2013 Shimano Stella SW (SWB): The Review

Hello all

Basically 99 out of every 100 anglers in the world have heard of the Stella, but for the 1 in 100 who hasn't, it's Shimano's flagship spinning reel which came to life exactly 20 years ago. It was in the year 1993 that the first Stella made its debut as a spinning reel built to the highest possible standards, with a price tag nearly 4 times as much as the most expensive spinning reels available back then. These first Stellas were small freshwater reels in sizes up to 4000 only, then a couple of years later the series grew to include big saltwater reels up to 10000 size.

This is a 10000 reel from that first saltwater series of 1995.

A hallmark of the Stella since the very beginning was the extreme smoothness and free-spinning, mostly thanks to the large number of ball bearings it had, including in such unusual locations as inside the line roller, at both ends of the worm shaft, and in the centre of the spool. Another characteristic of the Stella was the build quality and durability of parts, so much so that many of those first reels are still in service today. The most distinct characteristic of this reel though was the exceptional drag performance, something very few other reels could compete with. During the two decades of its existence the Stella morphed and changed, but those attributes remained with the reel, so did its status as a luxurious spinning reel coveted by most anglers.

It even appeared in a cartoon..

Have no idea what's going on here, but this guy looks at the 2008 Stella SW the way a man looks at a woman, not a fishing reel. I do the same thing, sometimes.

I was quite surprised when news about a new Stella SW broke late last year. The 2008 Stella SW was selling very well, outperforming its competition the 2010 Saltiga in sales outside of the Japanese market, so a 5 years life span seemed extremely short for such a successful reel. Could it be that Shimano has created such a groundbreaking reel that they were willing to send the 2008 model into an early retirement for it? I needed to find out, and had originally intended to take my sweet time with this new 2013 model and publish this review in August at the earliest, but since nearly 3 out of every 10 emails I received in the past two months were enquiring about this reel, I decided to put other projects on hold and fish this new Stella as much as I could to fast-tack this report. Having put nearly 150 hours of use on it, I finally believe that I'm ready to share my findings.

Will begin with a few photos taken when I first unboxed it

The box is notably larger than previous generations, it's nicely made, and sticks Shimano's habit of colouring the Stella's box to match the reel itself; the silver 2008 model came in a silver box, the blue 2001 reel came in a blue box, etc.

The box is larger because they integrated a protective cardboard padding into it this time. Previously, the box of the reel would slide into an external plain cardboard box for protection, and it was common for retailers to throw away that external box. The new way guarantees you get the "full set", and overall it's more user friendly.

The reel definitely looks better than the previous generation. The previous model had a certain "tameness" about its looks due to the rounder and smoother lines, while this new reel has an aggressive streak thanks to the sharper and more angular outlines of the frame coupled with the big pointy cuts in the spool's skirt. That aggressiveness is neither excessive nor veiled. It's a step up from the 2008 model, but not a "leap" if you understand what I mean.

Two issues I have with this new look though

This screw (red arrow) is an aesthetic abomination. The way it protrudes kills the flow of the contours and makes it stick out like a sore thumb. It was placed there for a functional reason that I'll explain later, but as far as looks are concerned it's just terrible.

Also this

The body is now even wider than the previous model, which already had a pretty wide body. This makes it disproportionate to the rest of the reel and gives the new Stella a "bottom heavy" appearance. Looks are subjective anyhow, so let's move on to something else.

Each reel has an individual serial number, and the round sticker to the right tells a few things about the reel, something that not many people know; the first letter from the left indicates the year of production, with "A" being 2002, "B" 2003, "C" 2004, etc. The second letter is the month of manufacture, with "A" being January. The letter after the dash is the symbol for the factory where the reel was made, "S" being Shimano's Japanese factory and "P" the Malaysian one. Therefore my sticker states that the reel was made in April 2013 in the Japanese plant. Of course all Stellas are and have always been made in Japan.

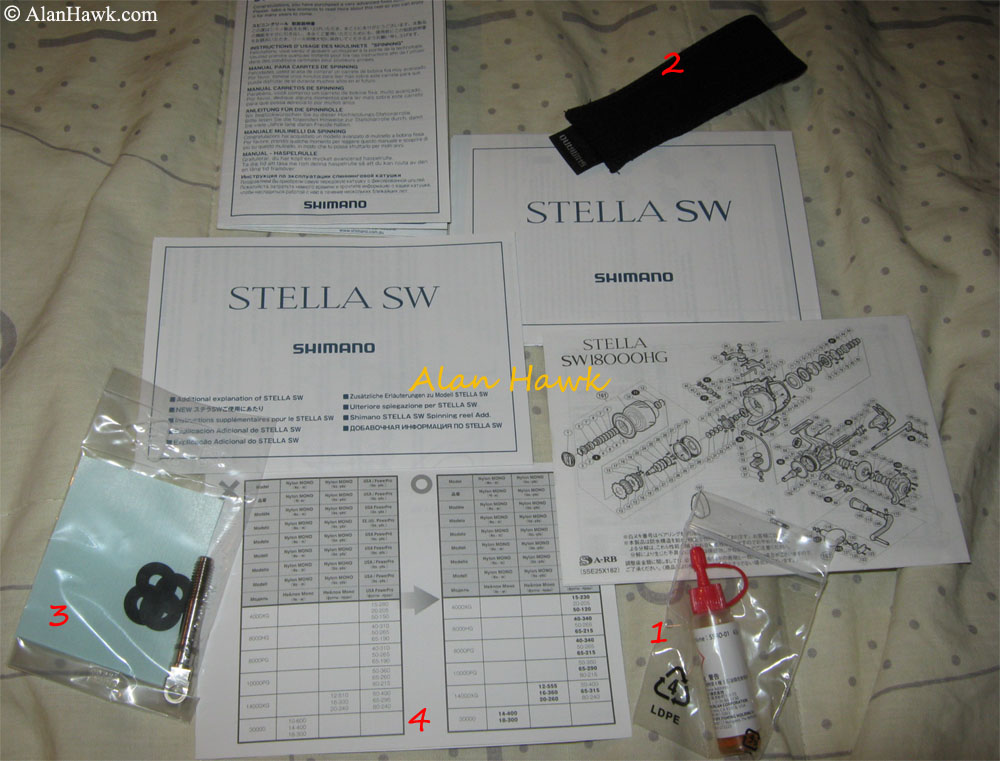

The reel comes with an instruction booklet and a manual in 9 languages, a small oil container (#1), a spool band (#2), a printed correction of previously misprinted line capacities for some models (#4), a plastic bag (#3) which contains shims to adjust line lay, braid sticker to keep braid from slipping on the spool, and a spare handle shaft for right hand winding. In this new generation, only sizes 8000 and up have a separate handle shaft for each side, while smaller reels have the common double threaded single shaft that can be screwed into either side.

It also comes with a bag, which has been redesigned and now includes a very practical carrying strap (red arrow). Now I don't have to "pinch" the fabric when holding it as I had to do with the previous "strapless"design. The bag is still embossed with the "Stella" name, but the spool band (previous photo) now only says "Shimano" instead of being marked with the Stella name as was the case previously.

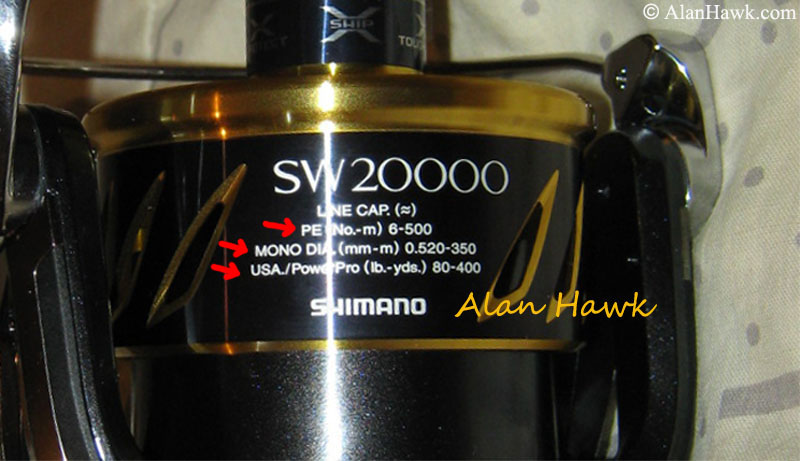

Need to mention a very important change here; previously Shimano made two versions of the Stella. One for sale in the Japanese Domestic Market (JDM) which came with Japanese language paperwork and packaging, and another export version for sale in global markets, which was slightly altered cosmetically and came with paperwork and packaging in different languages. That was done to make people buy from their own markets via the domestic sales network and at the price set for each particular geographic location. It's similar to the regional coding of DVDs where for example region-1 DVDs work in America but not in Europe where the DVDs are coded for region-2 or Australia where region-4 coding is used, etc. Anyway, to cut costs the new 2013 Stella SW comes in one version only that's sold everywhere, and this is why it comes with multilingual paperwork and its spool has the line capacities listed in different regional styles....

.... PE for Japan, millimetres and metres for Europe and most of the world, and "USA" line capacity for.... well, Argentina maybe? Seriously though, specifying "PowerPro" on the spool is cheesy. That braid brand has been acquired by Shimano, and apparently they decided to use the Stella's body as an advertisement board which cheapens the reel in my opinion.

Another change to the series is the addition of a new gigantic 30000 size. The new 30000 has the exact same body as the 20000-PG, but with a bigger rotor and spool. Since they share the mechanism, both the 30000 and the 20000-PG have a gear ratio of 4.4:1, but of course the amount of line retrieved per handle's turn will be more in the 30K than in the 20K due to the larger diameter of the spool. The 30K also has the same drag unit as the 18K/20K reels, but its maximum drag output is less than those two also due to the increased diameter of its spoolas laws of physics dictate. Shimano lists the 30K as having a 20KG (44lbs) of maximum drag instead of the 25KG (55lbs) it lists for the 18K/20K. The 30K weighs 990 grams (34.9 oz), and has a line capacity of 600 metres (~660 yards) of PE8 (0.47mm) line. This reel belongs to a new class of extra big spinners which I'm calling the "Mammoth" size class, and at the time of writing there is only one other member of that class which is the TwinSpin 50 whose actual weight is 1211 grams (42.7oz) and has a listed maximum drag of 18KG (40lbs).

The new Stella comes in 5 size classes, and within each of these classes the spools, handles, and drag knobs are interchangeable. The tiny size class only has the 4000 reel. Then there is the small size class which comprises the 5000/6000 reels. After that comes the medium class comprising 8000/10000/14000 sizes. Followed by the fullsize class with the 18000/20000. And finally the aforementioned Mammoth class with the new 30000 Stella. There is also good compatibility between the previous 2008 models and these new 2013 reels; spools are interchangeable between the old and new 4000 size reels, and between the old and new 5000/6000 size reels, and between the old and new 18000/20000 size reels. Unfortunately though the spools of the new 8000/10000/14000 reels wouldn't fit on the bodies of the old 8000/10000 reels due to the larger main shaft washers of the old reels. There is a way around that by replacing those big main shaft washers of the 2008 reels with the smaller ones from the 2013 models, but I do not recommend that since in this medium size class the spools of the new reels generate more drag power than their counterparts in the previous model, which might overload the old reels with more stress than they were designed for. The bodies of those 2008 Stella SW 8000/10000 were designed with a proper safety margin for the maximum pressure generated by the old spools, but not the increased drag output of the new spools.

The weights of the reels have increased over the previous generation. My 20K weighed exactly 885 grams (31.2 oz) on the digital scale, an increase of 40 grams (1.4 oz) over the previous model. Actually the whole line has increased in weight by 40-70 grams (~1.4 oz - ~2.5 oz) over the same sizes of the 2008 generation. This makes the new Stella heavier than some similarly sized super-spinners made by the competition; the 2012 Catalina 6500H weighs 799 grams (28.1 oz), the 2010 Saltiga 6500 weighs 828 grams (29.2 oz), and the Penn Torque 9 weighs 870 grams (30.6 oz). Another thing that has changed from the previous Stella is the free-spinning, which is the ease of turning the handle (erroneously called "smoothness" by many); the new Stella is tighter to spin than the old one, and while the margin is not very big it remains quite noticeable. When I reviewed the 2010 Saltiga I said that it has an edge over the 2008 Stella SW in free-spinning, that edge has now become a large gap between the Saltiga and this new Stella due to its decreased free-spinning. Finally, the price of this new 2013 Stella generation has gone up considerably, reaching $1260 for the 18K/20K and $1160 for the 8K/10K.

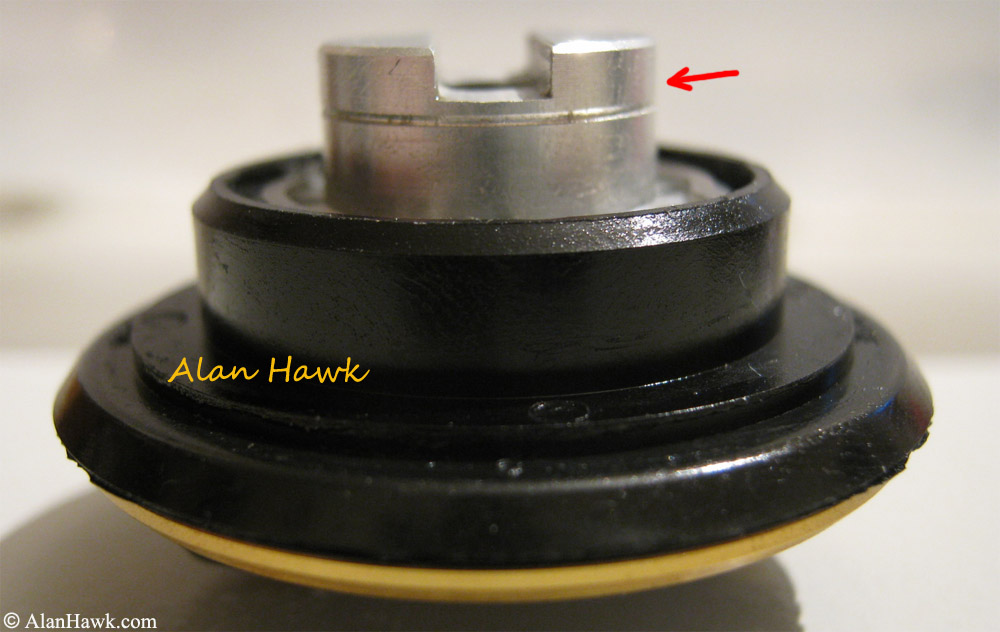

Speaking of sealing, the drag knob has a new seal (red arrow). This seal keeps water out at an earlier stage than the knob seal of the old Stella, which sat deeper inside the spool.

The pressure disc (red arrow) is metal and is slotted to save weight and as a means of keying to the shaft.

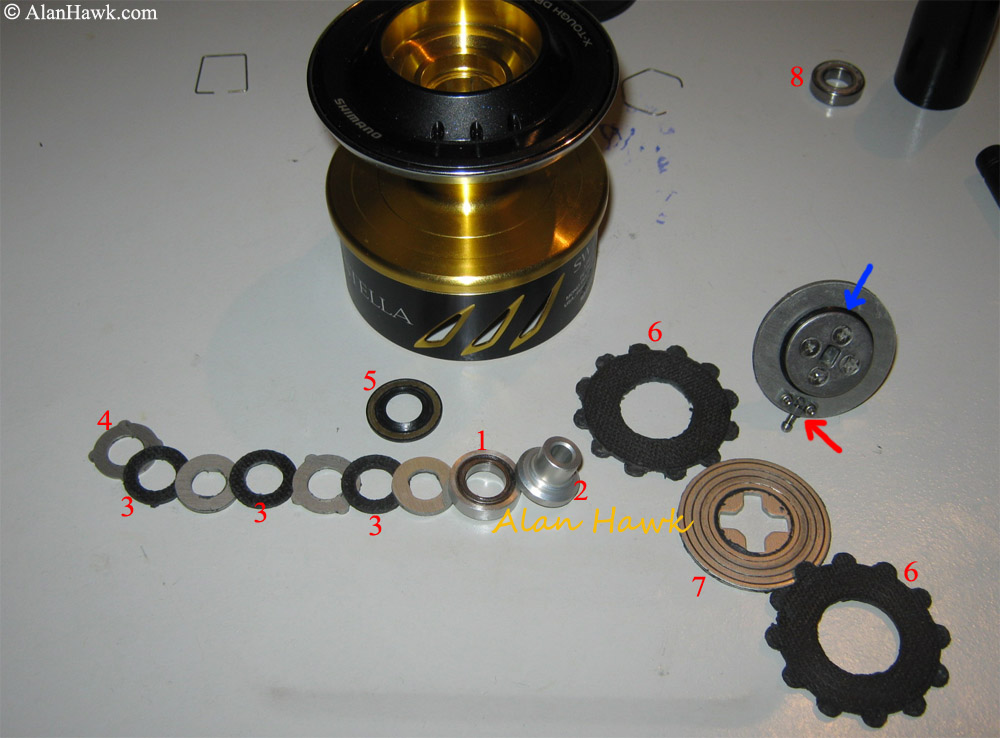

The drag composition remained virtually the same. #1 is the top ball bearing of the spool, #2 is the thrust tube, #3 are the top stack carbon fibre brake washers, #4 is a newly added eared washer so that the first carbon washer would rub on it instead of rubbing directly on the spool's body, and #5 is the seal of the top stack. The bottom drag unit comprises 2 large eared carbon fibre brake washers (#6), grooved metal washer (#7), the red arrow points to the drag clicker, the blue arrow points to one of the two bottom seals, and #8 is the bottom bearing of the spool. Other than the added small washer in the top stack everything comes directly from the 2008 reel. Well, almost everything

This is the bottom spool bearing. A regular bearing made in Thailand. When I reviewed the 2008 Stella all the bearings were ARB (Anti Rust Bearings) made in Japan, now the new Stella has a mixture of Japanese and imported bearings, ARB and regular. Makes me wonder if they had made that change in later 2008 Stellas as well since the one I reviewed was an early reel. The all Japanese ARB bearings of the old Stella was a very nice touch that I'm saddened to see go, but it remains an aesthetic issue that has nothing to do with performance so I won't dwell much on it.

The red arrow points to the second of the two bottom spool seals. The spools of the new Stella are 100% waterproof.

A major change took place in the medium reels. In the previous generation only the 18K/20K had the large double disc drag beneath the spool, but now the 8K/10K/14K have that drag as well as you can see in the above photo of a new 8000. There are slight cosmetic differences but it's basically the same twin disc drag of the large reels.

The drag performance of the old Stella was clearly above any other super spinner, and even Daiwa's hardcore fans wouldn't disagree. As unrealistic as it may sound, Shimano still managed to improve on that incredible drag. My very first fish on the new Stella was a 16KG (~36lbs) Amberjack in 90 metres of water, and once it started pealing line off the spool I could feel a degree of consistency that was like nothing I have experienced before. Let me explain what I mean; when a fish pulls the line off a spool the line doesn't come from right underneath the line roller, but rather it's pulled from the entire length of the spool top and bottom in continuous cycles, which creates slight and rapid fluctuation in drag resistance as the line is being pulled. That's why the tip of the rod "twitches" during a run even as the fish pulls with consistent power. This video taken while trolling should demonstrate how the line comes from different areas on the spool as the bail arm remains still

The slight fluctuation in resistance that I'm talking about is a natural phenomena that increases with the increase in the length of the spool, and is most noticeable in surf reels with very long spools. In the new Stella that effect has been minimised to a point where it's not perceivable anymore even to a complete geek like yours truly. Since the drag components come directly from the old model, the improvement certainly comes from the knob

The knob disassembled. #1 is the shaft nut, #2 is the assembly retainer, #3 is the pressure disc with the clicker holes, and the red arrow points to the spring loaded knob clicker. #4 is our man. This is the much talked about new wave spring

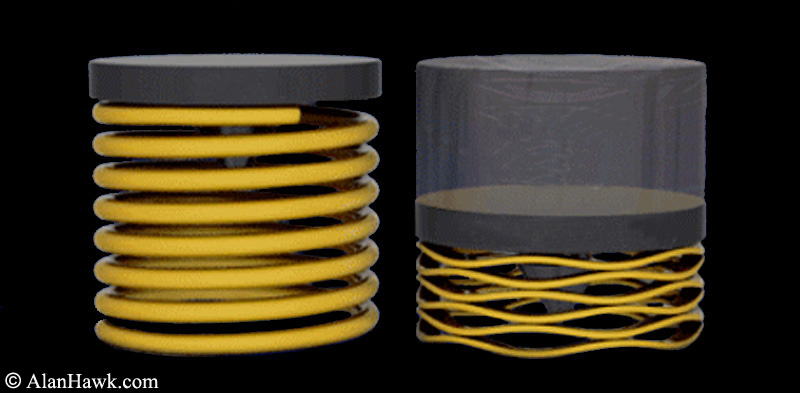

The purpose of a spring in the drag knob of a spinning reel is to keep the application of pressure uniform as the spool gets pulled and pushed by the line leaving from top and bottom of the spool as shown in the video, and to compensate for heat expansion in the metal components of the drag. The springs used for this purpose are regular wire coil springs, and to the best of my knowledge the 2013 Stella is the first reel to have a wave spring in the knob. The following paragraph is a short explanation of the wave spring and how it compares to coil spring

Without getting too technical, wave springs (right) are more laterally stable than coil springs (left), have more precise load deflection behaviour, and are about 50% smaller than regular coil springs that produce the same force. Because of the limited space inside a drag knob, the coils of a regular coil spring would be touching at high drag settings, making the spring function as a solid tube rather than a spring. When that happens it eliminates the aforementioned positive effects of the spring on the smoothness and stability of the drag, and it makes the drag progression spike sharply. For example instead of the drag pressure increasing by 4KG for each turn of the knob at the beginning, it increases by 7KG for each turn of the knob when the coil spring is fully compressed. A wave spring is smaller, thinner, and more stable, so it doesn't fully compress even at the maximum drag, which keeps drag progression linear and, more importantly, maintains the spring characteristic and its positive effect on the drag's smoothness and consistency. I have no doubt that the consistency improvement I felt in the drag performance comes down to this spring.

Underneath the spool a clean shimming design allowing easy addition or removal of shims to adjust the line lay on the spool. In the Saltiga this part is a complete mess as I describe in detail in its own review here. Daiwa's flagship reel comes with one shim in place, and all you can do is to add just one more. You can't remove the one that's originally there because then the spool would rest on bare metal, and if you add two shims the last one would not be held down and would move freely to become wedged beneath the bearing, that's in addition to the extreme difficulty of manoeuvring the shims up and down the hub of the Saltiga without damaging the two O ring seals. Not only does the Saltiga lose here to the Stella, actually it loses also to the Catalina which has a cleaner design than the Saltiga as I describe in the Catalina's review here.

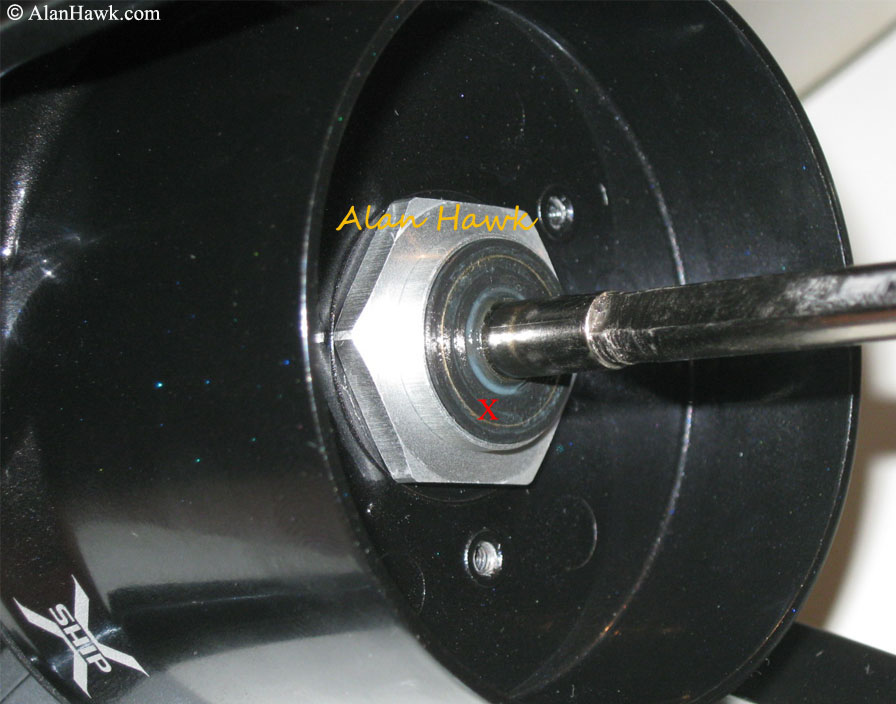

Just like the 2008 Stella, there is a shaft seal (red X) where the shaft enters the body.

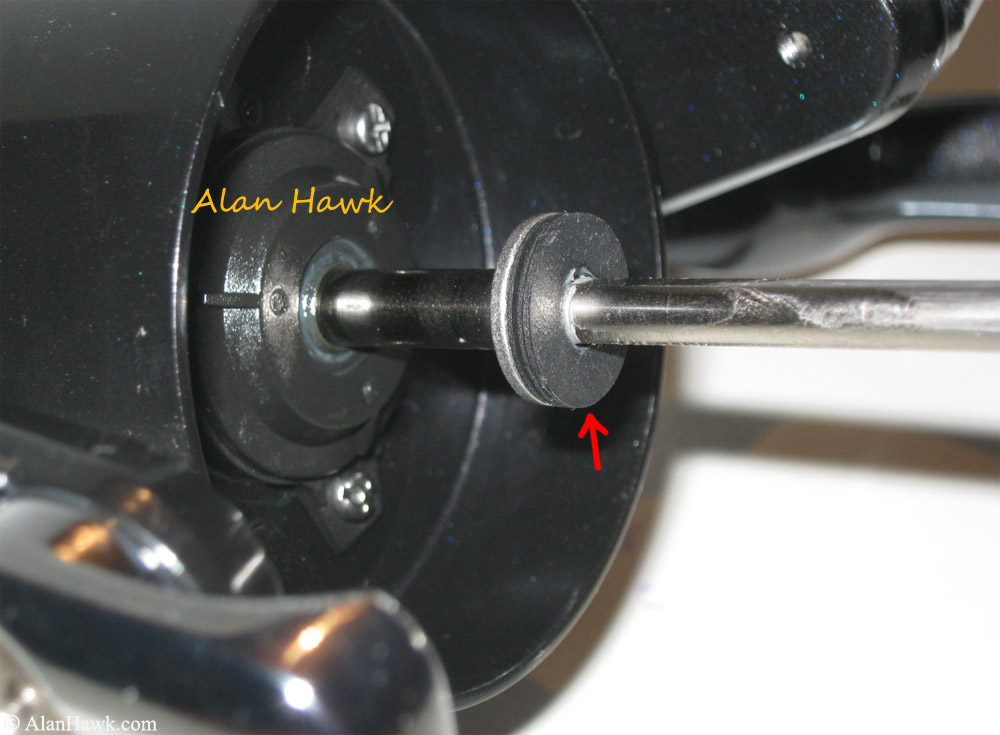

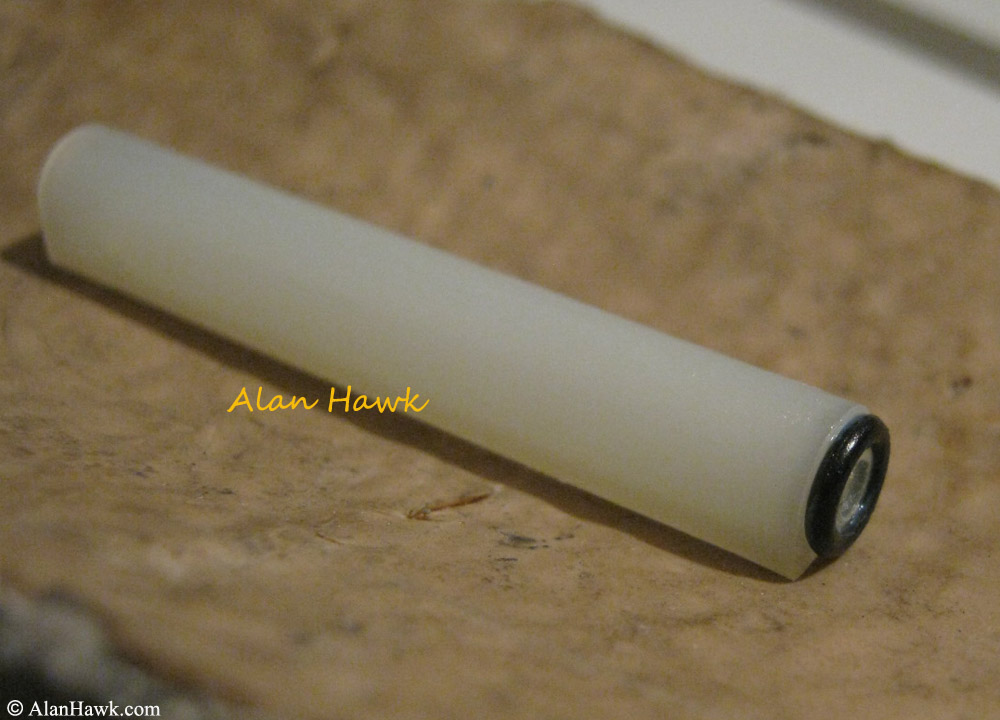

Inside the nut you can see the ball bearing responsible for the "floating shaft" feature, which reduces friction between the pinion and shaft, and the red arrow points to a new synthetic washer between the shaft and the bearing. In the old Stella only sizes 6000 and smaller had this washer while in sizes 8000 and up the shaft went directly through the ball bearing without a washer. All sizes of the new Stella has this washer.

A closeup on the washer. I will get back to it shortly.

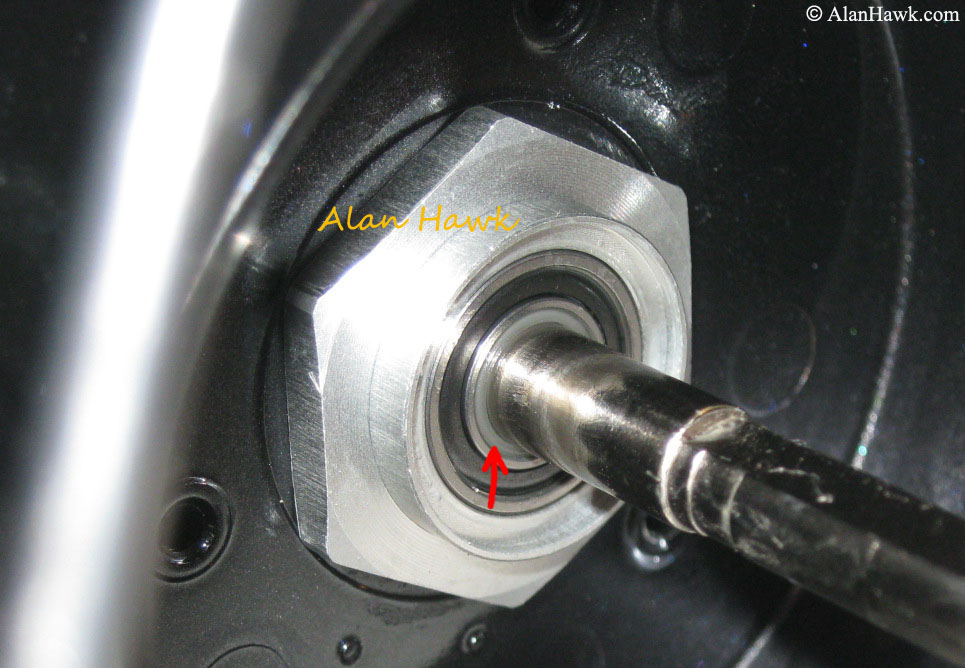

The rotor nut has a rubber seal (red arrow) beneath it which fits in a recess in the rotor (blue arrow).

The rotor of the new Stella is aluminium, and I can say that it's slightly more rigid than the rotor of the old Stella. Saltiga's plastic rotor with its excessive flexing isn't even close to being a match.

To reduce the reel's weight the rotor flanges are made of two plastic strips extending all the way to the top of the rotor arms. The photo above shows one of them removed. I criticised a similar use of plastic in the old Stella, and I'm still not happy with it. While it's quite resilient and does the job, it gives the rotor a certain feel of flimsiness and makes a cheap hollow sound when touched.

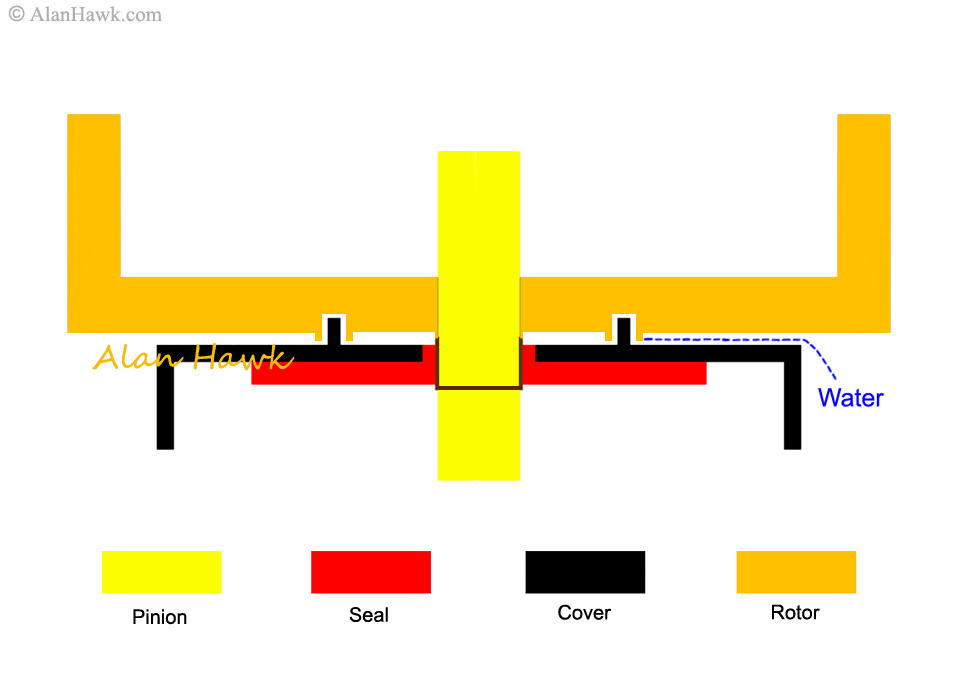

An innovative feature here is what I'd call the water wall. The pinion assembly cover has a circular lip (red arrow) which fits into the channel (blue X) moulded into the back of the rotor. This very simplified diagram should explain how it works

With the lip sitting inside the channel as per the diagram, water will have to do some acrobats to get past it. This barrier should be sufficient enough to stop water coming from gunnel splashes and even tap rinsing.

The cap itself has an O ring seal (red arrow).

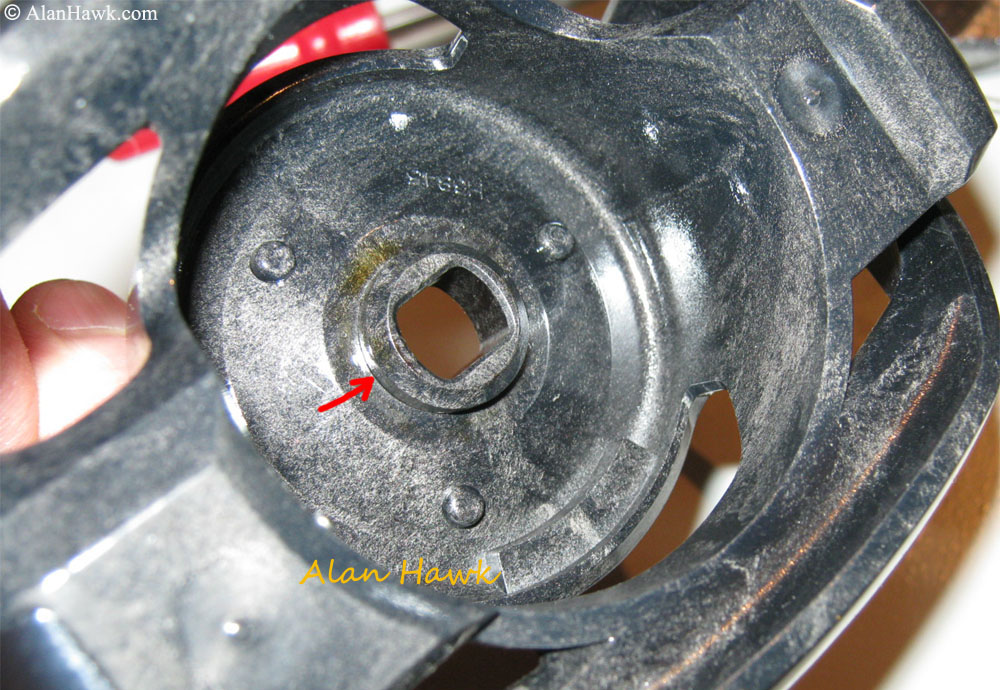

This is the main clutch/pinion seal, made of two parts; the body of the seal (blue X), and the pinion cup (red X).

Here it is out

The red arrow points a raised rubber lip that goes around the centre of the seal but touches nothing.

The cup removed

Actually it's a 4 stage seal. The red arrow points the rubber lip from the previous photo which would stop small amounts of water seeping in. After that comes the second stage, which is a another lip (blue arrow) securely wrapped around the cup, and this should stop water even if the reel was submerged. Assuming that by some miracle some water got past the previous lip, a small reservoir filled with grease (yellow X) should stop anything. And finally the fourth stage is the final lip (green arrow) also tightly wrapped around the cup. So the water that would get behind the metal "water wall" should then find a way to get past this 4 stage seal, which is simply impossible. Not only is it an impregnable barrier, but the grease trapped between the lips should reduce wear in the lips and dramatically reduce friction as well. This is easily the best and most advanced seal ever used in a spinning reel, far more effective than the beefy seals of the ZB and VS as well as being incredibly low friction and self lubricating for longevity. Comparisons with Saltiga's magnetic fluid seal is cruel but I have to do it; in Stella's seal nothing splatters and leaks into the clutch, you don't need to get a special fluid that's near impossible to obtain to service it, and instead of a vulnerable fluid being the first line of defence facing the elements and particles suspended in the water, Stella's seal has actual rubber lips to do that. Told you it was cruel! If you ever service a new Stella note that the centre cup must be inserted from the back of the seal because it would never fit from the front.

The rotor's neck has an O ring seal where it meets the centre cup of the main seal for perfect waterproofing. This O ring fits into a recess for reliability.

I mentioned the recess because the rotor's neck of the big Saltigas (6000/6500/Dogfight) has no such recess as seen in the photo above. You just drop the O ring in the pinion cup then get on your knees and pray that when the rotor neck comes down the O ring would fit vaguely correct. Being a non-religious person you can see how it's impossible for me to install it right. The smaller Saltigas though have a recess in this area.

This is the clutch itself. A reliable design that first appeared in the 2001 Stella (known as FA internationally), continued into the 2008 generation, and now the exact same part carries on to appear in the 2013 models.

Beneath the clutch I spotted this!

A hair. A bloody hair!! I was wishing it was a piece of fibre or something, but under the magnifying glass I could see that it's indeed a hair with the bulb and all. Well, hair grosses me out whether it's in my food or my reel. While removing this thing I tried to convince myself that it could be the pubic hair of a cute Japanese girl to make the job easier, but the logic centres in my brain kept saying that it's not very likely that Shimano reels are assembled by a bunch of frolicking naked ladies, so that mental image never worked.

Now I was about to examine the main ball bearing, and I was eagerly looking forward to this. Why? Well, right out of the box I could notice that the rotor of the Stella had side to side play. We're talking a very small amount of play here, but it was definitely not right. Watch this video, and look at the bail wire or the bail arm to better spot the play

I nearly lost mind and went through many of my other reels hoping that I would find a similar play in them that I somehow missed before, so it would mean that my beautiful Stella didn't have an issue; Accurate Twin Spin 30 and 30L no play. Catalina 6500H and 5000 nope. Saltiga 5000 and 6500H nothing. Torque 7 and 9 zero. I then checked lower grade reels; VM150, new and old Cabos, various Okumas, Two Ticas, Omotos, all the way down to a Sargus and a Battle, still no reel had such play. I then eyed my pile of crappy blank OEM Chinese reels but didn't dare to check because the potential result would have broken my heart. I then decided to forget about it and go ahead with testing, but during the many hours of fishing I always had that issue in the back of my head and hoped that miraculously there would be a good explanation. Now it was the moment of truth as I examined the main bearing

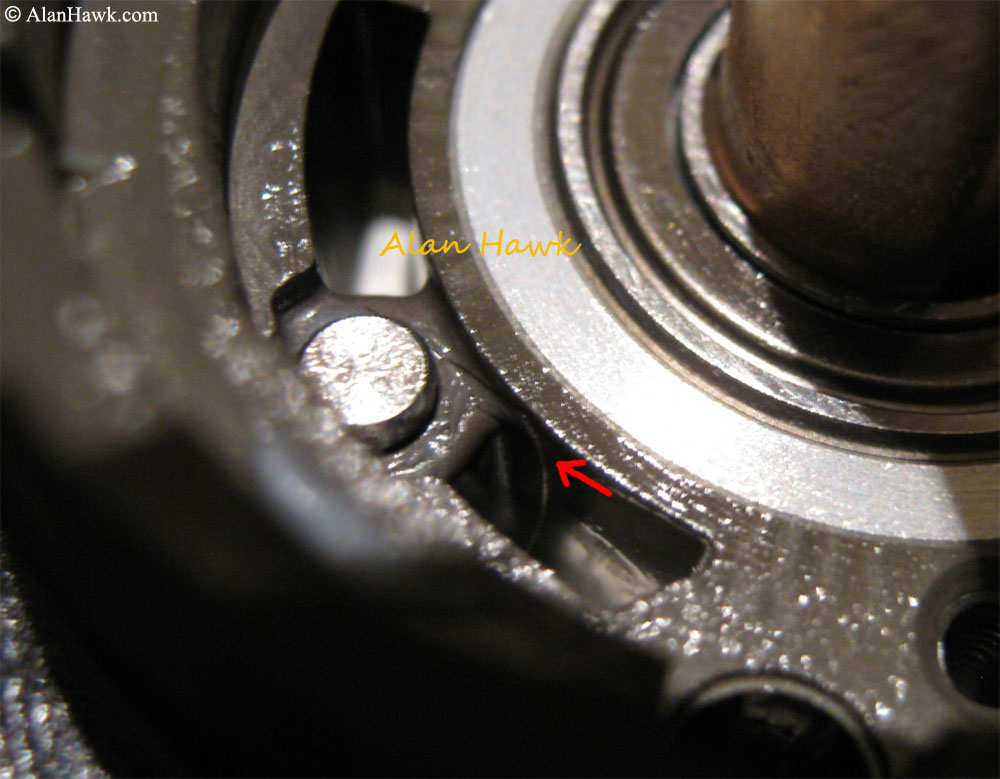

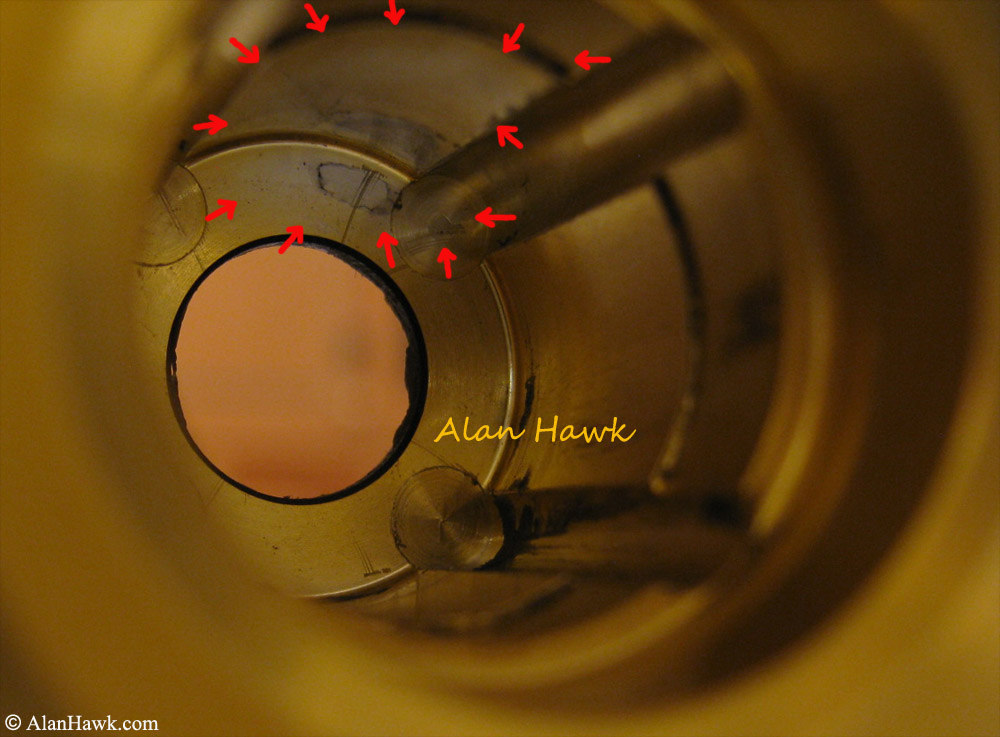

It's basically three parts here. The ball bearing (blue X), the bearing housing (red X), and the body of the reel (green X). The pinion fits perfectly in the bearing, but when pushed I could see there was a play between the ball bearing and the housing, and another play between the housing and the body, about 3/4 of a millimetre of clearance each. The combined play of those loosely fitted parts manifested itself in the rotor side play that had been bugging me since unboxing the reel. These parts weren't the only poorly fitted ones in the reel. Do you remember the new synthetic washer they inserted around the shaft that I showed you earlier? Watch this video

Do you see the scary amount of play in both the shaft and the rotor together? Of course I caught the play in the shaft as well when I first held the reel, but I thought it was a by-product of the rotor issue. Now examining the reel I could see that it was a separate issue resulting from the poorly fitted synthetic shaft washer. If you have one get it now and try yourself with the rotor and shaft, then get your 2008 Stella and compare. The problem here is not just my feelings of disgust. When the pinion is this unstable the meshing with the drive gear would not be as precise and stable as it should, and the play in the shaft would go all the way back to the traverse block and oscillation mechanism for a similar result. Not that it would seriously affect longevity considering the amount of play, but it certainly has nothing to do with precision engineering or any sort of engineering for that matter. That was easily the most painful discovery I made in all my years doing this, and you know I have enough passion for reels to actually feel upset over such things.

Let's move on

The increase in the weight of the reel is due to several things, most prominent of which is the reinforced and strengthened body. The stem of the reel now has a lot of extra metal (circled) where there was air hidden beneath the rear plastic bumper in the old Stella, and the horizontal hole going through the base of the stem in the old Stella is also gone. That was the hole through which the rear bumper screw was unscrewed. It was replaced with this

With the rear bumper made much shorter, the opening for its screw is now located behind the rotor away from the stem. The green arrow points the plug sealing this opening.

The best way to remove the plug is a straightened hook.

Side cover

The side cover now has a seal that goes around its entire perimeter. The seal is oversized and poorly fitted as the circled areas illustrate. The body seal of the Saltiga, old and new, is perfect and always fits tightly. The blue arrow point to the protruding screw hole that I described as an abomination at the beginning of the review. They had to put it there because they wanted the screws to be outside of the seal perimeter. That's not really needed. Yes, theoretically water could get inside the gearbox through the screw holes if the screws weren't outside of the seal, but in practice that wouldn't happen unless the reel sinks very deep where water pressure is high enough to actually push water into the capillary spaces around the loctite treated screw threads. Still in the above photo, the drive gear ball bearings are now held down by 4 screws

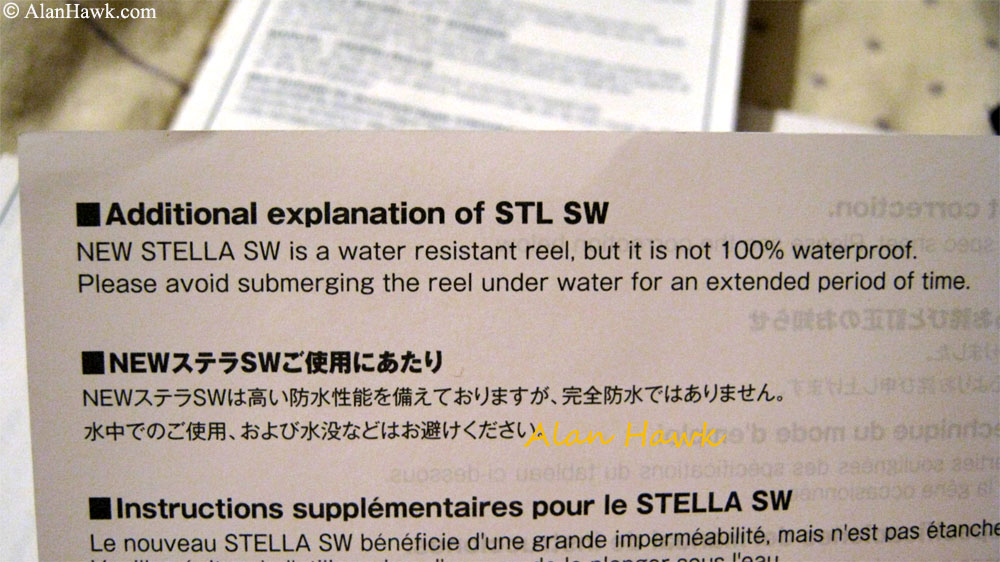

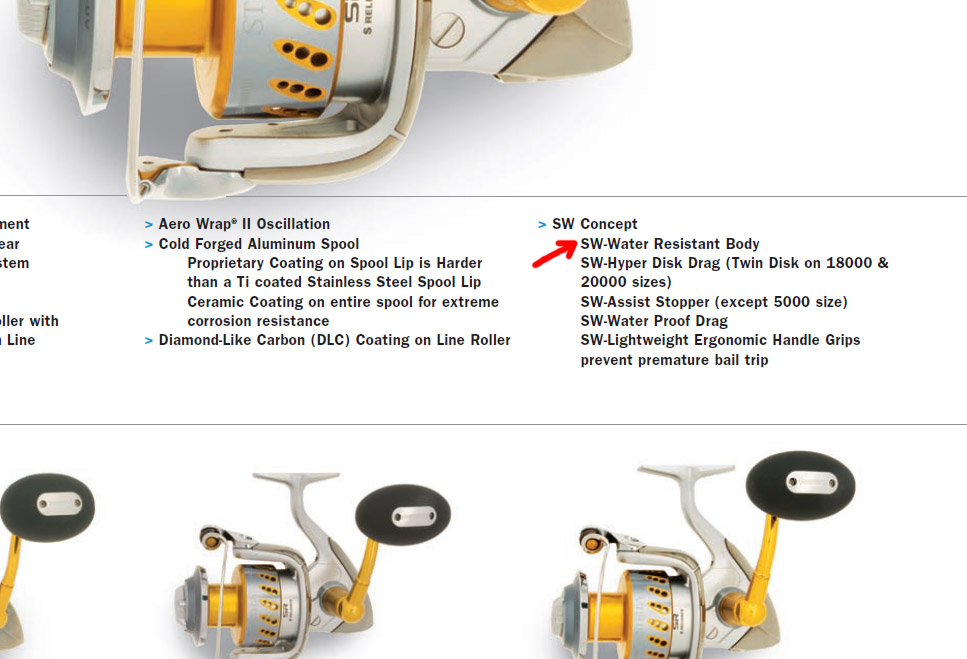

This is why. The sealing of the handle opening has now become a fixed seal (red arrow) beneath the bearing on each side, so the bearings need to be held down by screws in order to keep the seal pressed constantly for effective sealing. In the old Stella the handle opening seal was mounted on the handle itself so that it seals whichever side the handle was attached to, while the opposite side was sealed by the O ring in the hole cap. The old design was better because when you turned the handle you had resistance from only one seal (the one mounted on the handle). The new Stella has two fixed seals, one on each side beneath the bearing, so when you turn the handle the drive gear shaft will always face resistance by two seals instead of just one. Strangely this dual sealing was used in the 2001 Saltiga, then for the 2010 Saltiga Daiwa changed it to a system similar to that of the old Stella where you worked against only one seal. Now Stella drops that and copies the system of the old Saltiga! This dual seal is indeed more effective, but at the cost of the free spinning. It's the main reason why the new Stella doesn't spin as lightly as the previous model. The funny thing is that with all the annoying extra sealing Shimano says this

"Water resistant" but not "waterproof"? Really! But Shimano's catalogue said this about the old Stella

.

Water resistant as well! So why on earth would the new Stella have this complicated sealing and partially lose its trademark free spinning if they still warn us to treat it as a water resistant reel only? I did some crazy stuff with the old model and never had a drop of water inside the gearbox. Several of my readers also used the old one on the surf and had waves crashing on them, and through the service port they could see that no water got inside. Speaking of which, the service port is gone from the new Stella. It was one of the most useful features in previous generations of the SW since it's easily the most complicated series of spinning reels ever made and not many people can disassemble them for service. This reel makes less sense every second.

Close up on the handle opening seal

Continuing the theme of poor tolerances, the seal is smaller than the recess it fits in, so it has to be very carefully centred before the bearing is placed on top of it or else the sealing would be compromised. And guess what? Yeah, the ball bearing itself plays inside its oversized housing! At that point I should have vomited, but I had already gone numb and nothing seemed to really affect me anymore. The old Saltiga with this dual sealing system had seals that fitted to perfection into the recesses and the ball bearings did as well. The Stella of today has the problems that the Saltiga did not have 12 years ago. That's just beautiful.

Gearbox

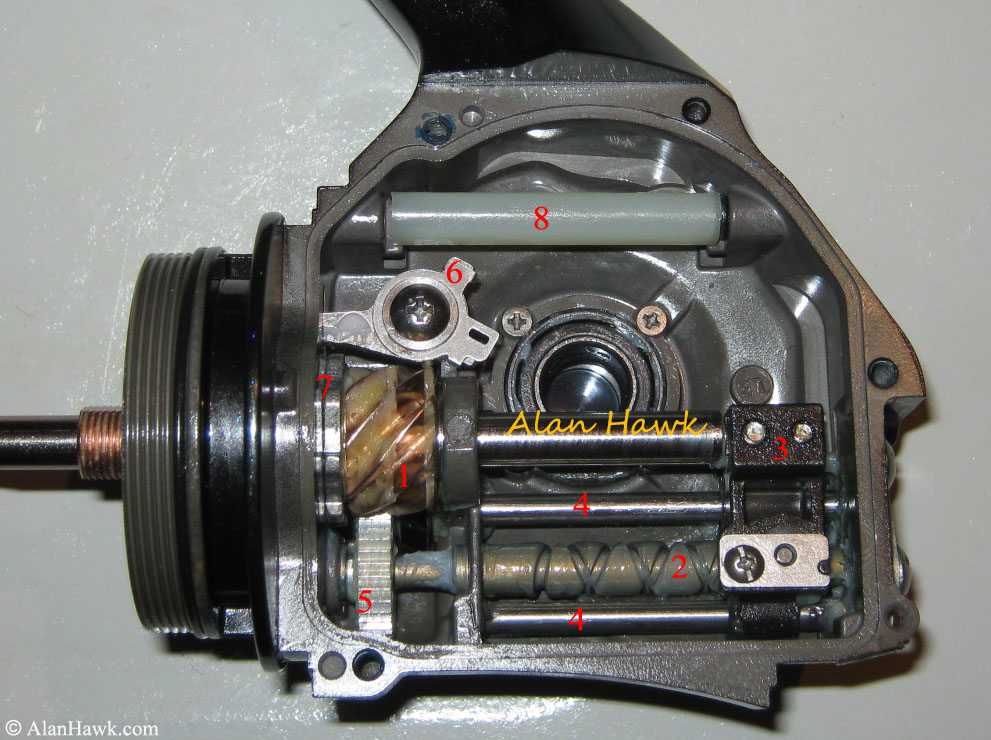

#1 is the pinion, #2 is the worm oscillation gear, #3 is the traverse block, #4 are the two stainless steel rods the traverse block rides on, #5 is the oscillation idle gear, #6 is the backup brake that engages the ratchet teeth (#7) in case of a slippage in the clutch, and #8 is a plastic tube for the screw holding the rear bumper.

Close up on the tube

There is an O ring seal at its right end, and the left end is sealed by the long plug which I removed earlier using the straightened hook.

Next to the idle gear I spotted something

Another hair! Are you friggin kidding me? Am I on candid camera? What is it that I'm going to find next, fingernail clippings? I've seen reels with all sorts of issues, but never seen a hairy reel before!

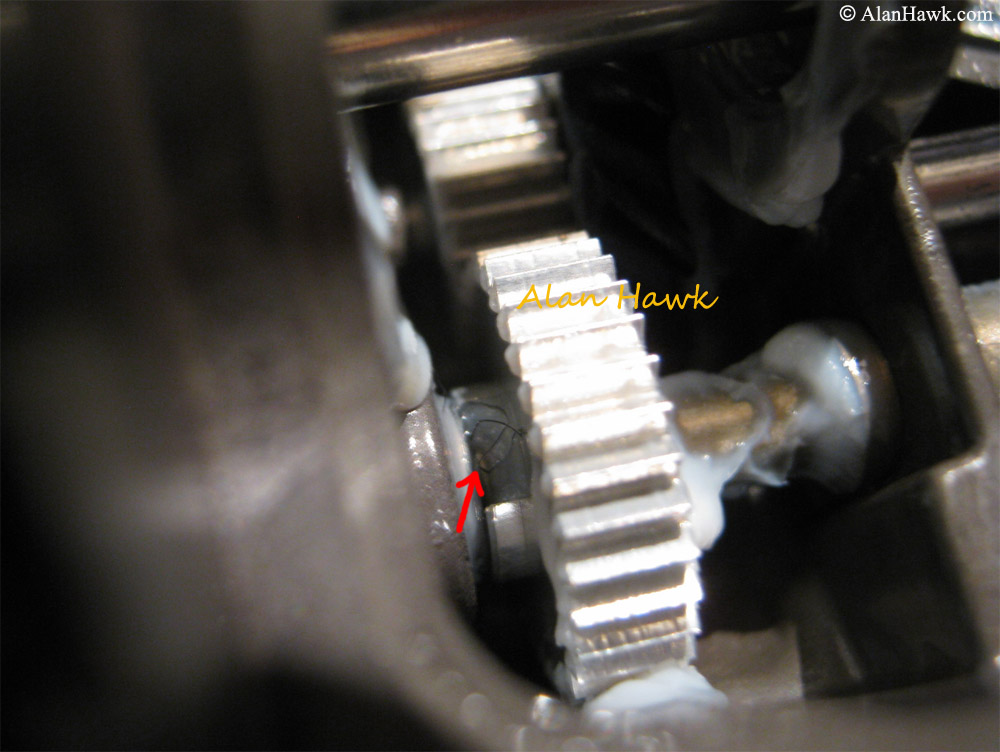

The pinion:

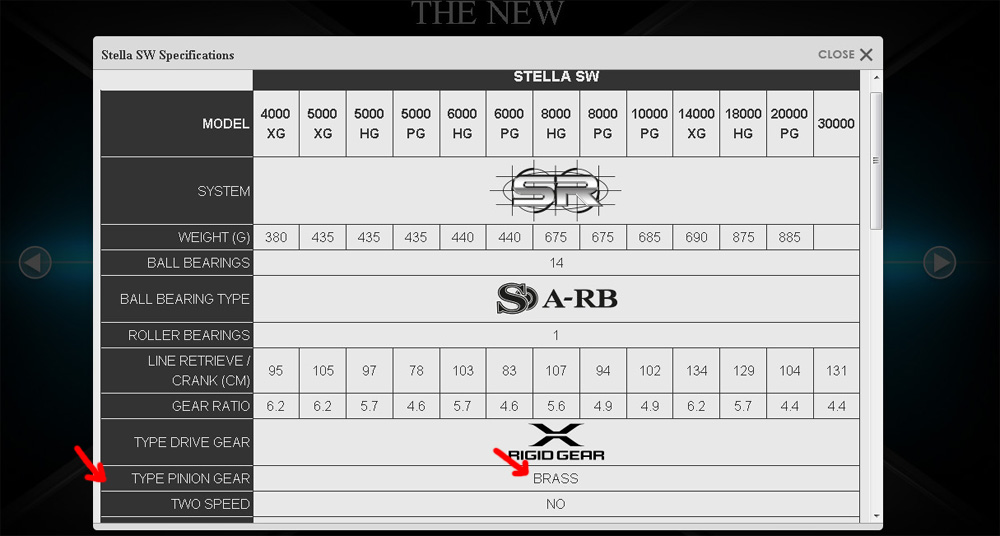

Back in February I had a friend in Osaka's show who was sending me news. He saw a cutaway Stella and told me that he thinks the pinion was brass. I told him to ask someone the following day to confirm, and he did and said brass. That didn't make sense to me. I knew that the last Stella SW to have a brass pinion was the 2001 model (FA) and that Shimano has since moved up to stainless steel in the 2008 reel, so I assumed that something was lost in translation and that it was a hardened stainless steel pinion since the colour of steel changes when it's heat treated. Then I saw this this on the first version of Shimano's own site called "What is Project SW"

Even after getting it from two different official sources, I still thought someone must have got it wrong and that it's in reality a treated stainless steel.

Nope, it's brass indeed. Shimano actually downgraded to brass. Examining the wear there is no doubt in my mind that it's nowhere near as durable as the brilliant stainless steel pinion of the 2008 Stella. The way I evaluate wear is by visually inspecting the wear pattern then relative to the use I put the reel through I would determine the wear rate of the gear. There isn't anything scientific about this and it's just me and my eyes, so take it for what it's worth. This brass alloy is certainly a good one, but it's not in the same league as the very tough stainless pinion of the 2008 reel.

The drive gear:

The drive gear is still the cold forged aluminium alloy of the previous generation, but they increased the thickness of the gear plate quite a bit. The diameter of the gear remained the same though, except for the new 14000XG model which has a wider gear than other reels in this size class to generate the very high gear ratio.

The increased thickness of the gear plate makes it more rigid, but it doesn't change the durability or strength of the teeth. The wear rate of this gear isn't different than the drive gear of the old Stella.

I spotted rounded tips though which could be caused by the side play in the pinion discussed earlier, but there isn't a way to tell for sure. The old Stella didn't show this sort of wear, even ones used for much longer.

This discolouration and darkened spots is a by-product of the finishing process that's quite common in all Stella models with this type of gear finish such as the 2007 (FD) and 2010 (FE) freshwater Stellas, and the 2008 SW. It's harmless, though this is the first time I see it on the teeth themselves. Knowing what effect this could have would need time and more use and examination, but let's agree that it would be safer and better if the finish on the teeth remained even and consistent without such irregularities.

The retainer plate of the worm oscillation gear (red X) is now a single thick piece instead of two thinner ones in the previous generation. A seal (blue X) makes sure that no water is getting in through these openings.

The oscillation gear, idle gear, and the two tiny ball bearings they run on.

The traverse block houses the same parts as the 2008 reel, except for the spacer that's pointed by the blue arrow which is now synthetic instead of metal. The pawl (red arrow) is one of the most stressed parts in the reel, and admirably it shows zero wear. No one builds a worm gear oscillation system better than Shimano.

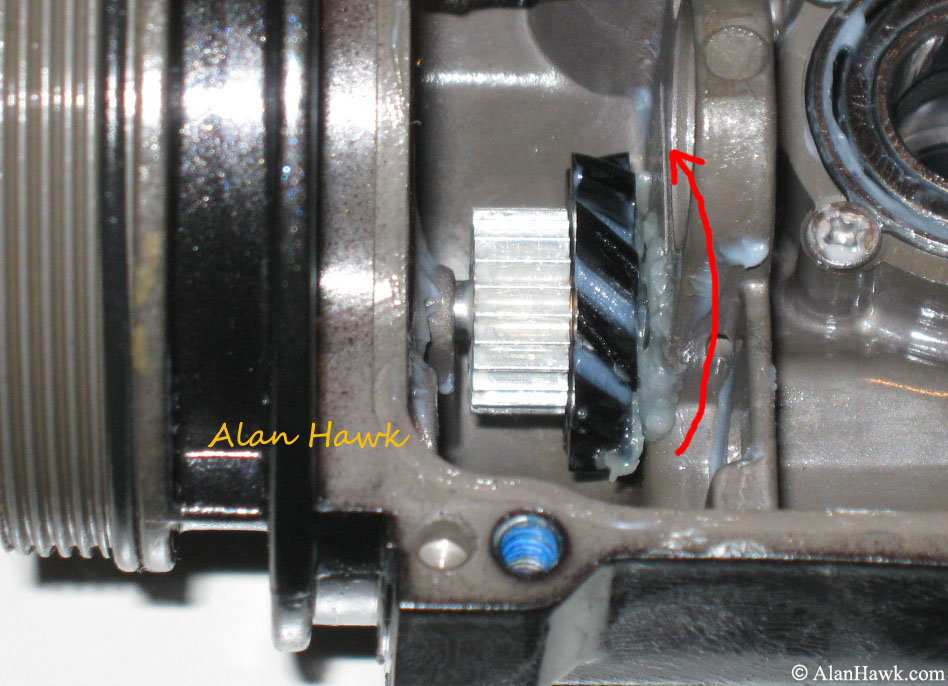

These are the hidden components of the oscillation system. In the previous Stella the pinion directly turned the idle gear attached to the worm shaft, but in this new setup the pinion turns the black gear in the direction of the red arrow, then the silver gear transmits the movement to the idle gear and worm shaft. This setup slightly slows down the movement of the spool up and down making the line lay on the spool in closer coils, and it transmits more torque to the worm shaft. This setup has nothing to do with the super slow oscillation of the 2001 reel (FA), rather it's nearly identical to the one used in the 2004 freshwater Stella (known as FB internationally).

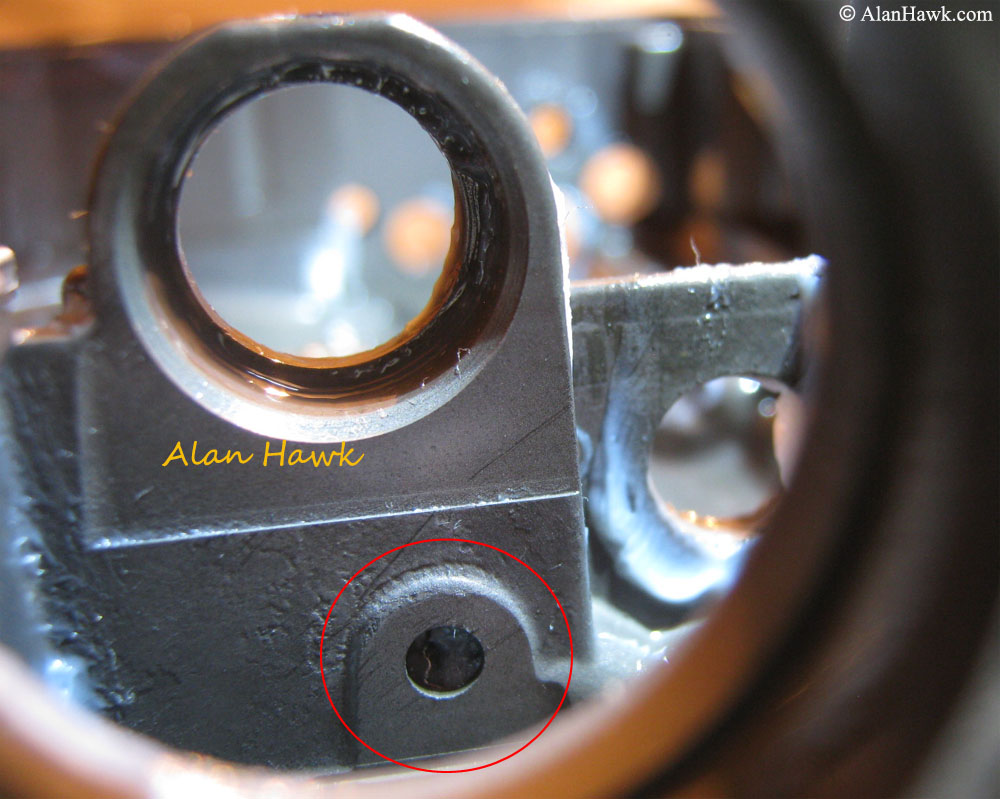

The two gears taken out, and their axle can be seen in the background. When the black gear gets turned by the pinion in the direction marked in the previous photo, it also gets pushed to the right as well due to the angle of the teeth. The more load the reel gets under, the harder this black gear will be pushed to the right. As this happens, that little raised part of the gear (red X) rubs against the body of the reel

Here is the area where the gear rubs (circled). I couldn't capture the rubbing marks on this part of the body because the camera lenses can't get close enough to this protected spot, but the marks are there (I don't mean the diagonal scratches which are most likely tool marks). The black alloy gear should not have been left to rub directly against the body of the reel like that. At the very least a bronze bushing should have been inserted in the wall to reduce friction and protect the body of the reel. Shimano perfectly understand this since in the 2004 freshwater Stellas they did put a low friction bushing between the gear and the body of the reel. This might sound insignificant, but it's a replication of the infamous design flaw in the 2001 and 2010 Saltigas where the oscillation gear sands off the body

Kinda invalidates the concept of multi bearings. If it's tolerable that the black gear in the new Stella would have this kind of friction with the body, why bother installing tiny bearings in other places where the friction of bare metal would be about the same? Also it's normal that replaceable moving parts would wear over time, but it's not right that a part would cause wear in the frame of the reel.

Anyhow

The extra reinforcement of the stem, the body that's made wider to accommodate the wider drive gear, and the 3 added oscillation parts are the main cause for the weight increase. Actually it should have been even heavier had they not taken drastic measures, such as this

The front cap of the spool (red X) is now made of plastic in all sizes expect the 30K. It used to be metal in all previous Stella generations. It is indeed a non-operational part, but it feels super cheap and flimsy to the touch, and that plastic flexes easily when pressed.

This is my stickbait hitting the water during a cast. I really wanted you to see this so I had someone take a dozen of photos as I made casts until the impact moment was captured. Let me put it in a very few words: with the exception of dedicated long cast surf and competition reels, the new Stella is the farthest casting reel I have used in my life. Granted that when I threw poppers I had on spool the best casting braid money can buy, Sunline monster battle, still I have fished the old Stella with a variety of lines long enough to tell that there is a difference. I am comfortable saying that the new reel casts about 10% farther. The oscillation has something to do with it and maybe even the new coating on the lip, but I believe it's mostly due to the changed angle of the reel's foot. When the new Stella is mounted on a rod the shaft is almost parallel to the rod instead of pointing up as the previous model did.

Not sure if that's something I can capture in photos, but that new foot angle makes line go through the guides in a way that feels more natural and intuitive. When I cast I hear less flapping as the line passes through the guides, and when landing a fish I could sense less friction between the line and the first ring.

The bail mechanism is slightly altered because the rotor arm is now split. The split looks nice and all, but it limits space and prevents the spring's sleeve from moving, so the bail action feels weird. It opens nicely, but when it's being closed it moves smoothly for a short distance then it suddenly hits a lot of resistance at the toggle point, and extra force is required to push it past that point so it could snap closed. The resistance at that toggle point is so high it feels as if the bail has hit a stop, and it needs some getting used to because giving it the usual quick flip to close won't work. It has to be pushed hard past that toggle point. The bail wire is now made of titanium, and the bend in the bail (circled) is less sharp than the bend in the old reel. Still in the above photo, the bail arm (red X) has been redesigned, and a synthetic bushing is inserted between the screw and the arm (red arrow) for a smoother operation.

Unacceptable amount of clearance between the bail arm and the rotor. Makes the bail arm a bit unstable.

The other end of the bail wire has a plastic bushing (red arrow) identical to the one at the joint of the the bail arm.

The line roller screw is masterfully secured with a stop plate held down by a little screw.

Disassembled. Love the engineering and execution.

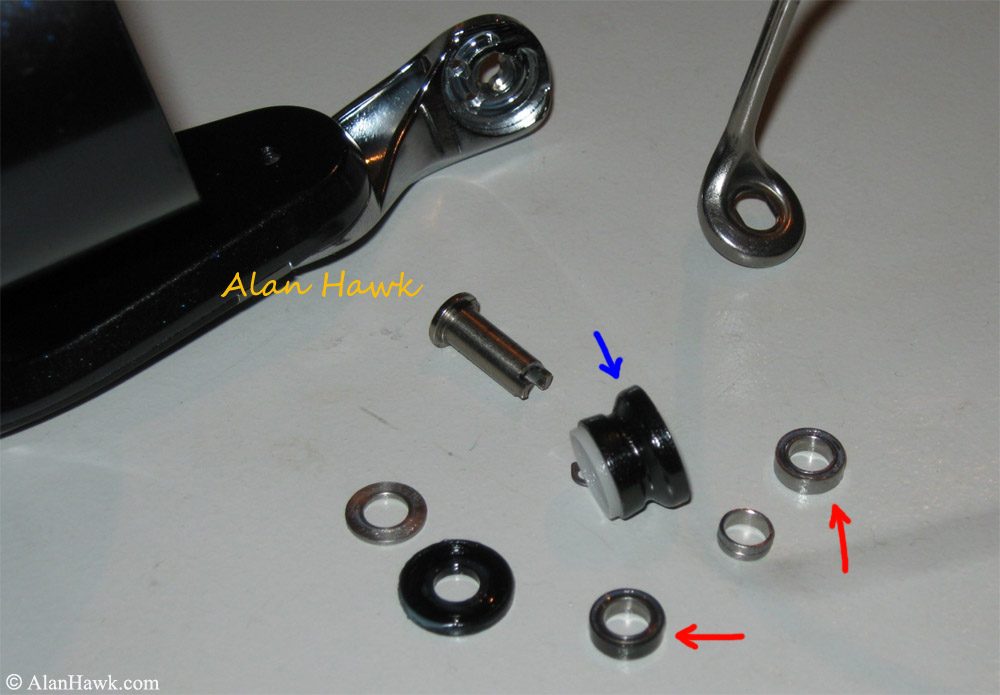

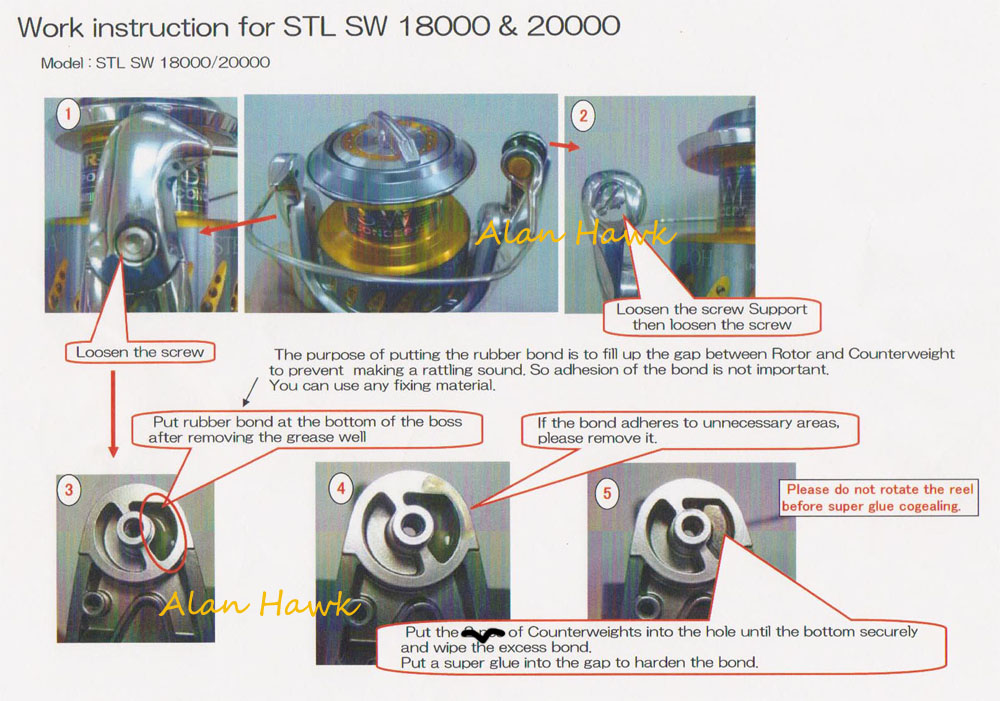

The line roller assembly. It has two ball bearings (red arrows), and the line roller itself (blue arrow) has a story; the early 2008 Stellas had problematic line rollers which developed corrosion underneath the finish, chipping that finish and causing line damage. This happened in probably 2 out of every 5 early Stellas. Shimano issued a recall in Japan in October 2009 and asked people to send their reels back for repairs, while they sent their international representatives replacement rollers, balancers, and a double sheet of instructions for installing them

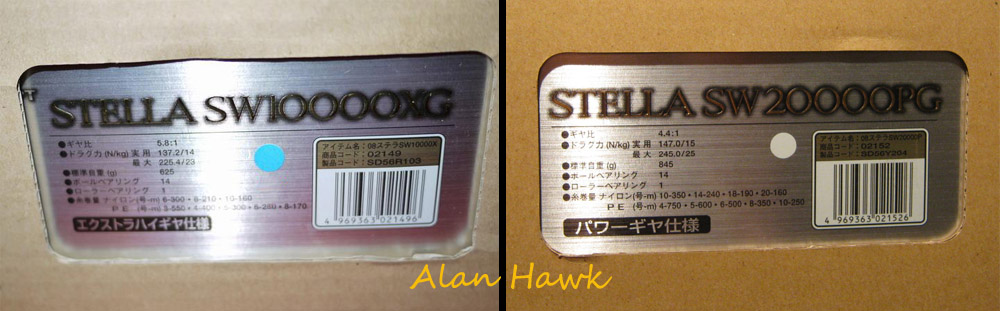

The balancer was needed because the new roller was 1 gram heavier than the old roller, so a counterweight needed to be glued to the opposite end of the rotor to keep it balanced. They then started putting a blue sticker on already manufactured reels that they updated, and newly produced updated reels would have a printed silver dot on the box

Here they are. They also put a little silver sticker on the foot of the updated reels. The replacement roller has been tested and proven trouble free since 2009, so there should be no worry about that happening in the new Stella since it has a line roller made to the updated and tested specifications. I am saying this in response to one of the questions I received a lot from people who heard about the old roller problems and were wondering about the new Stella.

New handle design.

The knobs are interchangeable with the 2008 Stella, and the egg shaped ones are identical to the ones in that 2008 model.

The threaded shaft is hollowed out to save weight. This is a very strong part. At the end of my tests I purposely tried to strip the threads by screwing the handle into a long nut held in a vice but couldn't, and since I bench press 150kg on a bad day I kinda think the threads will be just fine.

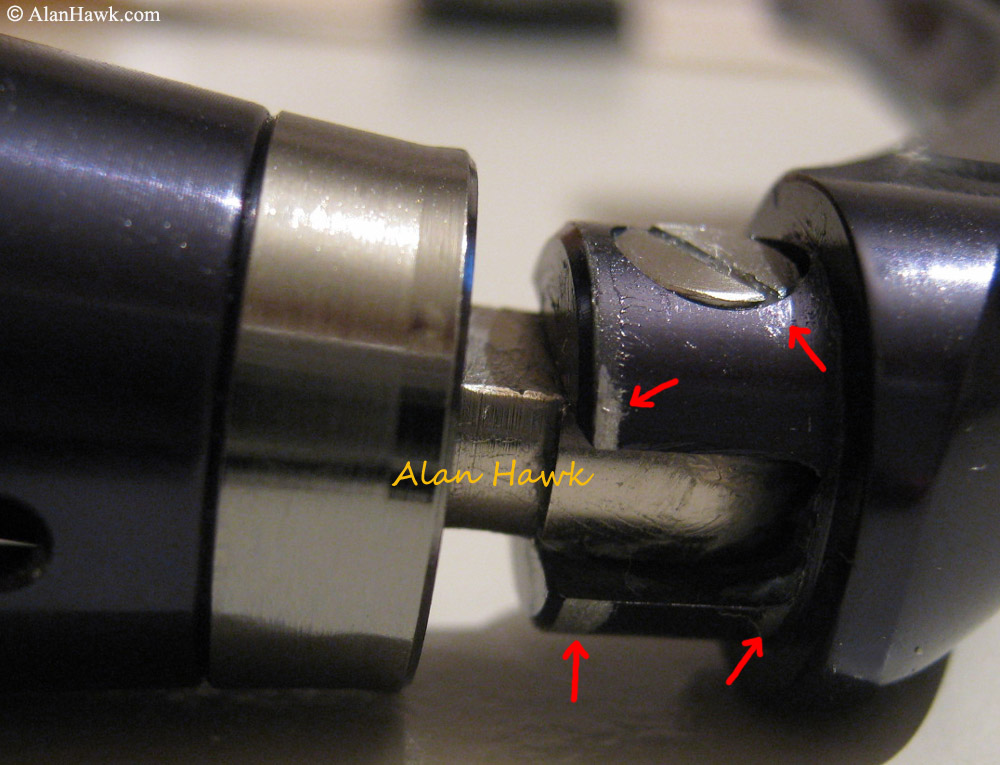

The sleeve (red X) is unscrewed to expose the shaft (red arrow) in order to exchange it with the spare shaft for right hand winding (sizes 8000 and up only). My main interest though is the split joint (blue X).

The sleeve has a stainless steel tube (red X) that encases the joint (blue X), supposedly to reinforce it. The problem is that the stainless tube is wider than the joint and doesn't really do anything for it. This is not a bad manufacturing tolerance, but rather it was designed like this and you could feel the space between the joint and the stainless tube. Had the tube fitted tightly around the split joint it would have supported it and increased its strength tangibly. I'm not saying that the joint is weak, after all it survived my attempt to break the threads, but just saying that when they tell us that this steel tube somehow supports the joint or eliminates energy loss caused by flexing it simply isn't true. It does nothing.

Did I say that the tube does nothing? Actually there is something that it does. It damages and removes the finish of the joint! You see, this part was originally finished for a reason, which is to prevent corrosion. And while in some special cases it might be acceptable that over many years of use the finish of some parts would show some wear, it definitely is unacceptable for the joint finish to get severely damaged beginning with the very first use! The handle doesn't fold and must be taken off for transportation, and every time you install the handle there bound to be friction as the steel tube slides on the joint while you tighten the handle. You will see the finish beginning to go on the first use, and in a very short while it will look something like mine.

Since we're talking about finish issues

The wall and bottom of the drag stack tube have large areas that weren't anodised correctly. The metal is bare in a a large area of the wall, and the bottom has that weird looking finish flaw. This is a manufacturing defect, not something that happened with use, particularly that the bottom is protected by an eared tube shielding it from any friction.

The coating on the spool also developed those spots after some use. I rinse my reels very well at the end of every day, I never store reels with line on, and spools get special attention and lubing after each fishing trip. The spool developed these in about three or four places.

Let me put it all in perspective. The reel is immensely strong. They went for maximum rigidity as a design concept and this was undoubtedly achieved. I jigged, popped, trolled, and live baited, and landed a combined total of roughly 2.5 tons of hard fighting pelagic fish, including BFT up to an estimated 180lb, without a problem. The reliability is unquestionable and I can't see them failing on fish. When testing a Stella or a Saltiga though you aren't realistically expecting a failure, rather it's about checking the ergonomics, quality of manufacture, resistance to elements, and seeing if the expected longevity corresponds to the extremely high cost. Overall, the improvements in the 2013 Stella SW are casting distance, stronger body, smoother drag, and relatively better looks save for the fat gearbox. On the downside though it has more plastic inside and out, big play in the shaft, it's tighter to spin due to seals even though they still tell us it's not waterproof, has downgraded gearing, bail closure is counter intuitive, the very useful service port is gone, and now it has become one of the heaviest spinning reels in production surpassing even the hefty Penn Torque 9.

That's all. I have a considerable disposable income and the price of a reel was never an issue for me, yet I can't help but feel a little bit of anger when I look at the reel. When I spend thirteen hundred dollars on a reel I might not have an automatic right to expect a new world's best, but I think that I have every right to expect a reel without patchy spool anodising, side play in the rotor, spots appearing in the spool coating, and a finish that peels off the handle joint as soon as it's used. The fact that this is a "Stella" adds some sense of betrayal as well. That's a prestigious name of which I expect a lot, but I didn't get even the bare minimum, hence the feeling that I got cheated out of my money. When I tested the 2008 Stella I wrote a review that was a virtual love poem and put it on top of my "Finest Offshore Reels in the World" list for years, but sadly the new reel won't even make the list. I'm not a fanboy nor do I have any brand loyalty. My only loyalty is to my fellow anglers and quality is where I find it, and I certainly didn't find enough of it here.

The review is finished, but need to give you a quick heads up. If you have been following my work over the past decade you'd know that a negative review is almost always guaranteed to send people into total hysteria. While there is no justification for acting like a twat, I certainly can understand why they do it since a lot of money is invested by companies, dealers, and retailer, and they would sink as low as it takes to counter negative reports. It used to be only the garage operations who act like fools in response to my reviews, but sadly it also happened more than once with mainstream brands that I used to think were better than this. So, there is a chance that you'll hear things such as I'm being secretly paid by Daiwa, sponsored people saying that the reel is the best thing since flavoured condoms, see a sharp increase in vocal "happy customers" who own the reel and find it to be perfect, someone recognises "special markings" inside my Stella and identifies it as a prototype or a sample that was sold to me by mistake, spineless cowardly Facebook shills saying that I test reels by smashing them on the floor, or imbecile self-proclaimed gurus posting many diagrams explaining why I'm wrong. I usually smack those people down with facts and refute their rubbish, but this time I won't bother as I have a big family event coming up and need some time to relax and tend to other things. I'm leaving this job to you. If someone starts posting dodgy rubbish, speak up and tell them it has all been done before and make sure no one gets fooled. I sure hope there will be no such things, but I have seen enough to make me except the unexpected from anyone.

I'm not sure what my next review will be or when, but keep your eyes on the news page for updates on what exactly I'm going to do.

Hope you've enjoyed this.

Cheers

Was this a good read? Please click here

Alan Hawk

July, 8th, 2013

UPDATE: Following this review Shimano acknowledged the existence of the problems and said my review was being studied in Japan to address them. Click HERE to see Shimano's statement. Eventually I verified that some improvements were indeed made that partially addressed some issues; play in the rotor has been dramatically reduced, spool finish imperfections are gone, and the seals now fit considerably better.

|