Daiwa Saltiga 2010 : The Review

Hello again,

Last year I thoroughly tested then reviewed the Stella SW, and today it's time for Daiwa's response to Shimano's flagship reel. References to and comparisons with the Stella are inevitable as these two reels are always mentioned side by side whenever the very best in spinning gear is discussed, but I will try not to elaborate much on the Stella when it's mentioned not to make the review even longer, and you can refer to its own review here if you want to read more about it.

Before we proceed, I need to explain that I don't write magazine style reviews where they make a few casts and look at the reel externally, then based on the manufacturer's provided specifications tell you that the reel is durable and dependable with the single problem of it being "so pretty it's distracting" or similar. I test, pressure and push the reels, then I open them up and examine everything myself before presenting my findings as straight as they come. So if it gets too long or too technical for your taste, skip a paragraph and check the following one and eventually you will get the gist of it.

The new Saltiga is a dedicated saltwater big game spinning reel in three size groups. The 4500-5000 are the medium sized class, then there is the 3500-4000 size class which is smaller, and finally the big ones in 6500 size class to compete with Shimano's 18000 and 20000 Stella SW. The 5000 reviewed here is the 4.4:1 ratio version, and the 5.7:1 reel is called 5000H (high speed). The 4500 & 4500H have identical line capacity to Stella 8000SW, and the 5000 & 5000H have the same capacity as 10000SW.

I was more impressed than I have been in a long time when I first examined the Slatiga. I don't think there is much argument that it's one of the best looking reels in current production.

But it wasn't just looks that left me impressed. A few turns of the handle revealed surprising improvements over the old Saltiga. They obviously had Stella's free spinning in mind when they designed this reel, and they undoubtedly succeeded there as it was clear to me that the new Saltiga has a freer and easier spinning than the Stella. The difference is so subtle it's not easy for many to sense, but I did sense it, and it was even more impressive considering how tight the old Saltiga was in comparison. I will repeat myself here and mention that free spinning is always referred to as "smoothness", which is inaccurate. Free spinning is the lightness and fluidity in which the handle turns, while smoothness is the lack of gear noise and whirring during operation. Again, Saltiga wins hands down when it comes to smoothness; The SW is a quiet reel and gears hardly make a noise, but the new Saltiga manages to be even quieter and the gears mesh nearly silently. Again, the difference in smoothness is not much, but it's there and certainly in favour of the Saltiga.

The new Saltiga has a deeper spool than the old one, increasing line capacity considerably. I don't measure line capacity by breaking strength because that does not make sense, so I'll say instead that the new 4500 holds 320 yards of 0.013" line (300 meters of 0.33 mm line), and the 5000 holds 270 yards of 0.0145" line (250 meters of 0.37 mm line). An increase of roughly 25% from the old Saltiga. The weight of the reel has increased from the old Saltigas too.

They advertise the 5000 as weighting 21.1 oz (600 grams), but in reality it's half an ounce heavier at 21.6 (614 grams).

What comes with the reel

Unlike Shimano does with the Stella, Daiwa does not make a designated version for export, so the box has specifications printed in several languages, including English, in addition to Japanese. It also comes with 2 manuals, one in Japanese and one in English. There is also a bag of spool shims to adjust line lay according to the diameter of line used, a reel's bag, and they finally stopped putting the dumb line clip on the spool and now include an elastic spool band (red arrow) similar to the Stella. Well, everyone likes to save money, but Daiwa sometimes comes across as being a little cheap. This is why the bag is marked "Daiwa" only without a mention of "Saltiga", and the band has Daiwa's logo only without a mention of the model too. This makes it possible for them to use the same bag and band for other models as well. The bag and band of the Stella and marked "Stella". Also, the line band of the Stella has an integrated tongue to pull it off by, but Daiwa's band does not, which makes it a pain in the bum to try and pinch it in order to remove it.

The maximum drag of the 4500 & 5000 is 33lb (15kg). Less than the 50lb (23kg) of the Stella 8000 & 10000, but a significant increase from the old Saltiga that had a maximum drag of 22lb (10kg). Manufacturers generally claim unrealistic maximum drag figures; the drag washers might actually be able to produce the advertised number, but that does not mean that the reel can be fished at it. For example the old Saltiga 6500 had a drag rating of 66lb (30kg), but when I tested it myself the bail arm touched the spool at 45.2lb only (20.5kg), and when unloaded the bail arm did not revert to where it was, rather the entire rotor arm became permanently about 2 mm closer to the spool than it originally was. I will come back to the rotor of the new Saltiga later and tell you how much drag it actually handled.

Daiwa would not give away the magnetic oil they use, but I managed to secure some through my contacts in Japan. They claim that it's superior to commonly available types and specially formulated for longevity and elements resistance, but there is no way for me to verify this at the moment.

The drag

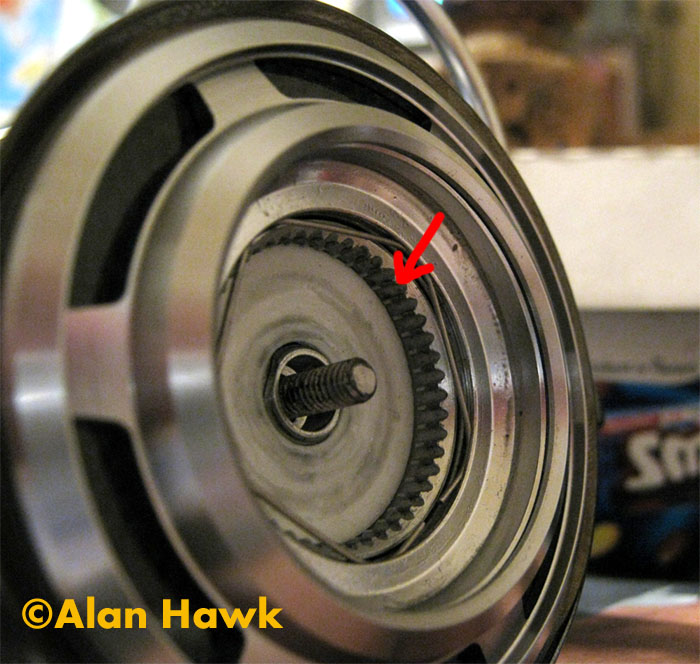

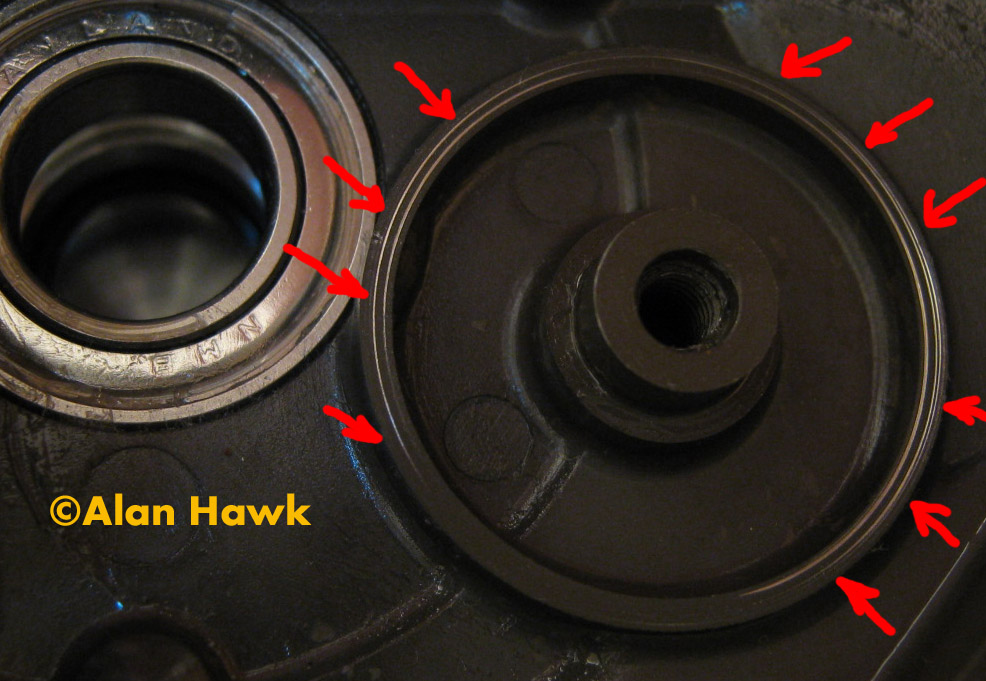

The drag stack has the same number and arrangement of washers as in the old Saltiga, but the washers' construction is different. The older ones were pure carbon that were brittle and had a sticky start up under high drag pressure, prompting those who went after big pelagic fish to replace them with Carbontex washers even before line was put on the reel. The new drag washer (red arrows) though is a woven carbon fibre that is extremely similar -if not identical- to washers made by Carbontex, and the performance is just as great. No startup spike of any kind, consistent and smooth, and the heat buildup is definitely less than the washers of the old Saltiga. One more thing I found was that the new washers are more durable, and unlike the old ones they don't shed particles creating that gummy residue you might be familiar with from the old model. That means longer life and less maintenance of the drag stack.

The drag knob

I certainly expected that they will follow Shimano's example and make a metal drag knob for the 2010 Saltiga, but they kept the plastic knob of the old model, marking it "Saltiga" this time.

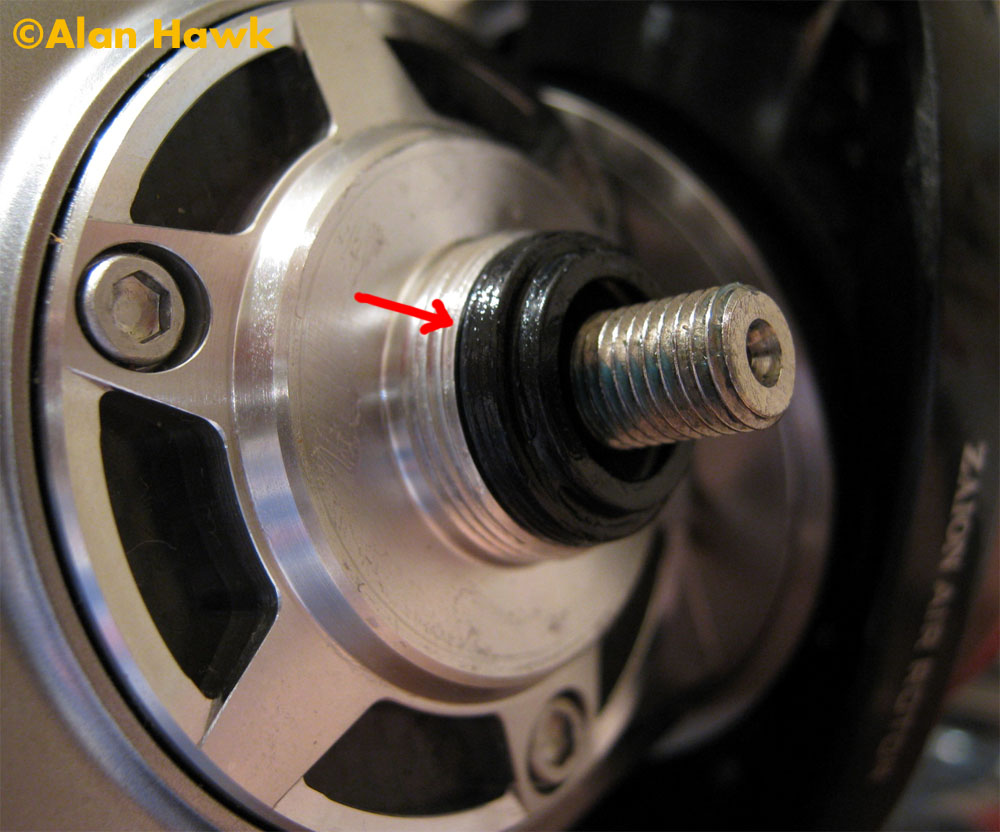

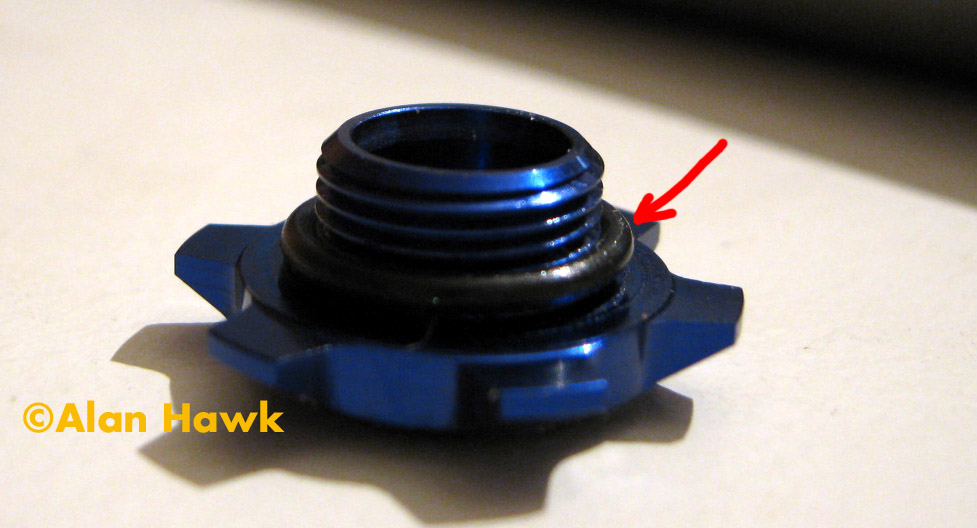

They did follow Shimano though in making the inner cap that touches the drag stack (1) of metal. Not that the old Saltiga suffered a melting problem, but with the increased maximum drag a metal cap sounds reasonable. Daiwa did not key the knob to the shaft as most spinning reels makers do today. Instead they stuck to their +17 years old design in which a metal spring (red arrow) double tasks as a knob clicker and a brake lever to keep the knob still as the spool spins and gives line. The round seal around the knob (2) keeps water out of the drag stack and it works just fine with the reel fully underwater.

The knob's clicker teeth

Let's have a very close look....

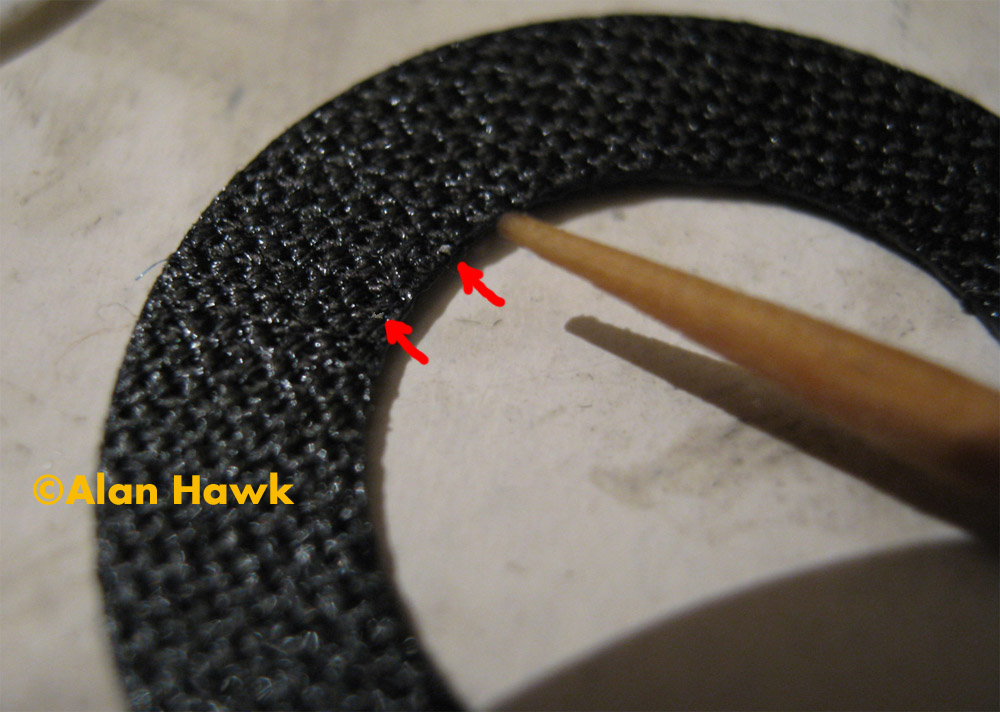

This clicker also comes straight from the old Saltiga, but for the 2010 model it has received shiny plating. Looks fine, but as the drag knob is turned, the metal spring (third pictures above) breaks off the plating layer leaving tiny metallic shavings (red arrows) around the teeth and further. The drag knob does not need to be used for a while for that to happen. Just turn the knob all the way and unscrew it all the way 2 times and that should do it!

Those metallic shavings stick to the shaft, among other parts, and as the spool is taken off and put on, the shavings get stuck to the drag washers (red arrows). Not that it would harm or affect the functioning of the drag or the reel, but it just feels too cheap and badly engineered for such a prestigious reel.

The drag runs on 2 ball bearings. I found the upper bearing to be an open type with no shields or seals. This is the only unprotected ball bearing in the whole reel. The drag is of course waterproof and this bearing is safe from exposure to saltwater, but still a cheap move to save what can't be more than $0.2 per reel! Seriously, what's the point? A shield would have been nice to keep the lubricant in good condition and to prevent the drag grease from getting inside and mixing in with the bearing's lubricant which is a different type of grease. Thankfully the drag washers do not leave residue or that open bearing would have gummed up.

To round up the drag

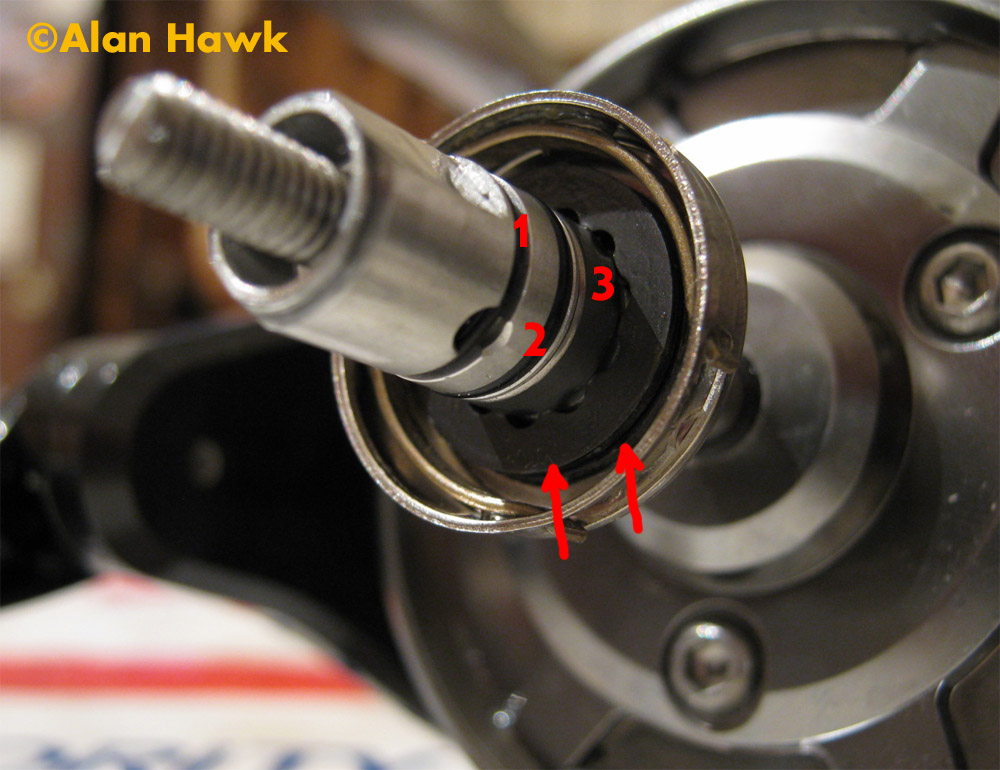

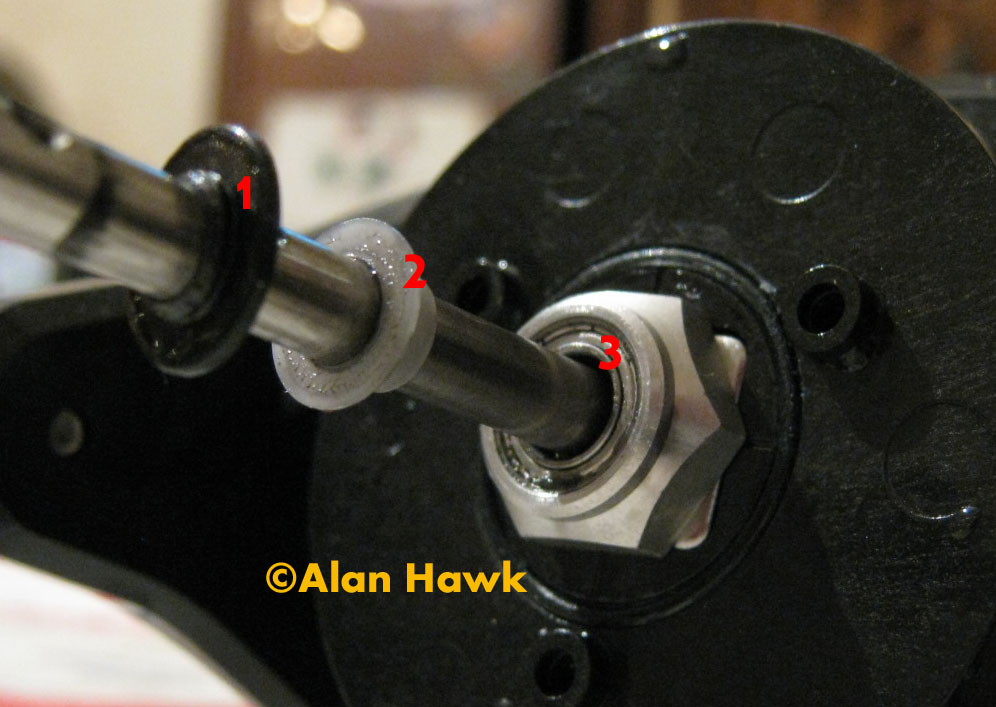

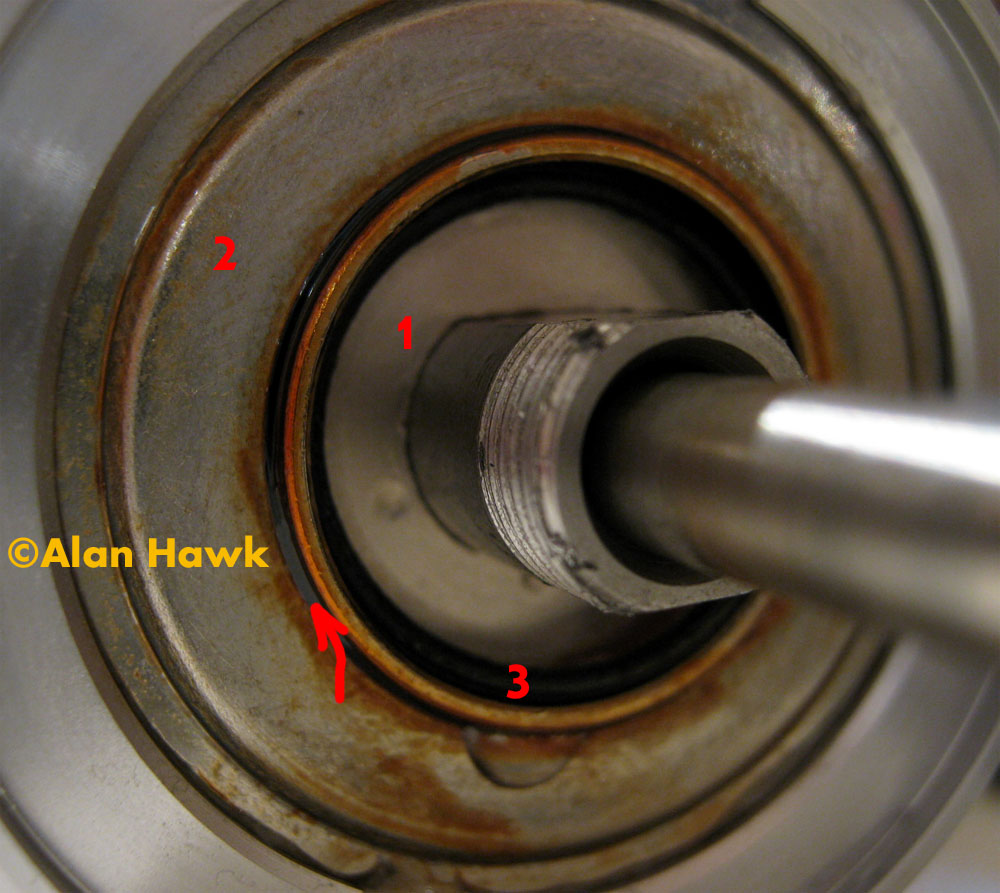

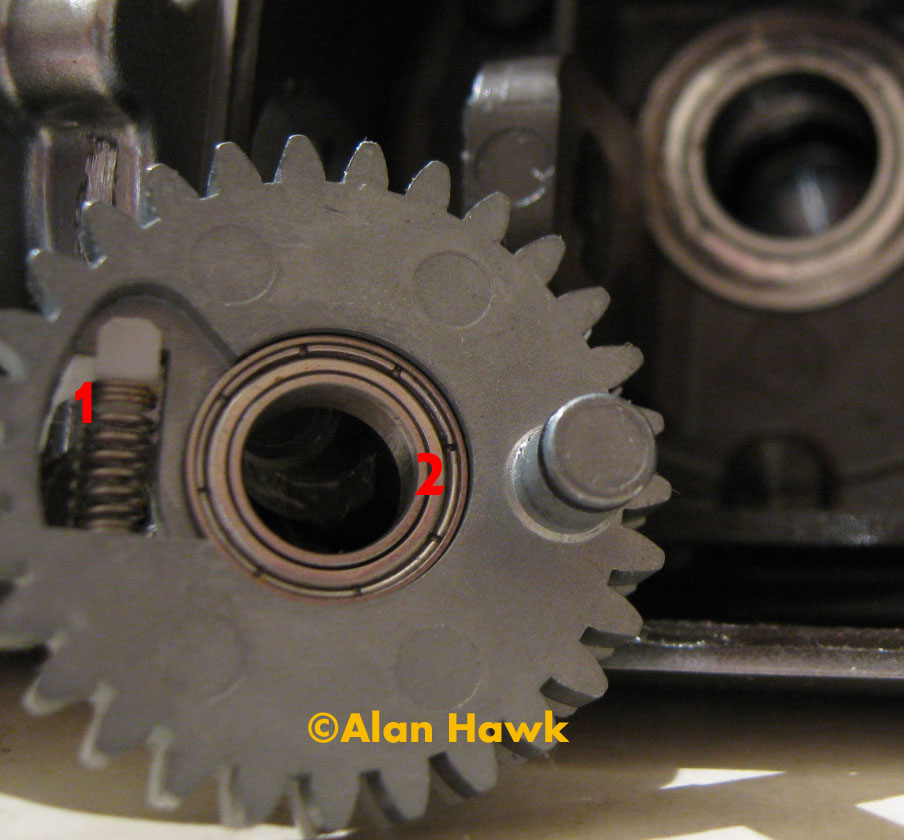

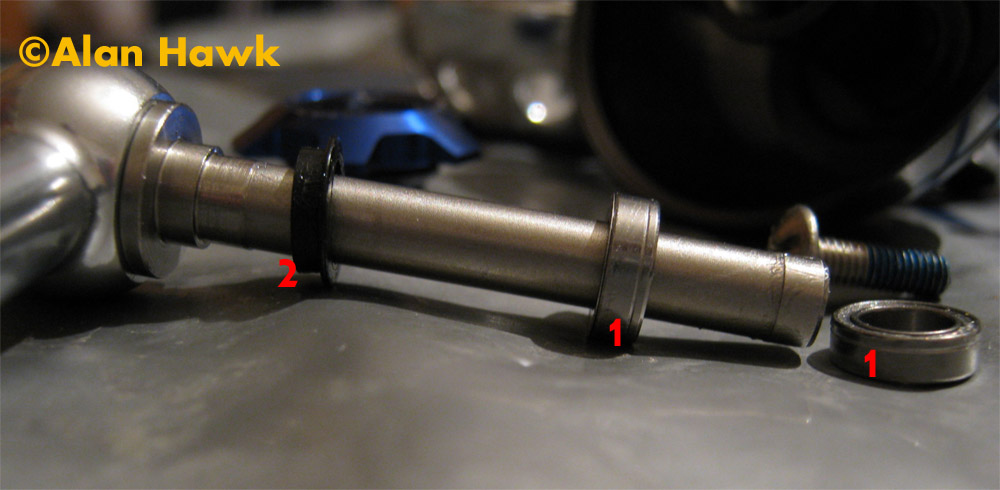

The spool hub and clicker designs have been taken directly from the old Saltiga, using the exact same parts. Here you can see the top O ring (1) which is used to keep the retaining pin in place, and bottom O ring (2) which is the very effective bottom seal of the spool. An advantage of the Stella SW design is that both spool's bearings are permanently inside the spool and protected by the spool's seals, while in the Saltiga the bottom bearing (3) stays on the shaft and the seal is above it, leaving the bearing exposed to saltwater if submersed.

My reel came with two spool shims (red arrows) installed. The two shims are required to have a level line lay on the spool. I removed one of them but the line took a conical shape on the spool packing on the front half of it, so I had to reinstall the second shim again. Why does the second shim bother me that much, you might ask? Take a deep breath and keep reading:

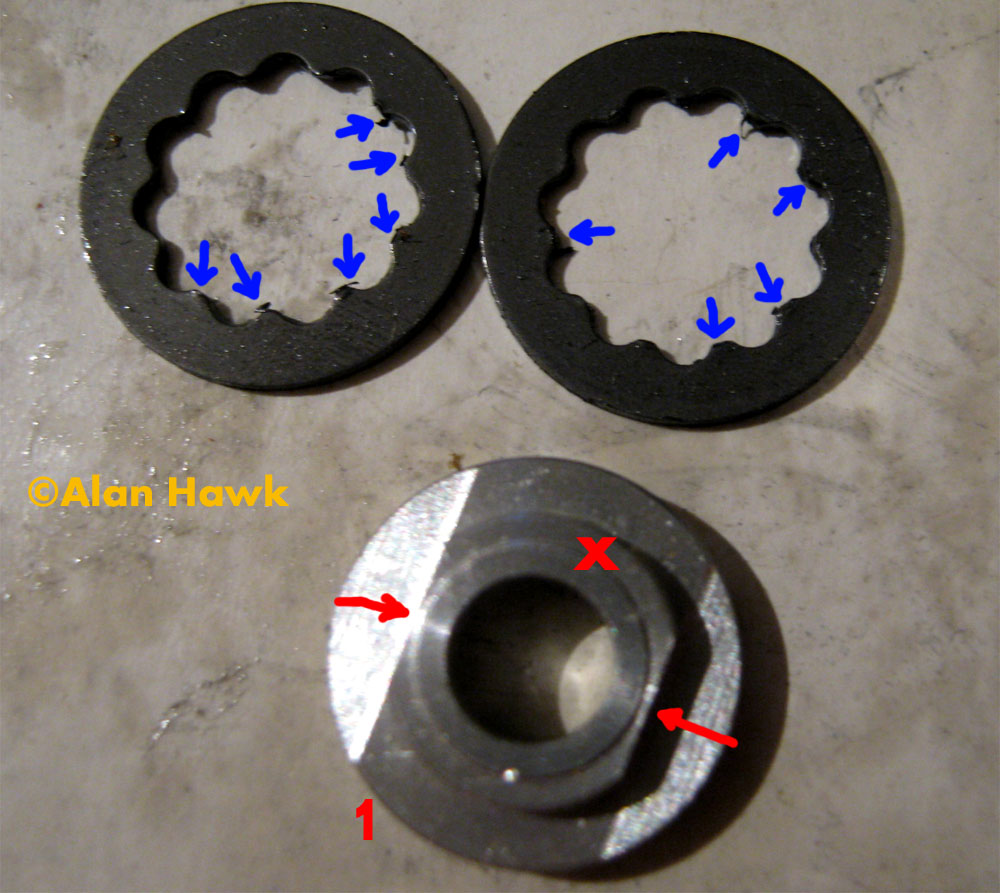

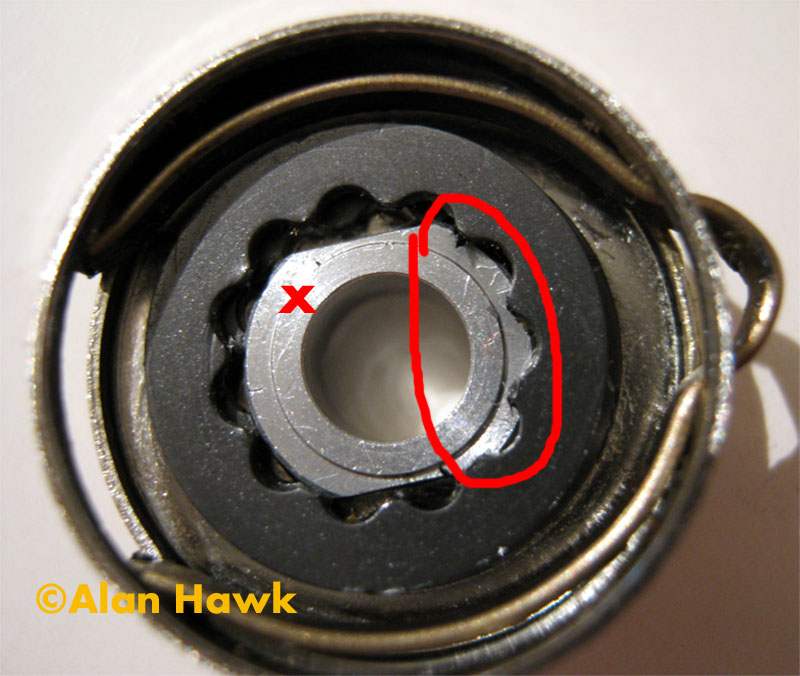

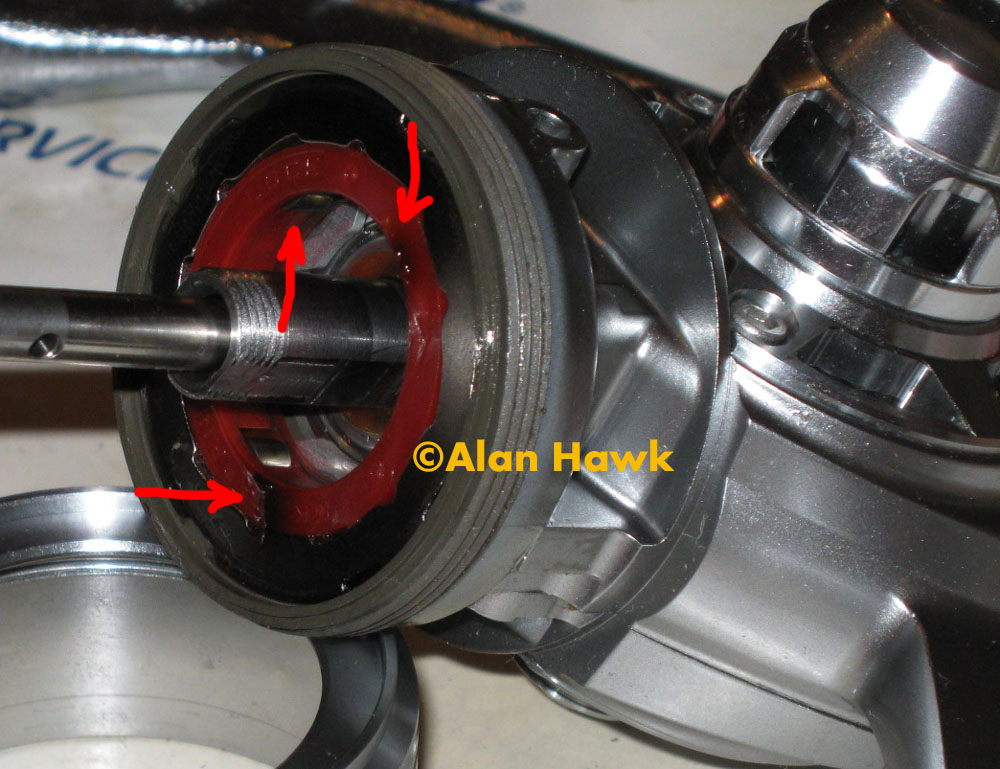

The spool rests on this small plate (1). The plate has a raised part (x) that has two cuts to its sides (red arrows). The raised part is supposed to accommodate the spool shims and prevent them from rotating. As you can see on the shims, they get partially damaged (blue arrows) once inserted because the star shaped hole in them does not match the raised area on the plate. But this is just a secondary problem.

The main issue is that the raised area (x) has enough height to accommodate only one shim. So when the second shim is put on top, nothing keeps it from moving around and becoming off centre. Keep reading

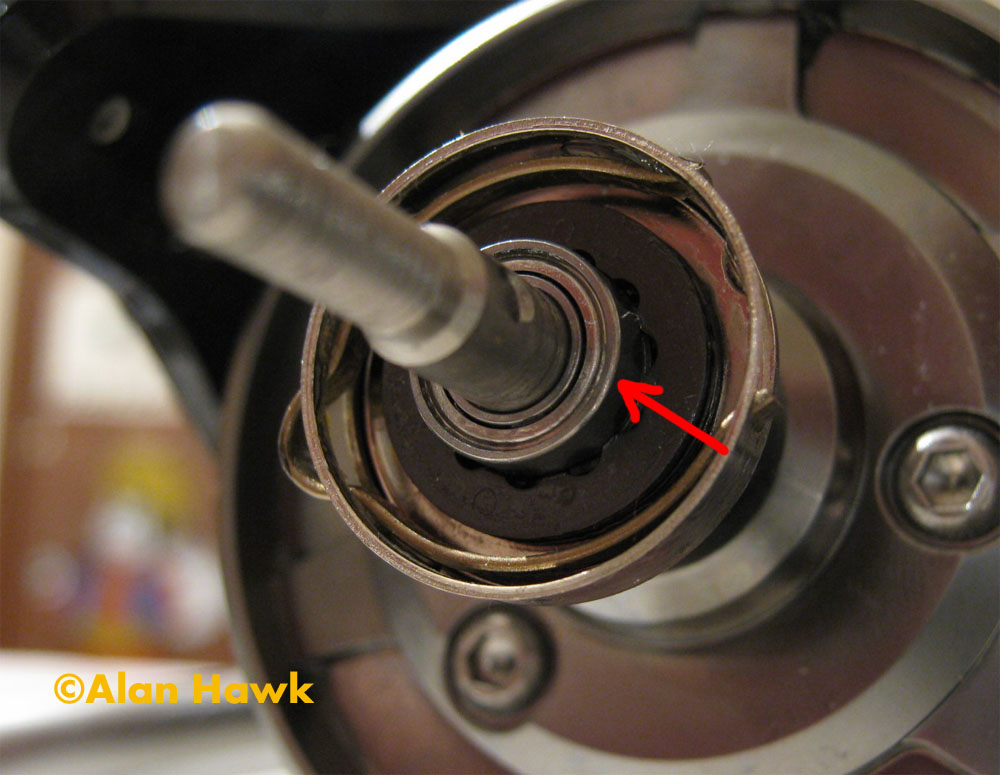

The ball bearing (arrow) sits right above the raised area we have just seen. But because the second shim does not fit on that raised area and is free to move off centre, that second shim gets wedged either underneath or around the bearing preventing it from rotating like a normal bearing should do. So basically the design can't accommodate a second shim, and if that second shim is inserted it stops the bearing from functioning so that when the spool gives line it actually slips around the outer race of the non-functional bearing.

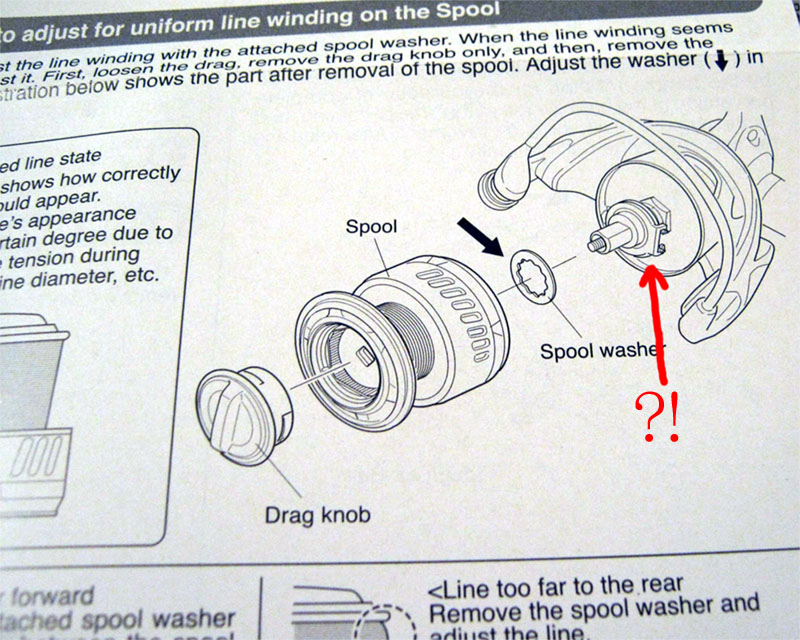

And to round this shims deal up, the reel's manual has the familiar drawings of wrongly filled spools and directions to add or remove shims accordingly. The drawing shows a shim being inserted/removed innocently as if nothing was out of order. Here is that shot from the manual;

Well, I dare anyone reading this to try and remove one of the shims or insert one! This is not going to happen. The only way shims could be inserted or removed is if the O ring was removed followed by the retainer pin then the entire hub taken off then the bearing, and only then a shim could be added or taken off. Trying to remove a shim straight as the "innocent" drawing shows will leave you in tears of failure, and forcing one down will damage the O rings. Funny enough, in the above drawing from the manual the reel drawn is definitely 2010 Saltiga (look at the spool), but they drew the spool hub intentionally wrong to resemble the inverted type of the Certate in which it is possible to add or remove shims without damaging anything!!! Hmmmm

The spool hub has a seal inside (arrow) as well to prevent water from slipping underneath the hub to the washers. I tested rigorously and found the spool to be 100% waterproof and water can't possibly get to the drag.

Speaking of sealing, the reel's body is also 100% waterproof. It got dunked, cranked underwater, and as a final test I left it for 24 hours at the bottom of a fish tank, yet not even moisture got in. In the above photo you can see the shaft's seal (red arrow) protruding from underneath the nut retaining plate (x). I will be showing you details of the sealing as we go forward.

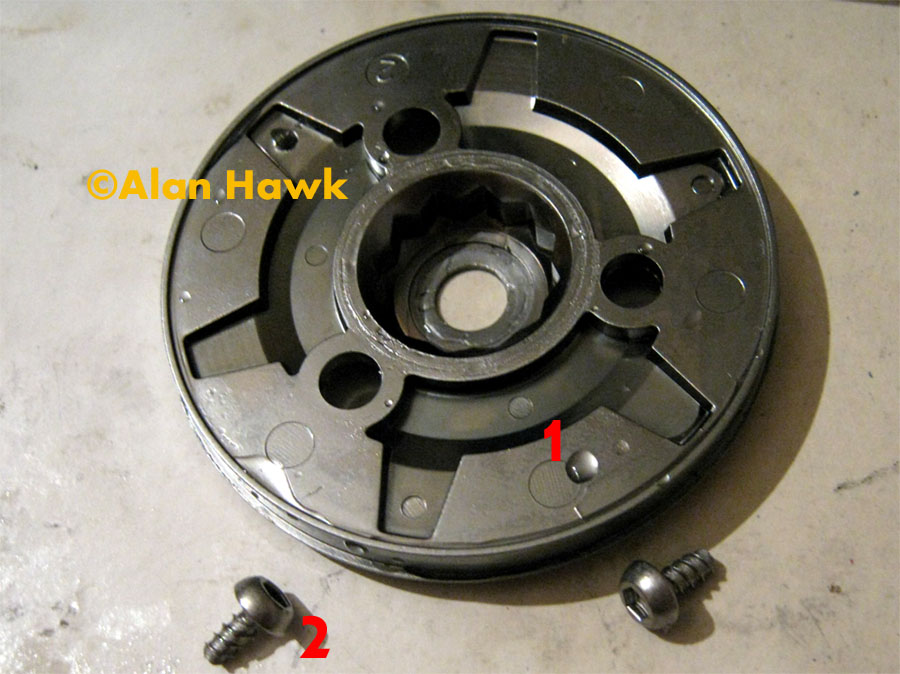

The other side of the nut's retaining plate (1). It's made of plastic, and you can see its screws (2). These screws have large pitch threads because they are screwed into the plastic rotor. You are of course aware that for materials such as plastic or wood, large pitch threads are required, while small pitch threads are used when threading into metal.

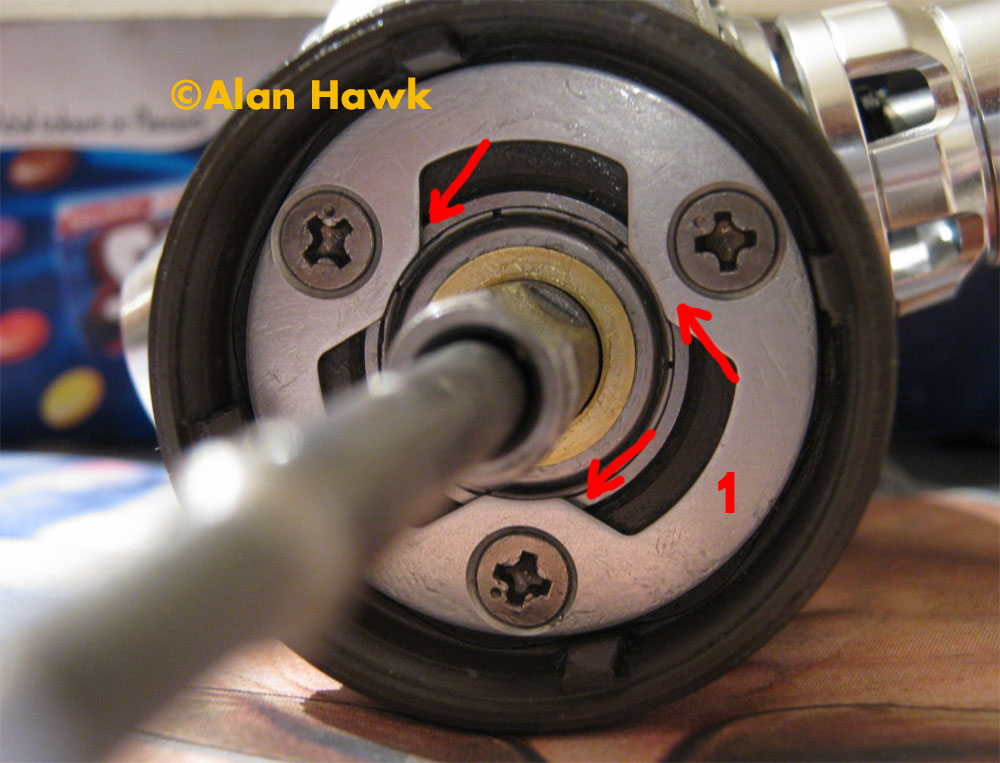

The rotor nut. Here you can see the shaft seal (1) in full, and an O ring seal (2) to prevent water from coming in from underneath the retaining plate shown on the previous photo.

The seal (1), a washer to reduce friction between the shaft and the nut's bearing (2), and the bearing itself (3). I have explained that bearing in detail before, but quickly, it's there to isolate the shaft from the rotor. It's an essential feature invented by Shimano for the Stella F series back in 1998, and since then has been copied by other makers for their top reels. When the reel is used under load, this feature (called "floating shaft") eliminates the braking effect and the power loss due to friction between the shaft and the rotor (specifically the inner wall of the pinion), and the difference is real and felt in smoothness and efficiency particularity when the reel is cranked under load.

The rotor

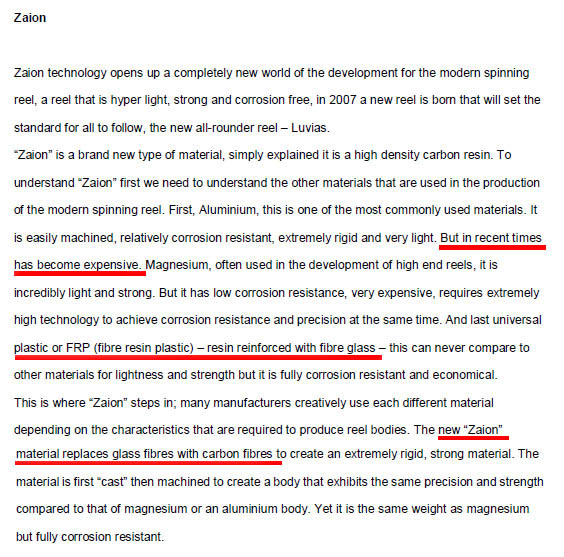

The rotor is made from what Daiwa calls "Zaion". We first need to understand what that material is and what it isn't. Right now Daiwa publicises it as a breakthrough material that belongs on its respected Saltiga merely because of its properties. Well, I have a pdf called "Daiwa Technology" that Daiwa released in 2007 when they had no idea they would need to use it on a future Saltiga. Here is what is written under "Zaion" in this pdf

I underlined three parts. The first is the key: Aluminium is expensive. The second underlined bit tells us basically that "universal plastic" is "resin reinforced with fibre glass". Keep this definition in mind as you read the third underlined bit; "Zaion material replaced glass fibre with carbon fibre". This means that Zaion is a form of plastic in which glass fibres are replaced with carbon ones. So it's plastic in Daiwa's own words, but now it's used on their $$ Saltiga, they no more refer to it as plastic and use fancy words such as "carbon composite". Not really different than the use of the word "graphite" by tackle manufacturers to describe the common type of plastic used to make low cost reels. Zaion was introduced in 2007 as an upgraded version of the common graphite to make their mid-range reels, and Shimano responded by introducing their Ci4 material with identical properties, but their high end Stellas remained exclusively made of expensive and rigid metals such as aluminium and magnesium.

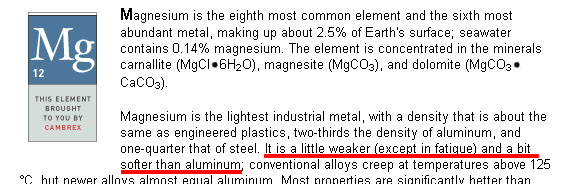

The new Saltiga has a larger diameter main gear which is made from the dense and heavy C6191 Marine Bronze, a more dense body alloy to avoid breakages and handle the considerably higher maximum drag, and the mag seal. These features added weight to the reel, and a plastic rotor was used out of necessity. Just think that even with the new rotor, the reel is still heavier than the old Saltiga, and that would make it clear that with aluminium rotor the weight would have been a big disadvantage. I needed to make that clear because Daiwa is justifying the use of a plastic rotor by some ridiculous statements; in the advertisement videos they say that it moves the centre of mass of the reel back for more comfort for the angler, which is as ridiculous as saying that a Boeing 747 will use less fuel if one of the passengers spits his gum before boarding! They claim that Zaion is nearly as strong as magnesium, and they leave the definition of "nearly" open to each person's interpretation. Still, even if it was as strong as magnesium (it isn't), magnesium is still softer than aluminium. Here is a screen shot from the site of the American Chemical Society. Google sentences and you will find it on the society's official site:

Now we have established what it is and why it was used, I will say that the rotor is not at all bad. If you hold the rotor of the new Saltiga between your fingers and squeezed the two cams together, you will feel a flex not different than that of any low cost plastic reel. No one can even compare that to metal. But, once the flexing reaches a certain point, the new supporting arches come into play and stop the bending before it reaches the breaking point. The strength of the rotor does not come from the material, rather from the unusual design. This plastic rotor will withstand more load than the aluminium one of the old Saltiga, but only because the old rotor was thin and had no reinforcement in areas where it mattered. The arches are marked by red Xs in the following photo

I wished I could catch something that would test the full 33lbs of pressure the reel is supposed to handle, but nothing like that came my way. So instead I tested it on dry land, and I can report that the reel handled the 33lbs perfectly. I did expect the rotor to snap or the shaft to bend as I lifted the 15kg dumbbell with the reel in its most vulnerable position (the spool fully extended and bail opposite to stem), but it did not break and the dumbbell hung clear off the floor as the bail arm stopped flexing few millimetres from the spool This test was done after I disassembled the reel and took photos of the internals for this review by the way.

In the above photo, red arrows point to dark brown stains on the rotor. Guess what that is?

This is the fishing world's first glimpse at the much talked about magnetic seal. The water drops you can see is freshwater that I had just rinsed the reel in after my final day's fishing. As you can see the water was stopped efficiently by the seal.

Another view of the mag seal

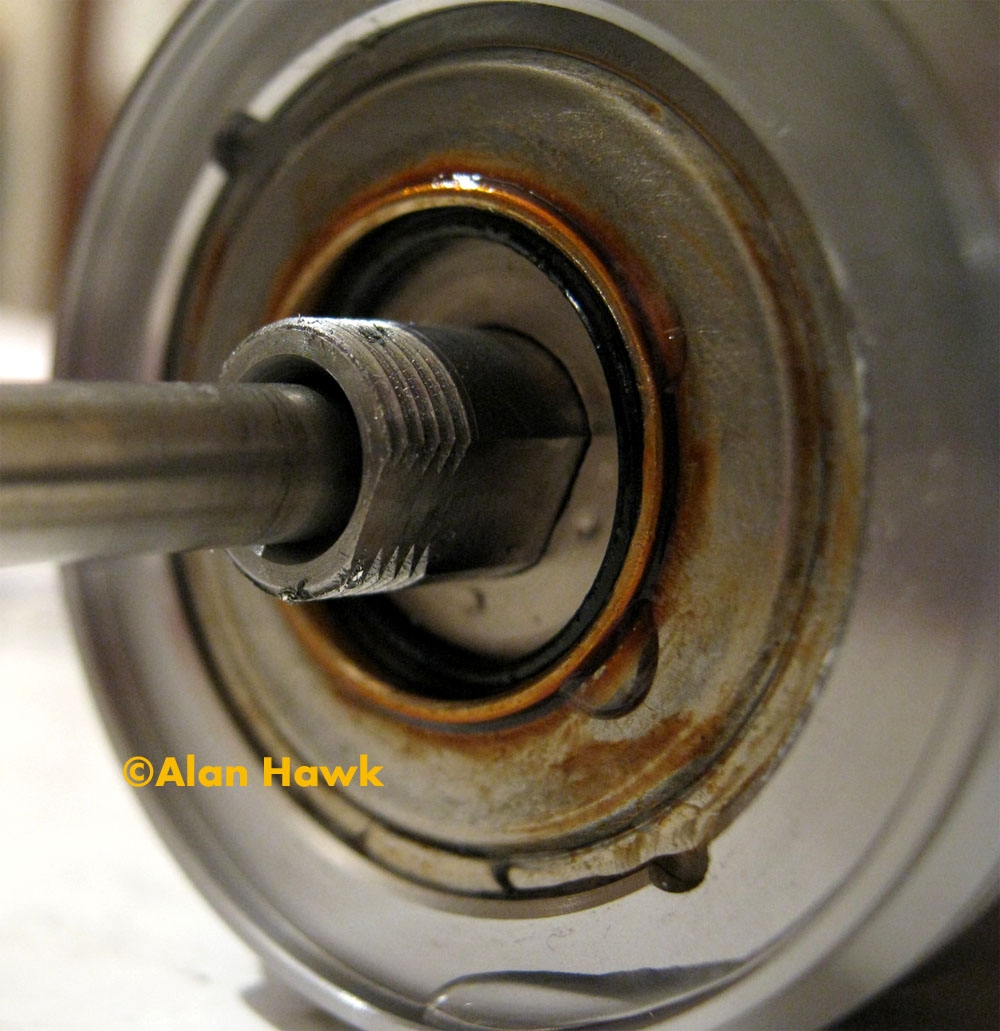

Here you can see the revolving sleeve (1), the housing (2), and the ferrofluid between them (red arrow). You can also see an O ring seal (3) to seal the meeting point between the rotor and the revolving disc, and finally, you can see the magnetic fluid's brown smudges everywhere!!!

At the beginning I thought that these smudges were due to a messy operation of injecting the fluid during assembly, and it was fine by me as it won't harm anyone even though it looks crude. Then I removed the mag seal....

Can you spot it yet?

With flash for more visibility

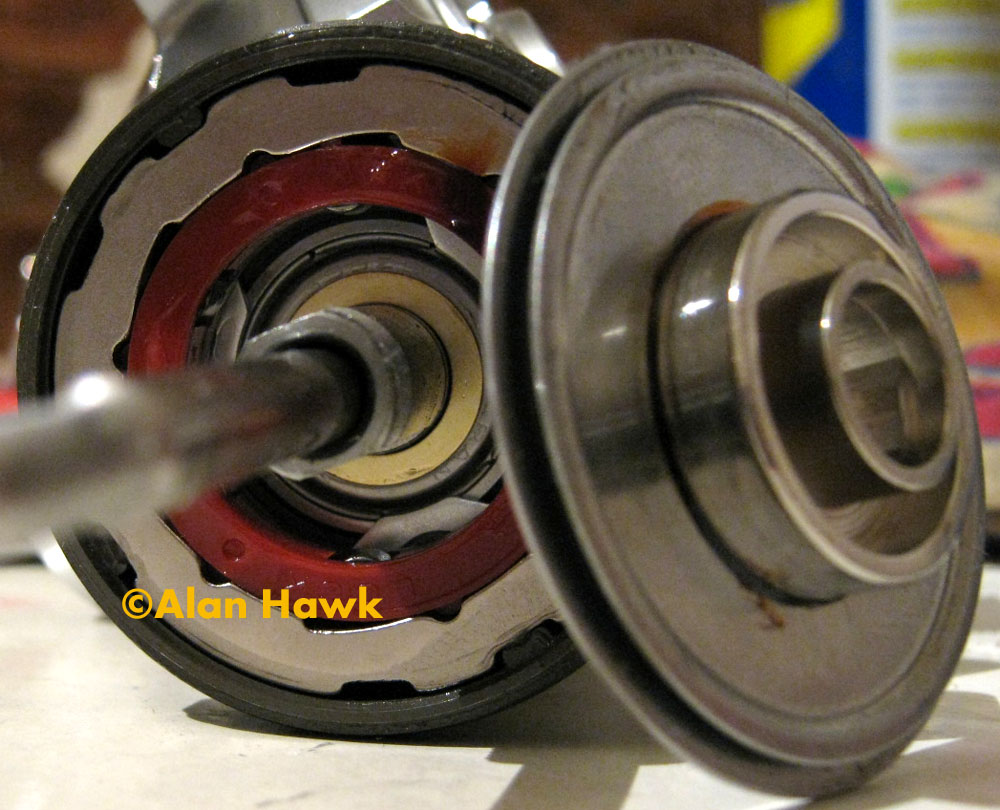

Yep, the mag seal squirted the ferrofluid all over the one way clutch!!! (red arrows). Here is the story: on the 7th outing with the reel, we were catching good size Ling all morning, and at the end of the day as I rinsed the reel I could hear a funny sound. Not squeaking or clicking, rather a subtle "wuch wuch" as I turned the handle. Anyone else could have missed that sound, but I have good senses when it comes to spinning reels, and I knew something was wrong. Nothing of what had been caught on the reel at that point (or afterwards for that matter) was bigger than 30lb, so it's not as if the reel was abused by massive fish. I had originally planned to fish the reel more then review it at the beginning of December, but because I felt that something went wrong I decided that I will disassemble the reel earlier than planned, and here you have it. Now the reel was opened, I knew it was the squirted ferrofluid invading the anti-reverse clutch and making that subtle sound. Well, that did not stop the reel nor will it stop any Saltiga from functioning in the short run. Only prolonged use would show what a fluid with suspended iron microparticles will do to the one way clutch.

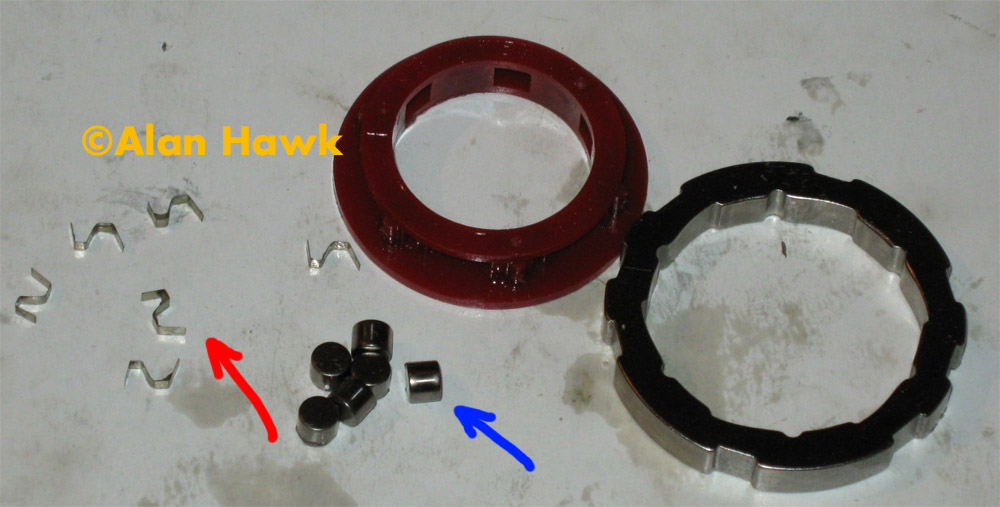

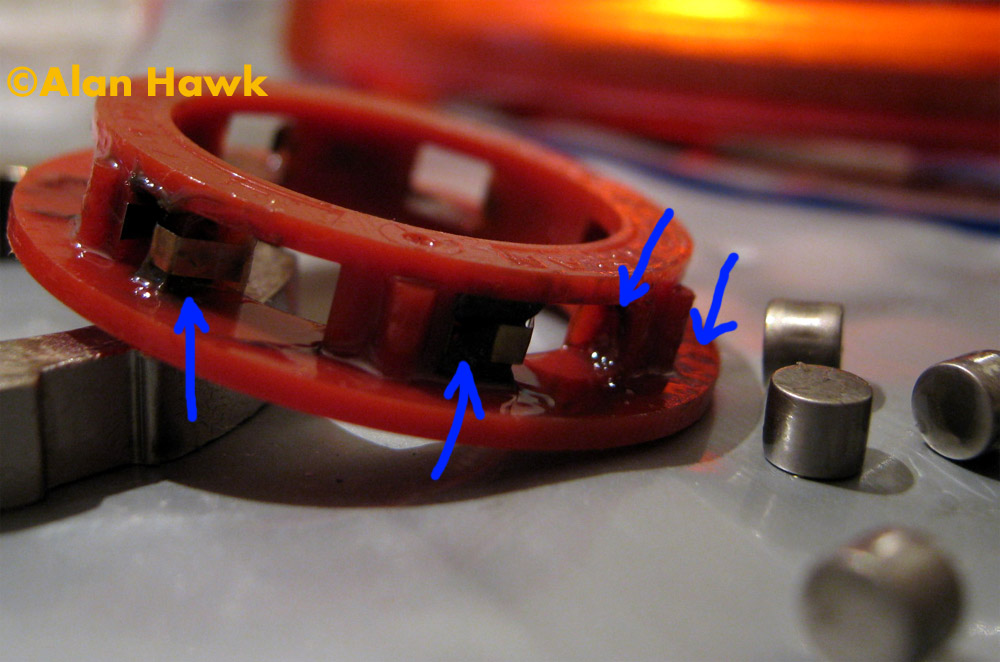

The clutch is the tried and tested design by NSK that Daiwa has used since the 1994 Team Daiwa TDX. Here it is disassembled and ready for cleaning. The red arrow points to the springs that keep the brake cylinders (blue arrow) under constant pressure for a sure locking action without any back play .

Look how deep the ferrofluid has penetrated into the clutch, carried on the cylinders and deposited behind them. More is scattered around the red cage

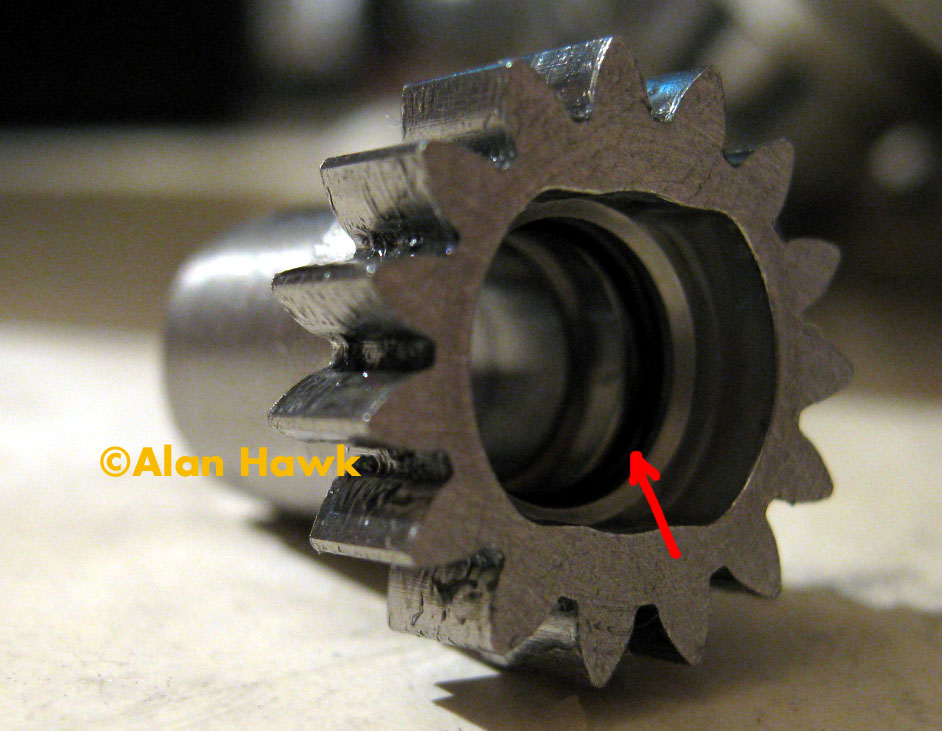

As I proceeded to disassemble the reel I noticed something about the main bearing (pinion's bearing). As I turned the handle and looked closely, I could see that as the inner race revolved, the whole bearing slipped and revolved too at a rate of about one full turn of the entire bearing for every about 40 turns of the inner race. My video camera can't capture that or I would have posted a video showing the entire bearing revolving slowly in its recess. This is the result of what I consider a major design fault; Instead of using a normal full contact retaining ring to keep this most vital bearing secured, they used a weight saving (!!!) design in which the retaining ring (1) only touched the bearing via three flaps! (flaps pointed by red arrows). With fish hitting the rotor hard and the stress transferred to the retainer ring that attaches the rotor to the body, these tiny flaps got bent outwards slightly, relieving the pressure on the main bearing and allowing it to play about a millimetre in and out and rotate like that.

This is the magnetic seal disassembled to fulfil your curiosity... and mine

The magnets and magnetic oil are housed in the circular reservoir pointed by the red arrows. The disc (x) double tasks as anti-reverse sleeve (the part marked by blue line) and also as a magnetic seal lip (the part marked by green line). The magnets and magnetic oil are housed in the circular reservoir pointed by the red arrows. The disc (x) double tasks as anti-reverse sleeve (the part marked by blue line) and also as a magnetic seal lip (the part marked by green line). In order to get inside the gearbox, the rear shield had to be removed.

This was a pleasant surprise! The rear shield (1) is actually made of stainless steel. If you read my review of the Stella SW, the only criticism I had for it was that shield because it was plastic. A good argument here would be that this shield should be disposable because it's there to receive hits and scratches. Stella's plastic shield is 1000 Yens ($12), while the stainless steel one on the new Saltiga is 5800 Yen ($70) according to both makers' official parts sites. So while Stella's is more appropriate for a disposable bumper, I still like the stainless steel one of the Saltiga more, being the only metal body shield on any spinning reel in the world. The black piece in the above photo (2) is actually a rubber seal. In the Stella it is just a solid spacer with zero sealing qualities because the plastic shield can't provide enough pressure on a seal. This way water stays completely out in the Saltiga, while in the Stella water gets in (but not into the gearbox which is sealed behind the shield) then drains out via two holes at the bottom of the shield which could be seen in Stella's own review.

The gearbox. The yellow arrow points the gearbox seal, and the blue arrow points the friction ring of the rotor's brake. The reel has a manual bail return by the way, still the rotor has an excellent brake to hold it still when the bail is opened for a cast. There is an emergency mechanical stop (red X) that engages the teeth mounted on the back of the drive gear (red arrow) if the one way clutch slips in cold weather or with wear. This design is another of Daiwa's cost saving measures. The big Saltigas have a different emergency mechanical stop that engages steel teeth behind the pinion, so that when engaged there will be no pressure on the teeth at the meshing point between the pinion and drive gear. That is the right way to do it, but they save it for the big ones only. The Stella SW on the other hand has a proper mechanical stop that engages steel teeth behind the pinion in the big 18K & 20K as well as the 8000/10000 which are the equivalent sizes of the Saltiga 4500/5000.

The drive gear bearing. The same stainless steel bearings from the old Saltiga. You can see the origin of the bearing marked on the shield "Thailand". If you look at the Stella's review, I photographed "Japan" on the bearing shield. All bearings in the Stella are Japanese made corrosion resistant type (Shimano calls it ARB anti-rust bearings), while in the new Saltiga only the 2 bearings in the line roller and the 2 ones in the handle knob are corrosion resistant (Daiwa calls it CRB corrosion resistant bearings), and only one bearing is marked "Japan".

Here it is. They chose a larger bearing for the pinion because of the amount of load it has to handle. This is the bearing that slips in its recess, discussed earlier.

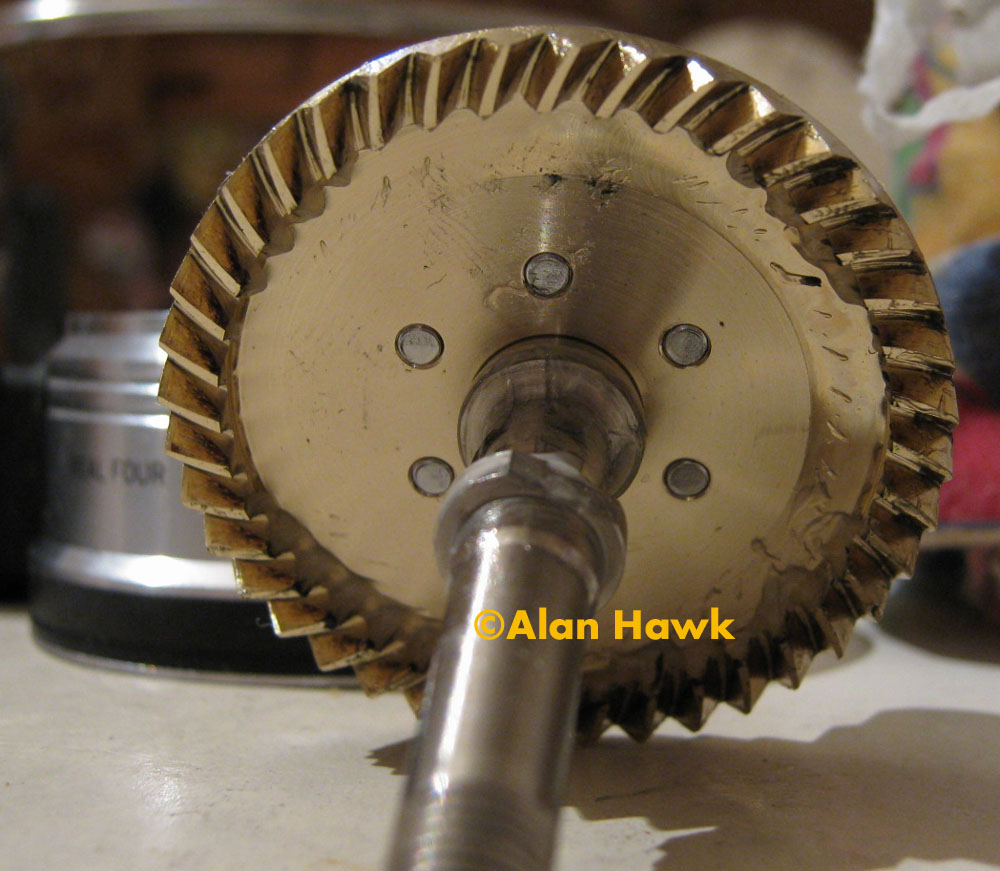

The Drive gear. The exact same digital cut gear machined from C6191 aluminium/bronze alloy as in the old Saltiga. That process of gear making achieves the biggest contact area between the teeth of the drive gear and those of the pinion for the longest time possible during their engagement/disengagement cycle. This reduces the stress in the teeth and gives the gear its legendary longevity. The gear in the new Saltiga is of a larger diameter than the old one to transfer more torque to the pinion. I think Daiwa and Shimano have achieved the highest level of strength and durability for their gears and I don't doubt that in the next generation of Stellas they are going to use the same gears that are in the SW now. Shimano cold forges the gear then surface treats it which creates a light and extremely strong gear, and Daiwa machines a heavier alloy in a precise numerically controlled process that creates a heavier gear but one that is quieter than Stella's. Both drivetrains though are indestructible.

Closeup on the gear's teeth. The dark spots are burned grease, something that gives me satisfaction that I did put sufficient use on it in the time I spent testing it. Before I move away from the gear, I need to comment on something because I hear a lot of misinformation about Daiwa's gears. (January 2017 edit: the following description of gears' names is now outdated. Check this review for the latest naming of Daiwa's gears). People think that "Hyper Digigear" and "Digigear II" are different than the original "Digigear". That is not right. At the beginning all drive gears made using that process were called "Digigear" by Daiwa regardless of what material was used. Then Daiwa renamed their first tier gears to "Hyper Digigear", which is a drive gear made of C6191 aluminium/bronze alloy (usually coupled with a stainless steel pinion), and they renamed their second tier drive gear "Digigear II", which is a drive gear made of duralumin (usually paired with a brass pinion). So it's just new designations, but gears are still made the same way as the originals. I've seen some people mistakenly describe the gears in the new Saltiga as "Digigear II" instead of the correct "Hyper Digigear", but hopefully now there will no longer be such confusion.

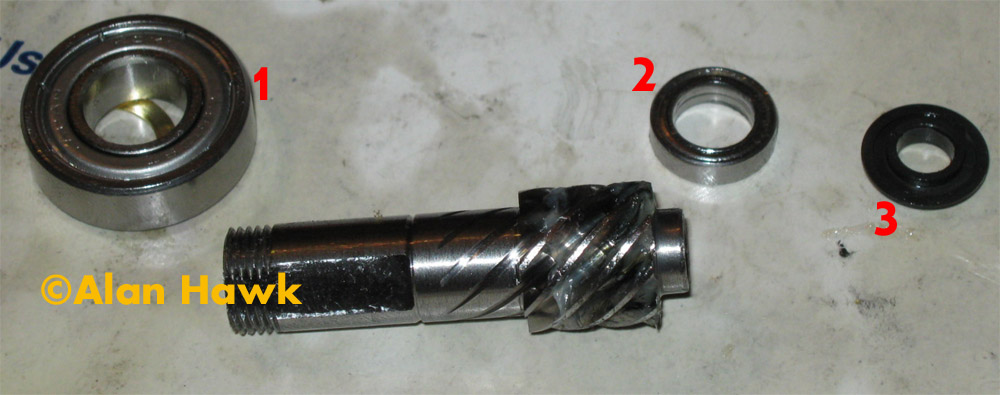

The stainless steel pinion. It runs on two bearings; the big one described before (1), and a tiny one (2) on the inside end. You can also see a synthetic washer (3) that goes in front of that tiny bearing to isolate the main shaft from the pinion. This is the second half of the "floating shaft" feature. The first half is the bearing shown near the beginning of the review inside the rotor nut.

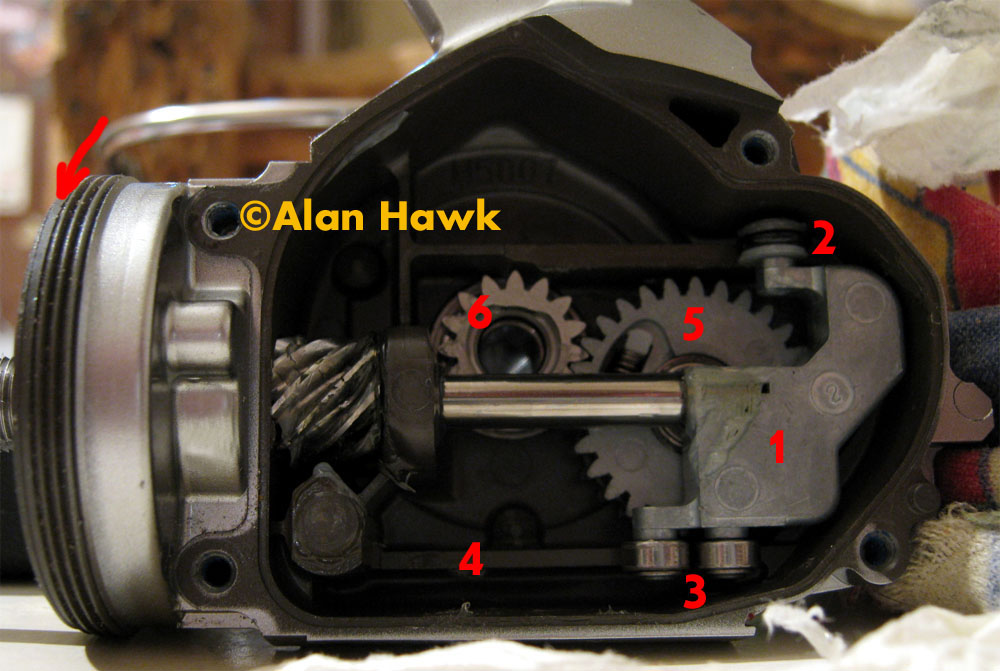

The gearbox with the drive gear out. The traverse cam (1) has changed significantly. When I reviewed the old Saltiga in 2002 I mentioned that the ball bearing on the top of the traverse cam was redundant because the one at the bottom is the one that comes into action when the reel is operated under load. Someone finally got the point and the top bearing was removed and replaced by a synthetic washer (2) with a rubber ring around it. That rubber ring makes the running quiet, and it pushes the traverse cam slightly up so that the bearings on the bottom (3) stay in contact with the rail (4) constantly to eliminate any clicking sounds. There are now two bearings on the bottom instead of one. These bearings guarantee a smooth rolling action when the main shaft is twisted hard clockwise (if you're looking from the spool's end) under load, but again, the second one is redundant. A single bearing only can do the job perfectly and it won't fail even at the new higher drag rating. The line lay gears (5) are quite similar to the old ones with a subtle change to the way the bearing is mounted, and the gear that activates the line lay gear (6) is straight from the old Saltiga. The red arrow points to the O ring that seals the outer rim of the clutch/magseal assembly.

A closer look at that activator gear shows an O ring seal inside to prevent water from slipping between the gear and the main gear's shaft.

The main shaft (1), and two gears composing the line lay gear; The grey gear (2) is cast aluminium alloy, and the white one (3) is synthetic.

Closer examination of the traverse cam shows imperfections from the casting process. Not that these tiny holes would harm in any way, but just sharing an observation.

Close up on the stud of the line lay gear. In the old Saltiga this stud had a synthetic full-length sleeve to reduce friction between it and the walls of the traverse cam, but the sleeve is gone and an O ring (arrow) has been fitted near the top. This O ring keeps the action quiet, and when there is no load, only this ring would touch the walls of the channel to spare the stud itself excessive wear because an aluminium stud rubbing against aluminium walls is a recipe for rapid wear. The longevity of the O ring and this whole arrangement remains to be seen with time, but I am quite convinced that the old Saltiga has a more durable design in this area even though it was not as quiet. This and the rubber ring on the top washer of the traverse cam are the components of what Daiwa calls "Silent Oscillation".

The line lay gears assembled. You can see the teeth of the white synthetic gear from between the teeth of the grey aluminium alloy gear. The coil spring (1) pushes the two gears in opposite directions, and that makes their combined teeth grip the teeth of the activator gear seen 5 photos above. Again this eliminates gear play and makes it run quieter.

I have said in the past that this traditional locomotive line lay system is not suitable for friction free operation. The ball bearing in the centre (2) causes more problems than it solves. Ball bearings by nature have internal radial and axial play built into them, therefore it's impossible to use a single bearing to create a stable system standalone. The main purpose of the white synthetic gear beneath the line lay gear is to act as a washer to reduce friction between the gear and the body. And friction DOES exist because of the internal play of the bearing, making it inevitable for the gear to rub against the reel's body. Look at this...

Here you can see the finish damage on the circular rail underneath the gear in this 17 days old reel. The finish of the body is being ground off slowly each time you turn the handle as the body supports the shaky line lay gear. The following photo is of the old Saltiga 6000 where the same damage to the body can be seen.

That damage will not reach a point where the gear would dangerously tilt or anything like that. But that is a design deficiency that creates constant friction making the whole idea of a 14 ball bearings reel seem quite pointless. It creates tightness in the movement, and while wear and tear is acceptable in gears and parts, it's definitely not acceptable for a part to dig into the body of the reel itself. This highlights the superiority of the worm gear line lay of the Stella. The worm gear is suspended on two bearings, one at each end, free to spin perfectly stable with no friction or rubbing.

The reel being reassembled and greased with Ardent synthetic grease, while Daiwa's molybdenum grease was used on the main and pinion gears. Moly grease should not be used near ball bearings because it could ruin their function.

This is the new approach to sealing, mainly inspired by the Stella. In the old Saltiga there were two internal thick seals permanently sealing the drive gear shaft on both ends. That meant that whenever the handle was turned you had to work against the friction of two seals on the drive gear alone. On the new Saltiga these two internal seals were replaced by two external ones that are not in contact with the gear shaft.

A closer look

When you screw in the handle to one side, this external seal on that side fits around the handle's shaft, perfectly sealing that side. The opposite side would normally be covered by the screw-in cap, which fits around the seal on that side, again perfectly sealing it. This way when you turn the handle you work against the friction from only 1 seal instead of 2 as in the old model.

You probably get the concept now. With the new approach to sealing the gear, if they had sealed the pinion using a traditional rubber seal, the reel would have been less free spinning than the Stella because of the tightness and friction of the line lay system discussed earlier. It needed an edge, and the -virtually- friction free magnetic seal gave the new Saltiga that edge, taking over the Stella in terms of free spinning.

Here you can see what Daiwa calls "Engine Plate" (1), the sheet that has the ornate detail (2), and an O ring seal to keep water out (red arrow).

The back of the bail arm. Now there is a security screw (1) to keep the roller's main screw (2) from becoming loose. Again, inspired by the Stella SW.

The bail arm is stronger than the old model. Don't let the black finish confuse you, it's actually metal. You can see the bail arm screw which, too, has large pitch threads because it's screwed into the plastic rotor.

They use a lot of loctite to secure the line roller screw. Needed to clean all that mess before I reassembled. The red arrow points to the seal fitting snugly inside a little recess and effectively keeping water out.

The other side of the roller, and a similar seal here too.

Everything out. Line roller (1), seals (2), and corrosion resistant ball bearings (3).

The handle knob. Round metal knob comes standard with the new Saltiga. (1) is the top half of the round knob, (2) is the bottom half, and (3) is the screw the holds both halves together.

The screw has an O ring seal to seal the outer side of the knob.

The handle knob's shaft; The other pair of corrosion resistant ball bearings (1), and a rubber seal to seal the inner side of the knob (2). That makes the knob perfectly sealed on both ends.

The bail mechanism. The simple and reliable concept from the old Saltiga, with a change in the way the mechanism engages/disengages the rotor casting brake (arrow).

A better look at the rotor brake. When the bail is closed, the spring loaded lever (1) rests underneath the bail spring's guide (2). When the bail is opened, the guide presses the lever further down until the other end of it engages the friction ring shown in the following photo

That friction ring (rotor's brake) is exposed and can be accessed easily through the cutaways in the rotor. This exposed location of the friction ring is a two edged sword. For one it makes it easy to put a protective layer of oil on the ring then wipe it off, but it also makes it exposed to the sun, and we know what the sun does to rubber rings. Periodical oiling of this ring is a must.

Finally, the new spool lip. As you can see it's a conservative copy of Shimano's reverse tapered lip. Have not tested it side by side against the old Saltiga for long distance casting because I don't have a 4500 size old Saltiga, but judging from the effect of Shimano's lip design, I think it's safe to assume that the new Saltiga will have some advantage over the old one in distance casting.

Now let me explain to you what you have just read. I have just reviewed one of the most expensive reels in the world and one that is supposed to be up there with the Stella. At that elite level it's important to have a very critical eye for imperfections and design flaws. If you are examining a Bentley, finding a rough spot in the wood trimmings would be a major problem, but if examining a Toyota a "major problem" is going to be nothing less than an engine malfunction. Do you understand what I mean? Had I been reviewing a $250 reel, I would not have bothered checking if the line lay gear rubs against the reel's body. But because I am comparing this $1000 Saltiga to the extremely refined Stella SW in which everything floats on bearings virtually friction free, that gear rubbing issue in the Saltiga becomes deserving of a mention.

From an aesthetic point of view, the 2010 Saltiga marks a new era where the Stella becomes alone in that exclusive top league. The Saltiga is not comparable or even in the same league anymore. Can't say that I am not hugely disappointed. On one hand I paid about $1400 for the reel including shipping and HM customs and import duty and Parcelforce fees, and that is not small change. But I'm even more disappointed because I consider Stella SW to be -along with Abu's Suveran- the finest spinning reel ever made, and because I love fishing gear regardless of the brand, I wanted Daiwa to introduce something that takes the game even higher and kicks Stella's butt. I had in mind how for 7 years I considered the old Saltiga to be the king of reels over the Stella FA, and I expected the 2010 Saltiga to repeat that with Stella SW. But all that anticipation was for nothing, and now I have nothing major to look forward to for at least 6-7 more years until maybe Shimano would decide to upgrade the SW.

I think Daiwa's philosophy with the Saltiga is different than Shimano's with the Stella. Shimano seems to embrace the exclusivity of the Stella name more than Daiwa does with the Saltiga. "Stella" is the flagship spinning reels and nothing else, while Daiwa milks the name "Saltiga" for every last pence they can get out of it; Saltiga Blast, Saltiga Game, Saltiga Surf, Saltiga conventional, Saltiga rods, Saltiga braid, Saltiga lures, etc. Shimano seems to spare nothing for their flagship reel, while Daiwa partially ruined the new Saltiga for the sake of making money from the owners of old Saltiga and lesser quality Daiwas! How is that? Well, Daiwa left the cumbersome spool hub unchanged along with the bearings arrangement, drag dimensions, old un-kyed drag knob etc, all for the sole purpose of making spools interchangeable with other reels and so that owners of 2001 Saltiga and even some Chinese made Daiwas such as the Saltist could buy the new spool to make use of the new drag material and the spool lip etc. Shimano redesigned the spool of the SW to protect both bearings permanently inside and changed the mounting to eliminate tilting etc, then made a lesser model (Twin Power SW) to the same dimensions so it could take some of Stella's spools. This is a good way to do it; update the flagship reel to the best design possible, then make lesser reels to the same dimensions. But to leave an old design on your top reel unchanged in order to sell spools to older and lesser reels' owners? I don't know about that. Also, keeping that old spool design means that Saltiga can't have a drag system underneath the spool. The twin drag underneath the spool on the Stella 18K and 20K will remain unchallenged for its large surface area generating high pressure with low stress and rapidly dispensing heat to the air through the metal bottom plate that works as a radiator. Even smaller Stella SW 5000, 8000, and 10000 each has a drag washer underneath the spool as a secondary system in addition to the main top stack.

But aesthetics and design refinements aside, the new Saltiga is still a great machine. Practically it is structurally strong with a body able to handle the stresses of its maximum 33lbs of drag, it's freer spinning and smoother than the Stella, and it is not going to breakdown as long as it's used within its design limits. It is also 100% waterproof because of the effective sealing throughout, and even with the magnetic oil flying everywhere, enough of it stays where it belongs sealing the pinion assembly effectively. Metal plating chipping from the knob clicker or a line lay gear sanding off the body or a jammed ball bearing in the spool are not going to stop it from bringing in fish over and over. Adding or removing a spool shim is something that is not done very frequently, and with some tools and careful disassembly of the hub it could be done, and wiping the exposed friction ring with an oily cloth every few trips is not such a big deal.

As I said before, a modern reel is basically three things: strong gears, drag, and an anti-reverse. The gears of the new Saltiga are the tried and tested work horses, the drag is as brilliant as a top stack drag could get, and the anti reverse clutch is well designed and reliable, and even if the magnetic fluid squirted into it proved to accelerate wear, the mechanical emergency stop will kick in and keep you fishing until you fix or replace the clutch. The reel is not up there with the Stella, but it is still an excellent reliable reel that I enjoyed fishing, and if I make a short list of the best 5 reels in the world it is definitely going to be somewhere on it.

I hope you enjoyed the read. At some point in the near future I should be getting myself a Van Staal VM 150 to fish and review, but next it's Penn Torque's turn to be reviewed with a full fishing report.

Cheers

Was this a good read? Please click here

Alan Hawk

November, 21st, 2010

|