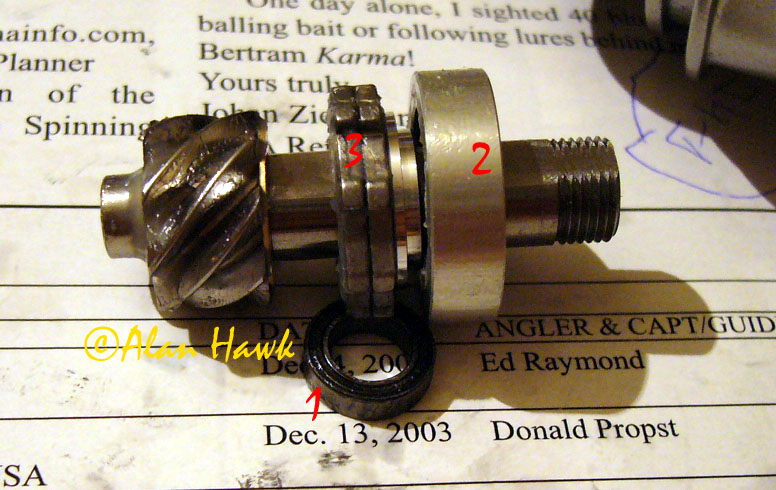

The 2001 Saltiga Z also had a "male" drive gear shaft while the "female" threads were placed in the handle as seen in the following photo

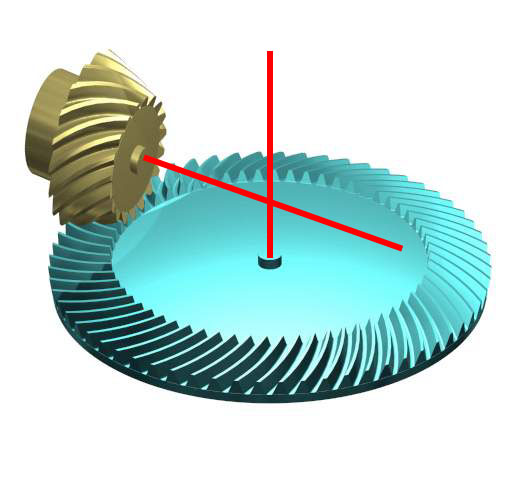

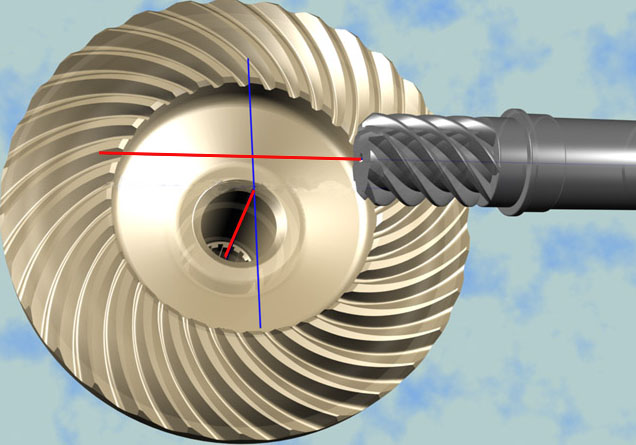

Naturally, this male gear shaft of the Saltiga Z was thinner than the female gear shafts found in most other reels including the 2001 Stella SW, which allowed that Saltiga's gear to have minimal offset to the pinion for higher transmission efficiency. Let me explain this quickly; the highest efficiency is usually achieved by a gearing arrangement known as "bevel" gears, in which the axis of the pinion intersects with the axis of the drive gear as in the following illustration

This highly efficient arrangement is found in spinning reels such as the classic Mitchell 488, Penn 720/722, and Van Staal surf models. These reels though aren't ambidextrous because of this gearing. The drive gear's shaft can't extend to reach the other side of the body because the spool's main shaft would be in its way. To create ambidextrous reels this highly efficient gearing had to go, and in its place another gearing system called "hypoid" was employed. In this hypoid gearing the drive gear is slightly offset as in the following illustration

This way the shaft of the drive gear can extend to the other side without being blocked by the spool's main shaft, therefore making ambidextrous winding possible. The efficiency of the hypoid gearing though is less than that of the bevel system, a sacrifice that was accepted for the sake of the convenience of left/right winding. The creators of the 2001 Saltiga Z wanted to minimise this sacrifice, and by employing a thin male gear shaft they could bring the drive gear closer to the pinion, further reducing gear offset and squeezing as much efficiency as possible from the hyoid arrangement. For the fisherman this translates to more cranking power, something that you'd notice if you've used these Saltiga Z reels long enough.

As great as that Daiwa is, its drag system wasn't as good as that of the 2001 Stella SW. The factory drag washers of that Saltiga Z had the tendency to stick at high drag settings, causing a momentary spike in pressure when the spool began spinning during a fight, leading to instances of breakage in the stem and at least one documented case of bail arm breakage

Drag spike, or "starting inertia" as it's sometimes called, is a fact of physics. Newton says that a static body tends to stay static, and a moving body tends to keep moving. Therefore a static spool set at 40# of drag pressure will not move at 40# of pull, but rather would need a higher amount of force to overcome its static inertia and get it moving, and once mobile the spool will only need the original 40# of force to keep going. The difference between that initial force needed to overcome static inertia and the force needed to keep the spool going is what makes one drag better than another. The smaller that extra force is the better the drag, and with the sticky factory washers of the Saltiga Z there was no doubt that the 2001 Stella had a superior drag system. Many anglers would resort to replacing these sticky factory washers with after-market "Carbontex" washers, and the upgraded Saltiga Z would then come out on top as an overall superior reel to the 2001 Stella SW. I explained all of this so you'd know what sort of competition is waiting for Shimano's newest weapon; the 2008 Stella SW.

In Japan the new 2008 SW comes in 13 models offering different combinations of sizes and gear ratios. The reels come in two versions, one for the Japanese Domestic Market (JDM), and another version for exportation to international markets. The JDM reels are named SWxxxxxPG/HG/XG, where PG is Power Gear (low gear ratio), HG is High Gear (high gear ratio), and XG is Extreme Gear or Extra High Gear (highest gear ratio). The export version is named xxxxxSW with no gear designation except for a single model called 8000SW PG which is a low gear ratio version of the regular 8000SW. For the US only 6 of the 13 models are available. The smallest size available in the US is the 5000, then there are the mid-sized 8000 and 10000 which have the same body size but with different spool capacities, and finally the full-size category which includes the high gear ratio 18000 and the low gear ratio 20000, both having the same body size only with a larger capacity spool on the 20000.

It is important to mention that the JDM and export versions have some cosmetic differences and slight variations in the colour scheme, but they are built to the same standards and are of the same quality. There have been rumours on the web that the export version is made of inferior materials and cheaper components, but I disassembled both the JDM and export versions and can tell you that these rumors are incorrect. Reels often go through slight changes in design during their production lives, and sometimes someone would spot a small gear that has a coating in one reel then would see that same gear without the coating in another and assume that they are built to different standards, when in reality one reel is simply earlier than the other having been made before the design was altered.

A quick list of the main cosmetic differences would include the handle colour which is grey in JDM and yellow in export reels, the bag that comes with the reels is different, the spool of the JDM has the printed text "ARC spool" and the export doesn't, the body of the JDM has the text "Aero Wrap" while the export reel says "Aero Wrap II" instead(identical, just marketing), and the JDM has a serial number in the foot for domestic service purposes while the export reel doesn't.

The 18000 and 20000 have what Shimano calls "hyper twin disk drag" where large drag washers sit beneath the spool in addition to the smaller drag washers in the stack at the top of the spool. In sizes 5000 to 10000 the main drag unit is in the stack at the top of the spool with a secondary drag washer beneath the spool, while the 4000 size only has drag washers in the top stack, The drag washers of all sizes are made of woven carbon fibres, except the 4000 size which has felt drag washers. This 4000 size is not available in the US.

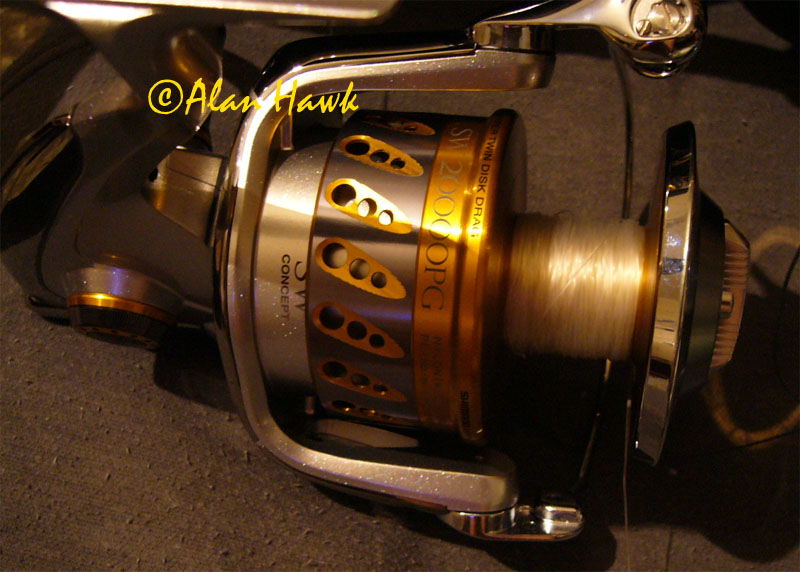

The JDM 20000 featured in this review was bought from Japan for $1200, a record amount for me since the most expensive spinning reel I've bought prior was a $900 Accurate TwinSpin. The reel is gorgeous, pure and simple. Actually it's so pretty that when I first opened the box I didn't have the heart to remove the hologram strip from the spool and load it with line, so I just photographed it and hid it in the closet for a week or so! Here is a photoshoot session and you be the judge!

Spooling it straight with braid could cause line slippage since the spool has a low-friction slippery finish. JDM reels come with stickers to secure the braid to the spool, but I'd rather do something else...

I put a bit of mono first for a tight grip on the spool, then connect the braid to the mono and continue filling it. Not the cleanest method but in my mind the most secure.

Filling it up one immediately notices both the reel's smoothness and its free-spinning. The correct definition of "smoothness" is the fluid feel and absence of felt and heard gear noise during operation, while "free-spinning" means the ease of turning the handle with little resistance. The 2008 Stella SW is very smooth, equal to the Saltiga Z in this regard, but it's more free-spinning than the Saltiga Z which feels tighter to operate due to its heavier sealing.

The new Stella SW is lighter than its predecessor. Much lighter indeed across all sizes. My 20000 weighed 29.62 oz (840 grams) without line, which is about 3 oz (85 grams) lighter than the 2001 Stella SW 20000. The equivalent Saltiga Z 6000 is still lighter at 28.74 oz (815 grams), but the difference isn't that big.

While doing comparative weighing I caught this funny fact...

The handle of the Saltiga Z is actually heavier than that of the new Stella despite the handle of the Stella having chunkier sections and parts. It's in the alloys themselves, the Stella being a newer reel featuring improved alloys.

I first fished it on the surf, and immediately could tell that it casts better than both its predecessor, the 2001 Stella SW, and its main competition the 2001 Saltiga Z. The new hardened reverse-tapered spool lip is mostly responsible for this, sending line out in tight coils with little friction. I could constantly cast 15-20% further than I did with the previous Stella.

Another thing that was pretty useful in beach casting was the powerful rotor cast brake, which is a mechanism that automatically holds the rotor still once the bail is opened for a cast. This brake is especially important in sizes 4000 to 10000 since they have automatic bail closure, meaning their bails can be closed by turning the handle, and if their rotors are free to spin their bails could close in the middle of a cast and snap the line. The full-size 18000 and 20000 have manual bail closure only, yet the brake is still useful because I don't want anything moving when I cast.

Other than shore fishing the new Stella came with me to Alphonse Island, Seychelles, on a 5 days trip where it landed 3 bluefins the biggest around 80lbs (36 kg), a nice GT roughly 25lbs (11 kg), a smallish Yellowfin, and countless bonitos while trolling between spots. The most remarkable challenge though was a fish that I never got to see; on our way back I was trolling, something impressive hit, took a lot of line to the point I began worrying that I might soon see the mono backing, but it eventually ended when my braid snapped. I can only guess what happened to the braid, but I suspect that the initial strike weakened it then it finally gave up. Trolling with braid straight is never a good idea because it lacks the stretch and shock absorption of mono, but I acted lazy and paid the price for that laziness.

I got to learn a lot about the 2008 Stella SW during these outings. The drag clicker has a very pleasant sound to it and it's clearly audible even in noisy environments, and the performance of this drag is like nothing I've seen before. Smooth startup with very little static inertia, it released line smoothly with remarkable consistency, there were no signs of overheating throughout, and the responsiveness of the drag was brilliant time after time releasing line quicker and with less structural flexing than any high end reel available today.

To the surgery table, still inside the bag that came with my JDM reel. It's designed to fit around the reel while it's mounted on the rod to protect it during transportation.

Good stuff right there.

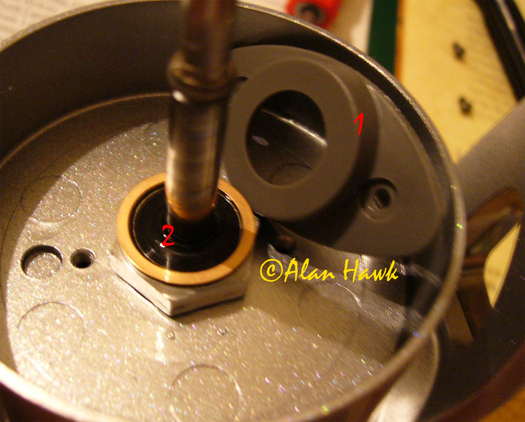

The upper drag stackof the 20000 shows some great engineering. #1 is the drag seal, which is a hybrid type one made by moulding rubber over a metal washer. This hybrid metal/rubber seal distributes pressure evenly for a more efficient sealing than a standard flat rubber seal. #2 in the above photo is the top spool ball bearing inside its metal housing. #3 is a thrust tube designed to transfer the pressure from the drag knob to the drag washers stack, passing through the seal and the ball bearing without putting any load on either.

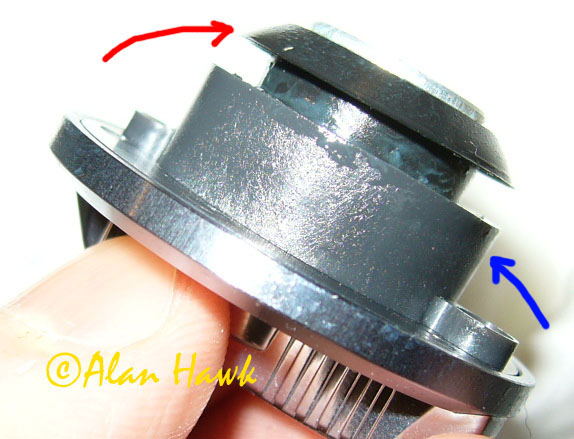

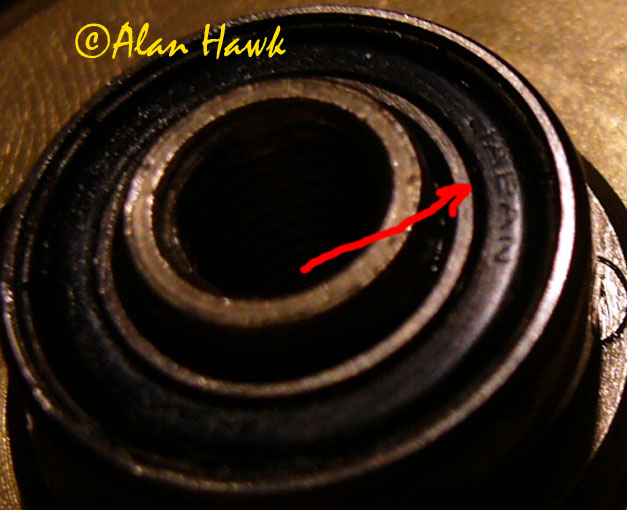

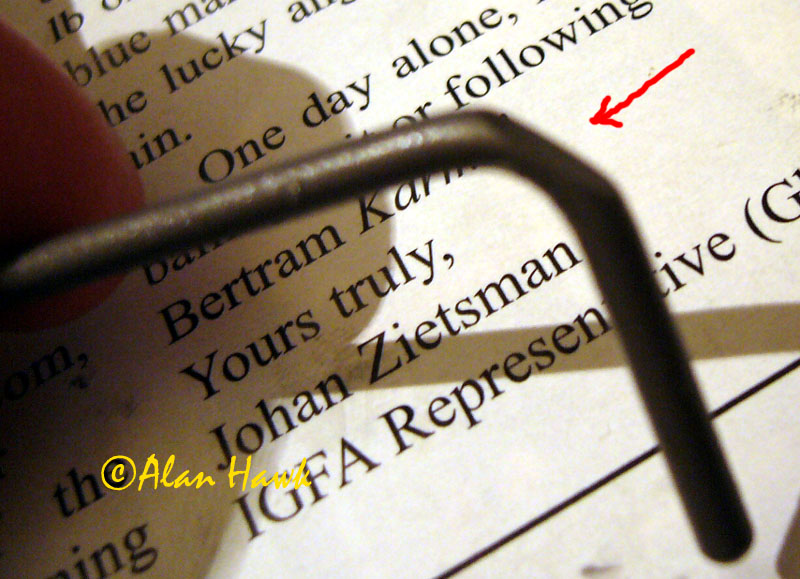

A seal mounted on the drag knob (red arrow) adds another layer of protection against water intrusion into the drag stack. What you're seeing here is the original design, but roughly 1 year into the production of the 2008 Stella SW Shimano added another seal in the area pointed by the blue arrow. It was discovered that the initial seal left important parts of the drag knob's internal mechanism unprotected, therefore that second seal was added to keep water out at an earlier point. That design change was done silently without announcements, which is something tackle companies do to avoid embarrassment when they think the alteration will go unnoticeable.

The knob's outer casing is made of machined aluminium, and it looks and feels luxurious, although I wish it had a larger gripping surface for easier control especially when wearing gloves. The drag of this new Stella increases more rapidly than the older model, meaning producing higher pressures takes fewer turns. The knob has an internal clicking detent mechanism that makes micro-adjustments easier. You also don't have to squeeze the knob hard to produce high drag pressures, since the large surface of the drag washers beneath the spool generates a lot of braking power at low stress.

Here is that bottom drag system. #1 is the screw-in drag assembly cover which comes only in 18k and 20k sizes. #2 are drillings that reduce the mass and therefore the inertia of the spool. In sizes 8kand up the spool is self-contained, complete with its bearings and protective seals. The previous 2001 Stella SW had some protective spool sealing in sizes 6k and up, but the bottom spool sealing of these reels was located on the main shaft instead. Daiwa's Saltiga Z is similar to that old Stella in this regard as seen in the following photo

In all Saltiga Z sizes the spool is fully sealed, but the bottom spool seal remains on the shaft (blue arrow) right above the bottom spool ball bearing (red arrow). The self-contained spool of sizes 8k and up of the new 2008 Stella SW is definitely a cleaner and more protective design.

Inside the bottom drag

#1 is the spool hub with a seal mounted on its bottom and another smaller seal on its top. That small seal fits in the thrust tube seen earlier in the top stack (5th photo above this one) to form an enclosed passage for any water that seeps around the main shaft and keep it away from the drag washers.

#2 is a metal drag washer and the red arrow points the drag clicker mounted on it.

#3 are two oversized brake drag washers, both are keyed to the spool's body so that in one of these washers both sides are utilised for the generation of braking, thus a single washer would be doing the job of two. To understand it better, imagine that you're holding two metal plates, one in each hand, and that a sheet of paper is sandwiched between them. If you rotate the metal plates in opposite directions, the paper will adhere to one of them and rub against the other, which is what happens with regular non-keyed drag washers. Now imagine that you bit on the paper with your mouth to keep it still then rotated the metal plates in opposite or same direction. This time the paper would not adhere to either metal plate and both would slide and rub against both sides of the paper. That's how a single keyed washer produces two braking surfaces. This reduces parts and saves weight.

Still in the above photo, #4 is the keyed recess of the washers, and in its centre sits the lower spool ball bearing retained by a wire spring.

#5 is the toothed raceway against which the drag clicker slams and produces sound. It's plastic, and it's removable so that when it wears out it can be replaced with a new one.

Pretty much everything I've just described makes up what Shimano calls "rigid support drag". Precisely manufactured parts that fit together without much clearance or play, therefore there is no tilting or twisting in the spool as a whole which helps with consistent drag performance and even wear in washers.

Handle grip

A plug seals the grip from the outer side, right beneath the Shimano logo plate .

Disassembled

The grip isn't sealed from the inner side, but it runs on two rubber sealedcorrosion resistant ball bearings. In the Saltiga Z they used a different approach where the ball bearings themselves are not sealed, but the grip is tightly sealed on both ends. Both approaches work well, but the one in this new Stella has less resistance and makes the knob freer and lighter to spin, adding to the reel's overall superior free-spinning mentioned earlier.

Another reason the 2008 Stella SW is more free-spinning than the Saltiga Z is the approach to protecting the handle's openings. The new Stella has a single seal mounted on the handle and it goes with it to whichever side, while the Saltiga Z has two permanent seals inside the gearbox, one at each end of the drive gear's shaft instead. This way when you turn the Stella's handle you work against the resistance of one seal only, while in the Saltiga Z you are resisted by two seals at all times.

Removing the rear body bumper

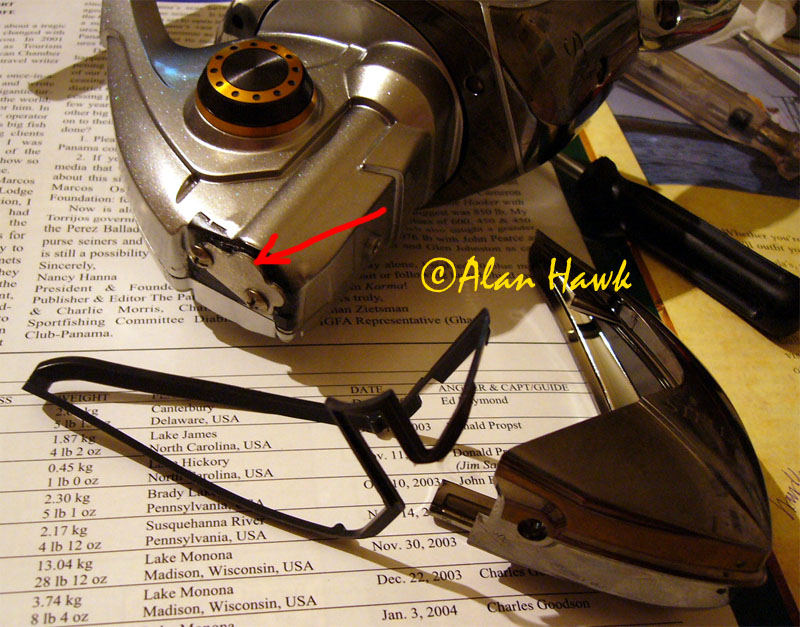

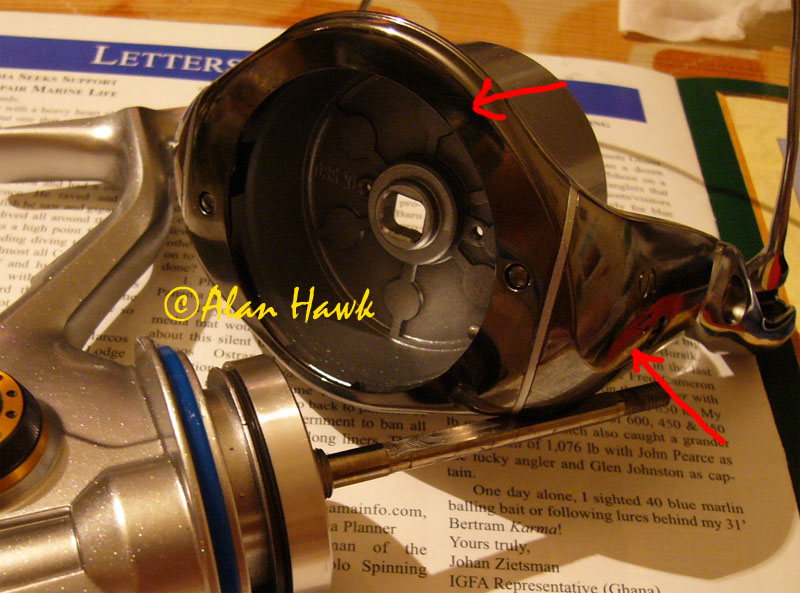

Behind this plastic body bumper, the oscillation mechanismis retained by a plate (red arrow). This plate is double-sealed to keep water out of the gearbox.

The bumper itself is not sealed due to its complex shape and water can therefore get behind it, so it has two draining holes to allow that water to leave. In the previous 2001 Stella SW there were no draining holes, so it was very common to see the body behind the bumper extensively corroded because saltwater would get inside then remain trapped. Consequently many people who bought that 2001 model would preemptively remove the bumper and heavily grease the area behind it before the first use.

Going deep

#1 is a plastic retainer that keeps the rotor's nut from becoming loose, and it also keeps the main shaft seal (#2) in place. This shaft seal is an improved design with a raised collar, which provides better sealing than the one used in the previous Stella SW.

Deeper

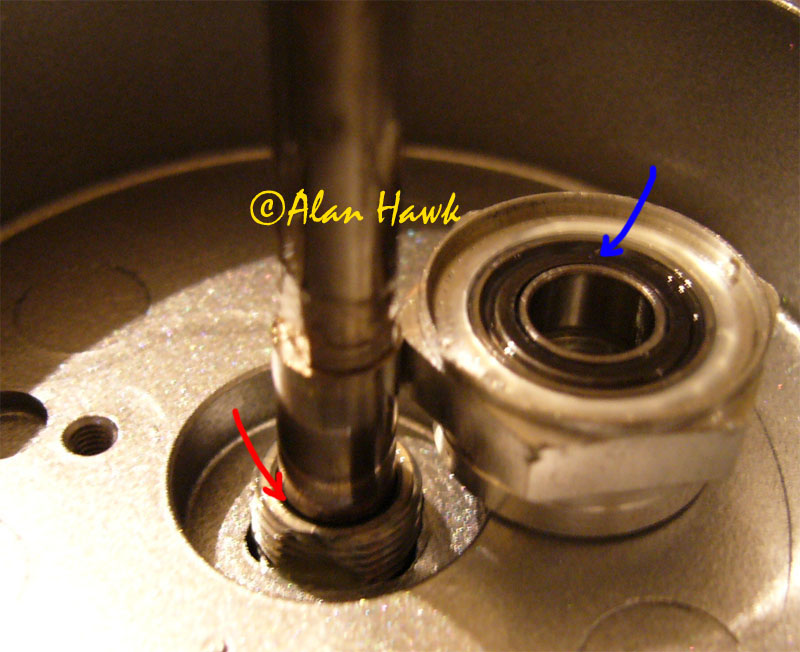

Removing the rotor's nut reveals a space between the shaft and the pinion (red arrow). This is the first half of the "floating shaft" system, in which the main shaft has no contact with the pinion to reduce friction and wear as well as provide a smoother winding under load. The ball bearinginside the nut (blue arrow) keeps the shaft in the centre of the pinion's hole without touching the pinion itself at all. Also when the rotor spins, this ball bearing eliminates the rotational friction between the rotor's nut and the shaft. You'll see the second half of this "floating shaft" mechanism when we get inside the gearbox later on.

Removing the rotor

The rotor itself is metal. It's hollowed out to reduce weight, then the voids are filled with plastic covers and floors (arrows). This plastic "skin" is pretty thin and has a fragile feel to it, but it works fine and resists dents alright.

Underneath the rotor

#1 is the rubber ring of the powerful rotor brake discussed earlier in this review. #2 is the new screw-in cover that retains the anti-reverse clutch and its seal. This screw-in cover is new to the Stella SW series, but it appeared previously in the 2001 Saltiga Z where Shimano saw it and decided to "borrow it" for this new Stella. #3 in the photo above is the clutch seal. Red arrows point a set of flat areas in the flange designed to allow a quicker draining of any water that gets behind the rotor. There is a similar set of flats at the opposite side of the flange which isn't visible in this photo. The brake ring becomes straight on top of these two flat areas (#4), which creates two locations where the rotor brake feels a bit loose since the brake lever doesn't fully engage the straightened and retreated ring in these locations. Not a big deal, I just like going into minute details and telling you about every quirk.

With the rotor and the brake ring off, the side cover of the reel's body can be removed

These are the side cover screws, and you can see that different types of thread-locker were used on them; high-strength red one on shorter screws, while longer screws got the medium-strength blue one since the difference in hold strength is balanced by the extra length. Of course what you see on the screws is not the entire spread of the thread-locker. Part of it remains inside the threads in the reel's frame. Applying different thread-lockers on different screws consumes time and labour, but that's what one expects from a flagship product assembled by the best people they have.

Guts!

#1 is the huge drive gear, #2 is one of the two ball bearings the drive gear runs on, #3 the flange's rubber seal, and the arrows point two stainless steel pins that precisely fit into corresponding holes in the frame for an exact alignment. There is no rubber seal between the frame and side cover, but I found the fit between their flat mating surfaces across the entire perimeter to be close enough not to allow water to enter the gearbox. If subjected to pressurised water though, as in deep submersion for example, water would certainly leak inside.

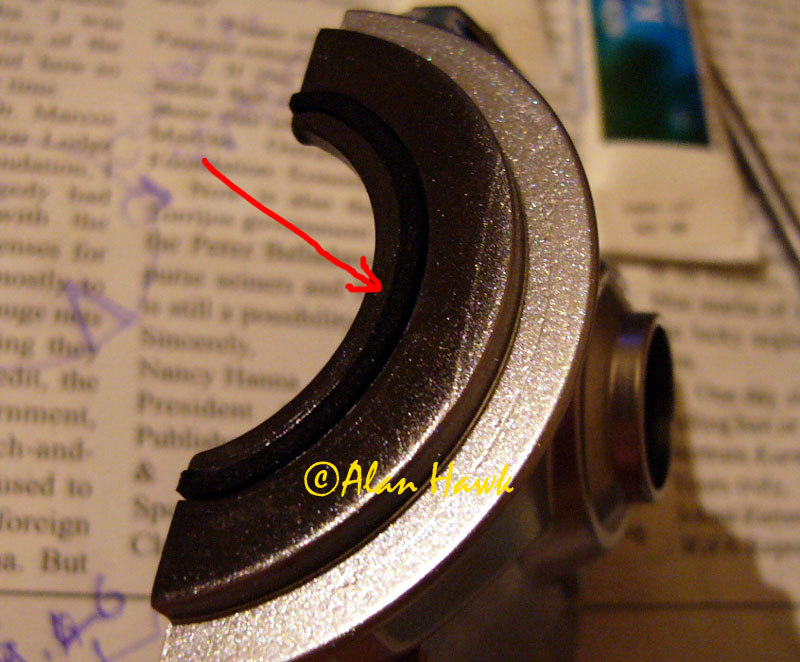

And here is a better look at the flange seal, shown only by edges in the previous photo.

All the ball bearings in this new Stella are Japanese made high-chromium corrosion resistant ones. They opted for the best money can buy today.

A closer look at the drive gear

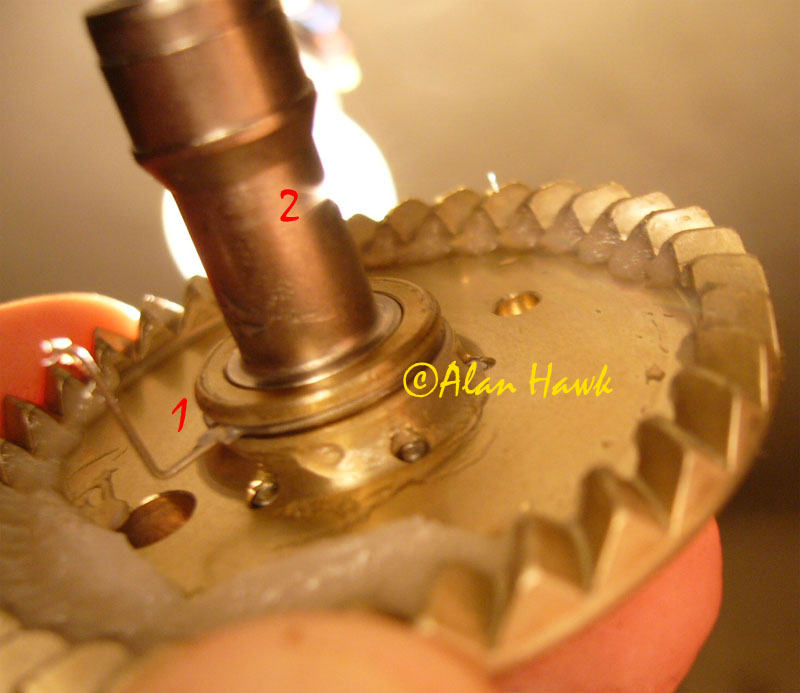

The drive gear is made by cold-forging a piece of light weight duralumin, then it's finished with a bronze surface coating. Cold-forging is an ingenious process where the metal is hammered into shape at room temperature, which increases the metal's density and surface hardness. Cold-forging does not interrupt the metal's grain flow, unlike machining, and doesn't break its molecular bonds, unlike casting. You end up with a gear that is extremely strong for its weight, and the bronze surface coating makes it even better by reducing friction thus extending its service life. The previous 2001 Stella had a cold-forged drive gear as well but with a black alumite surface coating instead, which is a good finish but not as durable as the one in this new Stella. #1 in the above photo is the wire spring that activates the backup anti-reverse, which you'll see later on, and #2 is the stainless steel female gear shaft.

An even closer look

Arrows and red dotting point the areas where the finish has a different shade on the surface of the metal, that surface having acquired extra hardness from the cold-forging process.

Still at the drive gear

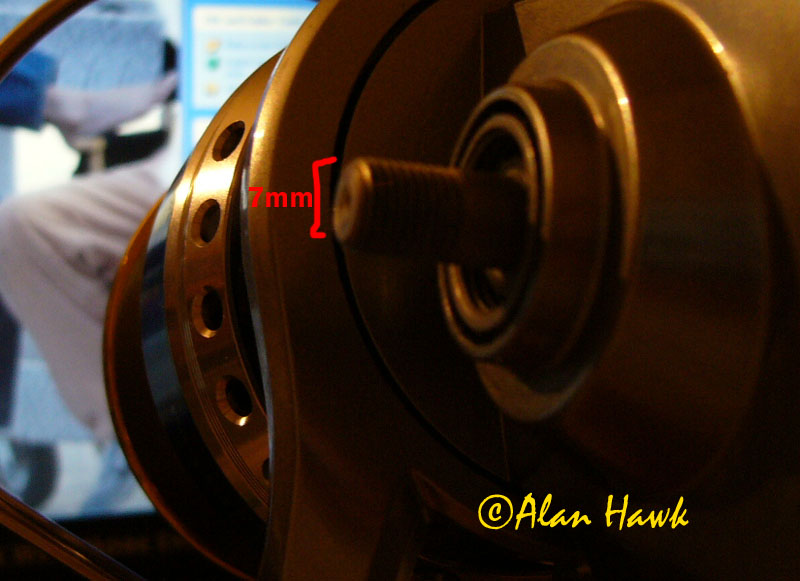

The arrow points to where they methodically reduced the thickness of the gear's shaft in order to lower the gear closer to the pinion and reduce offset as much as possible for a female shaft. Still not as close as the Saltiga Z with its thin male gear shaft, but this slight decrease in offset coupled with a much larger gear with improved geometry results in an overall higher cranking power. I felt it both during fishing and when I carried out some dry land testing later on.

The next paragraph could bore you to death, so skip it if you're not mechanically inclined.

****************** Boring ***********************

Why was it possible to reduce the thickness of the gear shaft in this new Stella SW?

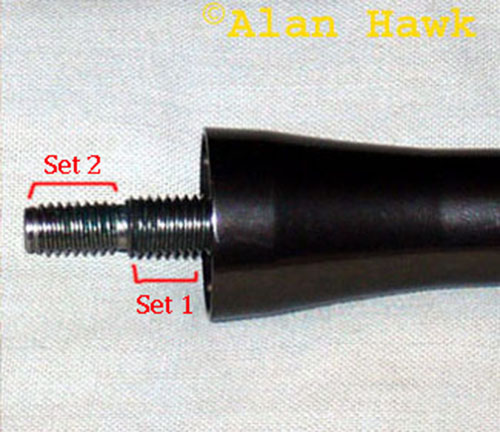

Sizes 6000 and up of the previous 2001 Stella SW had the common handle attachment design, where the handle shaft had two different sets of threads cut in opposite orientations, one set for attachment to the left side and the other for the right side. It looked similar to the following photo

That system is very convenient for quick winding side swap, but it requires a thicker gear shaft because both ends of that shaft need to accommodate the thicker of the 2 sets of handle threads. Also, the gear shaft needs to be hollowed out deeper in order to accommodate the extra length of the thinner of the 2 sets of handle threads, and consequently these extended hollow sections of the gear shaft would need to be thick or they'd be weakened due to being hollow.

For the new 2008 Stella SW though they made a change; all sizes come with two threaded handle shafts, one in the handle and the other as an extra in a plastic bag

Here it is. Now when you want to change the winding side you first need to swap the handle shaft. Not as convenient as the double threaded shaft setup, but it allows for lesser gear offset as described above as well as makes the handle attachment equally strong at either side since there isn't a set of threads that's thinner and potentially weaker than the other.

******************* End of boredom ***************

Pinion assembly

The pinion is stainless steel, a change from all past generations of Stella which had brass pinions. Stainless steel is a harder material that generally produces noticeable gear noise, but paired with the cold-forged and bronze coated drive gear in this reel I found the operation to be every bit as smooth as the previous model. The drive train is now tougher and more durable without loss of smoothness. #1 in the above photo is the pinion's inner ball bearing, #2 is the pinion's outer ball bearing in its sleeve, and #3 is a pair of stainless steel ratchet gears that's a component of the backup anti-reverse system ready to step in if the main clutch ever slips.

This main clutch

It's a Shimano proprietary design, and it is without a doubt one of the most advanced anti-reverse clutches to ever be in a spinning reel. Its very large ring (#1) is directly keyed to the frame for maximum strength, its seal (#2) is also the hybrid rubber/metal type discussed earlier, and it has a light weight cover (#3) to keep all the little components in place.

These little components

The grey cage houses the brake cylinders, each cylinder having its own tiny coil spring which keeps it pushed against the centre sleeve to instantly stop that sleeve from rotating backwards.

There are generally two types of clutches used in spinning reels; "spring type" where the brake cylinders are under constant spring pressure, and "non-spring type" where the cylinders have no springs and instead rely on having slight contact with the centre sleeve at all times in close confinement. Non-spring type lasts longer, but it's generally more prone to slippages and has a tiny amount of back play before it locks. Spring-type is less likely to slip and has firm immediate locking, but in almost all clutches used in spinning reels the springs are V-shaped plastic limbs moulded into the cage, and with extended use these plastic limb springs lose their elasticity and no longer apply sufficient pressure causing the clutch to slip frequently. This Shimano-designed clutch therefore has the best of both worlds. It has the immediate reliable stop of the spring type, and it should last as long as any non-spring type since its springs are metal ones that will not lose elasticity or cease to apply appropriate pressure.

Back side of the clutch's cage

The plastic cage, whose sole responsibility is retaining the components, has moulded pins in its back that only let it fit into the reel's frame in one predetermined position.

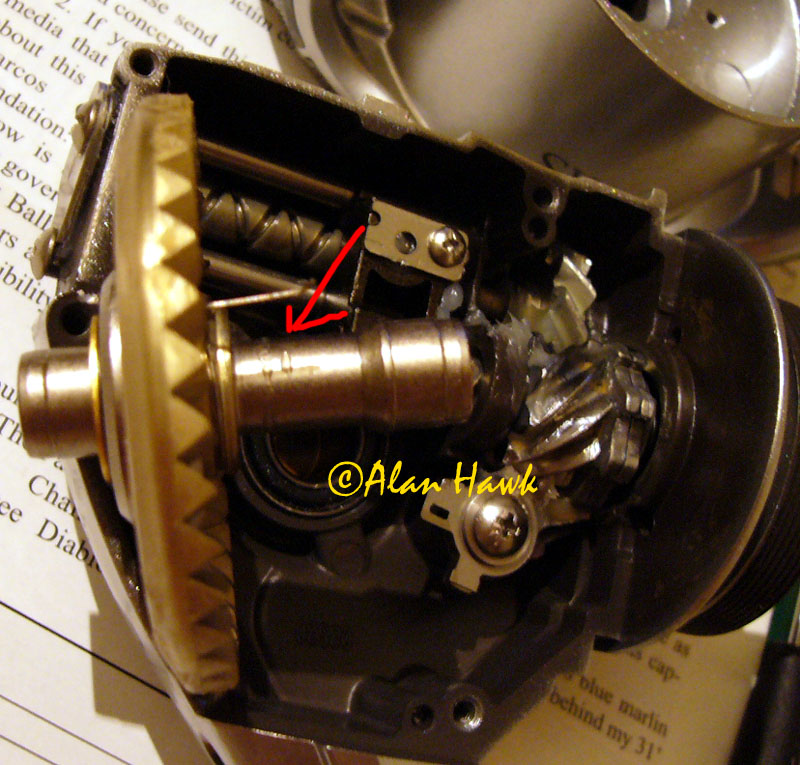

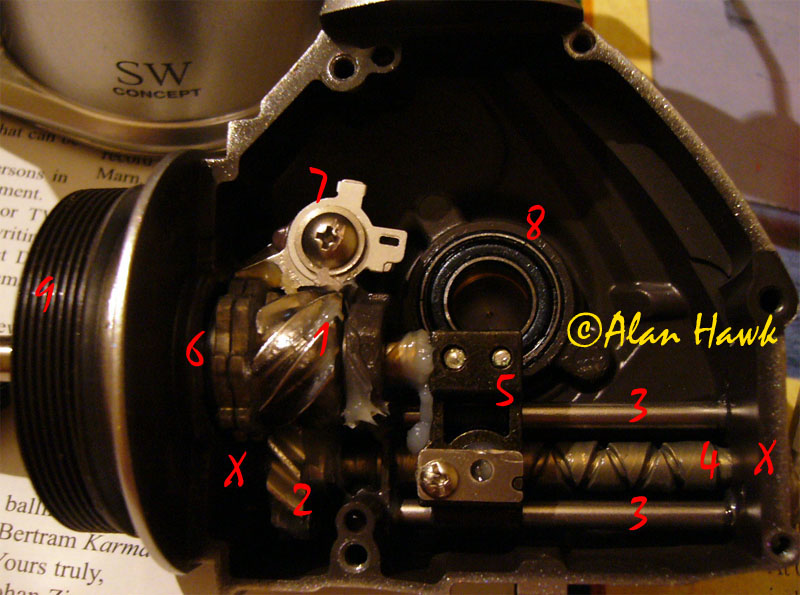

A crowded photo showing gearbox components in their final operational positions

#1 is the pinion. #2 is the oscillation gear. #3 are two stainless steel rods on which the oscillation block (#5) is mounted. #4 is the oscillation worm shaft. #6 are the backup anti-reverse ratchet gears. #7 is the final component of the backup anti-reverse system, which is a dog that's activated by the aforementioned wire spring on the drive gear's shaft to engage the ratchet gears and stop the rotor if the clutch slips. It's worth noting that this backup anti-reverse system has been copied from the big 2001 Saltiga Z reels. Neither the 2001 Stella SW nor any previous Stella had a backup anti-reverse of any kind. Also need to mention that only sizes 8000 and up of this new Stella SW have a backup anti-reverse. Smaller reels don't have one.

Still in the picture above, #8 is the other ball bearing of the drive gear. #9 are the threads of the clutch/bearing assembly cover shown earlier. And the two Xs point the locations of the two tiny ball bearings on which the oscillation worm shaft is mounted. Here we see that Shimano went back to the direct contact between the pinion and the oscillation gear. In 2001 both saltwater and freshwater Stellas came with an intermediate set of gears between the pinion and the oscillation gear, supposedly to tune the spool stroke for a better line lay, but I found them to be completely redundant and needlessly add weight, complexity, and more parts to wear out and possibly fail. Now this gimmick is gone, and the new Stella SW lays line beautifully and no one is complaining or missing that clump of unnecessary parts.

Rear look

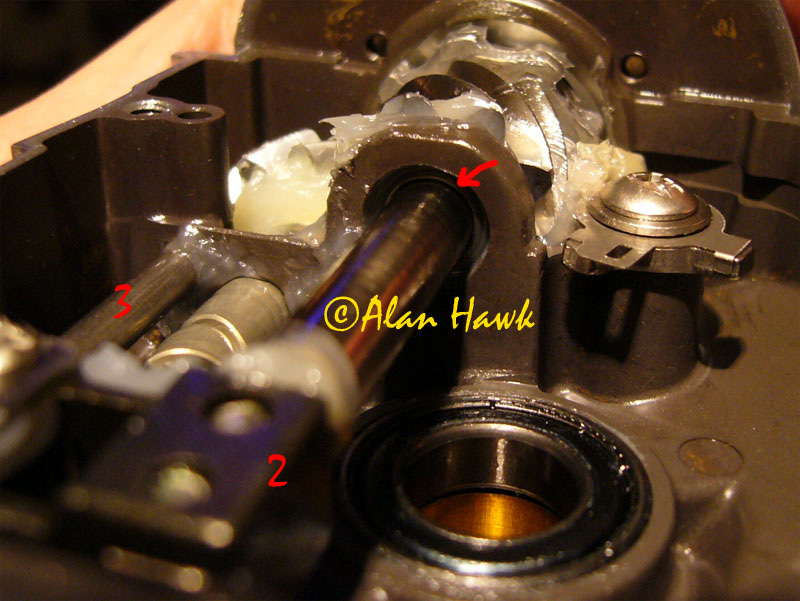

This is the second half of the floating shaft system. The arrow points to a slight clearance between the main shaft and the pinion where there is no contact between them, and instead the shaft is carried by the oscillation block (#2) which in turn is mounted on the two steel rods (#3), ultimately securing a complete flotation of the main shaft without friction with the pinion.

Adult photo. Anyone under 18 don't look please!!

#1 is the naked body of the reel with everything off, a state that's reached after a tough job disassembling an extraordinary number of intricate parts. #2 is the oscillation worm shaft out for a better look, and you can see a tiny rubber ring on its fore part to reduce and dampen play between it and the oscillation gear (#5). #4 are the two tiny ball bearings of the worm shaft. And #3 is the very expensive but magnificent performer Dupont Krytox Teflon grease I currently use in my premium reels,

A closer look at the oscillation mechanism

The way this mechanism works is as follows: the stainless steel pawl (#1) is inserted into the hole in the oscillation block (#3) so that its thin edge sinks into the grooves in the worm shaft (#4), then a washer and a tiny ball bearing (#2) are inserted on top of the pawl both to retain it and to secure a smooth rotation for it as it slides back and forth across the grooves pulling the main shaft up and down with it. In general, due to the small contact surface between the grooves and the thin edge of the pawl, worm shaft oscillation isn't as strong or durable as the locomotive gear system found in the majority of spinning reels. It has a distinct advantage though, which is it allows for a longer oscillation stroke, meaning a bigger distance between the spool's top and bottom positions, thus the spool can be made taller for increased capacity and better casting. In this Stella the components are top grade and the tolerances are excellent, so one expects this oscillation setup to serve as well as any other worm oscillation system in existence.

The hidden side

The block is a heavy cast alloy, and it rides the two stainless steel rods shown earlier via these two holes.

Look at this

The Saltiga is a handsome reel, but the curvy lines of the new Stella make the Daiwa look boxy in comparison. Of course beauty is in the eye of the beholder, so that's only my subjective opinion.

The line roller

Wide enough for very thick leaders, hard finished in black, and is very light to spin.

The bail wire

One-piece bail wire that lets the line slide uninterrupted all the way to the roller. The principle of a single piece bail wire without joints is also stolen from the 2001 Saltiga Z, but the 2008 Stella SW improves on the Saltiga Z's design; in the Saltiga when the line clears the one-piece bail wire it lands briefly on a narrow strip of the roller's housing before it reaches the roller itself, while in this new Stella the line goes straight from the wire onto the roller with nothing in between.

The yellow pin, whose head is visible in the photo above, is a separate part and it's what holds the line roller assembly together. It's designed in this modular fashion because Shimano sells a bailless kit under the "Yumeya" name, which is Shimano's custom shop, and the modularity makes the conversion an easy task

Here is the kit. You only need to pull the yellow pin out, remove the bail wire, replace the yellow pin with the silver one from the kit, then attach the counter-weight from the kit to the other side using existing screws. That's all. Now you have a bailless Stella.

Line roller disassembled

The line roller itself is not sealed, but the two small ball bearings it runs on are rubber sealed (#1). #2 are the bearings' sleeves. #3 and #4 are shimming washers. And #6 is the line roller itself which is finished with "diamond-like carbon coating". This finish is essentially a depositing of carbon on the surface through a complex operation that takes place in a vacuum chamber, ultimately creating a very hard and low-friction surface.

Bail mechanism

Simple and reliable, and the arrow points the lever which engages the rubber brake ring (shown earlier) to hold the rotor still during a cast.

That level is well thought of

It's partially filed at the curve so it won't hit the bail mechanism cover when it slides down. This is impressive attention to details.

Opposite side

The counter-weight that balances the rotor is disguised as the bail wire's end piece. This is why when you remove the bail wire (which includes this end piece) to convert it to bailless you must attach a counter-weight to this side.

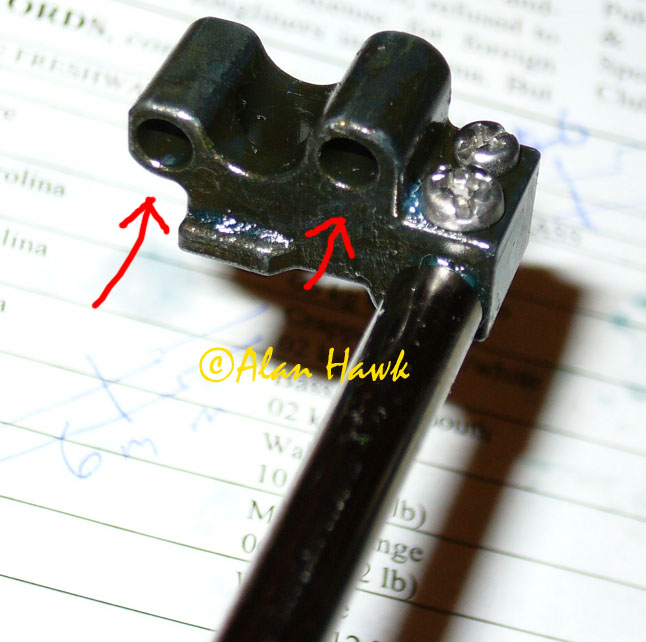

And finally, the back of the bail arm

That's some elaborate work to make sure the line roller assembly doesn't become loose during use. The main screw (#1) is captured by a metal plate (#2), then a tiny screw (#3) captures the plate that captures the screw. This seems incomplete to me; there should be a third screw that captures the little screw, and that third screw would then need a plate to capture it, which in turn would require its own screw, and so on until the entire frame of the reel is covered in plates and screws. Nah just kiddin'. I like the work they've done and it certainly fully secures the assembly.

In conclusion, a modern reel is simply three things; a drag, an anti-reverse, and strong gears. There are other important aspects such as sealing, finish toughness, smoothness, casting, etc., but all take second place to those three things that make or break a reel. The gearing of the new 2008 Stella SW is immensely strong, its anti-reverse clutch is as good as it gets, and its drag is going to change fishing as we know it today and I won't be surprised if more people put down their small multipliers and picked this Stella instead. Additionally the new Stella SW has become lighter, it's built to high standards with very tight tolerances, and they didn't hesitate to rob the best features of the Saltiga Z for their new baby. That's not something I'd hold against Shimano since both companies have been lifting ideas off each other for as long as I can remember.

In my book, the eternal debate of "Saltiga Z vs Stella SW" is over with a clear winner. It was debatable when the Saltiga Z went head to head with the 2001 Stella SW, but that groundbreaking Daiwa simply stands no chance against this latest reincarnation of the Stella. This new SW is not for everyone, nor is it something that people won't be able to live without. It's just a beautiful expression of what humans can achieve in absolute refinement, luxury, and engineering perfection when money is not an object, and I simply wanted to share this expression with you.

Hope you have enjoyed this.

To support this site and my work, please click here

Alan Hawk

March, 1st, 2009