Daiwa BG SW : The Review

Hello fishos

I'll begin with a couple of important comments, and you can skip the first two paragraphs if you want to get right to the BG.

I've been receiving a lot of premature questions about how good some unreleased reels are, with the Makaira and new Fin-Nor Offshore being the most mentioned ones. I said "premature" because I can only form an opinion and draw comparisons after fishing and fully testing a retail bought reel. I know there are videos and specifications out there, but that doesn't make me able to form an informed opinion. Data sheets and metallurgy can never replace real life fishing. Think about this; I could not have known by looking at date and parts that Saltiga Z's drag was sticky, or that the early 2010 Saltiga had issues with magnetic fluid retention, and if I had looked at the early Penn Torque for days I still wouldn't have found the serious issues which initiated a redesign and major parts swap, just to name a few examples. Please be patient and understand that until I test the retail reels I can only provide purely descriptive information, and there is no way I can say if an unreleased reel is a better or worse choice. One such descriptive answer to a frequent question I receive about the Makaira's drag, is that it resembles that of the Metaroyal Safari and TwinSpin only in the knobs arrangement, but its function is almost identical to the drag of Shimano's Baitrunner Spool II found on some long cast models (not the Baitrunner reels). I've seen some articles written about the Makaira by people who apparently don't use a wide array of reels (some are editors of fishing magazines and sites), so they never figured this one out and were instead describing it as something unique when it certainly isn't.

Moving on, if you email me and do not hear back in a few days, make sure to check your "spam" or "bulk" folders for my reply. Some email providers send genuine mail to spam/bulk folders, and there were cases where readers told me they found my replies there by mere chance. Also when you contact please make sure that you type your email address correctly. I still get messages with mistyped addresses, and ones where the sender enters his first name in the name box and last name in the email box. It bothers me to receive a thoughtful message or one with important questions only to discover that I have no way of replying. If you have emailed me and heard nothing back please try again after double checking your email address.

Of all the reels produced today, no spinning reel is as popular worldwide as the 1981 Daiwa Black Gold. Other classic reels like the Penn Z have a large following, but it's mostly localised in the USA and nowhere near the global phenomena that is the original Black Gold. The Daiwa's popularity comes from the simple design, ease of maintenance, parts availability, affordable price, and of course the almost legendary longevity proven over the past 35 years. Being of an older design that's not very braid friendly, Daiwa apparently saw no threat from that reel to its rapidly cycled modern reels line up, therefore they kept it in production that long and at the time of writing these lines the original Black Gold is continuing to be produced as normal.

Other than the black/gold colour scheme and the affordable price, there is no immediately visible linkage between the original Black Gold and the new one. Is it just a case of recycling an established name to give the new reel a false sense of heritage? We shall see about that, but first let's deal with the naming issue; the reel was initially referred to as "Black Gold" verbally and in casual exchanges, but officially it has been called only "BG". Probably the only time I've seen the full "Black Gold" name in printing in reference to this new reel was this clever play on words on the cover of this trade magazine

Since both the 1981 and 2016 models will continue to live side by side, I picked on the saltwater reference in Daiwa's banner shown two photos above, and decided to call it the "BG SW" to avoid any confusion with the original and so that I don't have to type the model's year every time I mention it. Now the name is settled, a quick photoshoot

There is no two ways about it. The reel is more than aesthetically pleasing. Extraordinarily beautiful sounds like a fitting description. The two main colours are complemented by the grey handle, the frame and rotor have the distinct futuristic styling of the high end Daiwas, the spool is quite wide where the line sits but then the skirt tapers backwards with a lovely reverse curving, and the gearbox gradually narrows rearwards to meet a very aggressive looking rear body shield. As far as looks go, this in my book is the second most beautiful reel in current production, next only to the Expedition. The Dogfight and the pale Saltiga reels do not even come close.

What comes with it

Not much. Two folded manuals, one general and one specific to this family of reels, and a small bag of shims to tune and adjust the line lay on the spool.

The manual is kinda weird. It tells you not to stick your finger in the reel because you might not be able to get it out. Well, my fingers have gone into some real funny places before, but I've never fingered a reel in my life whether intentionally or by accident. I'm therefore quite stupefied by this warning!

The reel's box is designed to hold it perfectly still, and there is even a space where one could put a popper or a few jigs. Might sound like nothing to you, but as someone who travels a lot this protective box was very useful to me when flying with it in the checked-in luggage since the reel is too cheap for me to risk the hassles of having it in my carry on luggage.

Speaking of the price, the BG SW retail from $100 for the smaller to $130 for the bigger sizes. This was one of those very rare occasions where I paid full retail for a reel, because I wanted it as early as possible due to the number of reels that I'll test over the next few months. I pulled every line I could and secured a late July delivery of my 8000 from one of the very first shipments, but the downside to that was having to pay the full retail. It's not really about the money as it is a matter of principle; you can almost always pay less than retail if you talk to a few online shops and Ebay sellers etc., or you could be patient and scan Amazon for a few weeks until you see a seller offering low prices. The going street prices for the BG SW since I bought mine has been ranging from ~$88 for the smallest to ~$115 for the largest.

The advertised weight of the 8000 is 850 grams (30 oz), and it actually weighs a hair less, which is a very good weight considering the extreme line capacity. With a capacity identical to those of the Expedition and Dogfight 8000, the BG SW 8000 is another full size reel with a line capacity that exceeds other full size reels, but remains short of the Mammoth size class reels. I examined production 4500, 5000, and 6500 reels as well, and found the weights to be generally accurate.

The spool has a rubber band (red arrow) in yet another attempt to make a spool that can take braid without mono backing. I insist that these never work 100% and that you must put a few yards of mono first to avoid a catastrophe while hooked to a once in a lifetime fish. If that rubber band deteriorates just throw it away and fish normally. You don't need to replace it. The blue arrow points to some interesting text...

The spool runs on one ball bearing (red arrow), and yes, the carbon fibre drag washers (blue arrow) are indeed lubed with Daiwa's mystical ATD lube. Note that in the BG SW they only use the initials ATD but never the full name "Automatic Tournament Drag", to avoid the issues with that naming which made them create ATD and non-ATD marked versions of the Saltiga as I explained in this article.

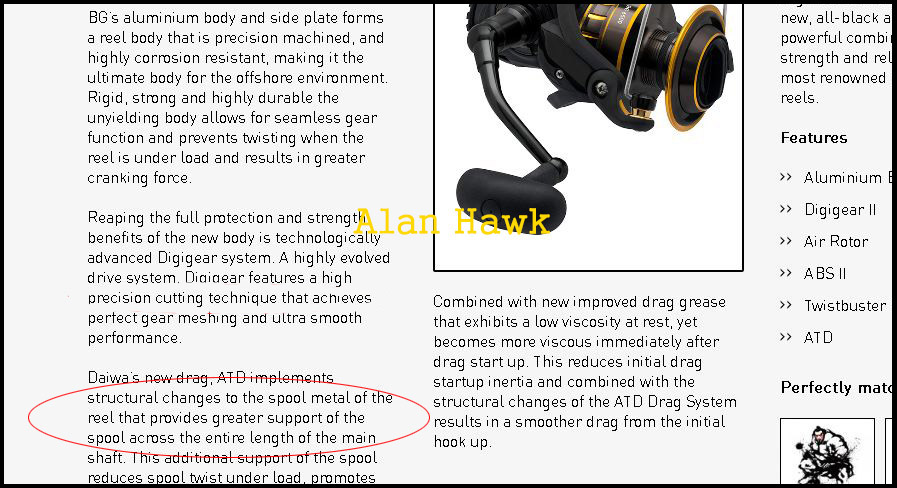

Daiwa's official Australian site states the following

They basically copied the full definition of the ATD from the high end reels and pasted it for the BG SW, which is misleading because while the ATD grease part is correct, the BG SW doesn't have the extension in the shaft and its housing in the knob which are supposed to improve the spool's support. This misleading text is a natural by-product of the persistent desire to inject this marketing trash everywhere. A few letters that are assembled to create a catchy name for a fictitious "technology", then they stamp it on reels to send people running to buy the HAGANE, XSHIP, or the DURA and ATD drag. Tell you what, I have a piece of equipment that comes with the latest RDO technology, with RDO standing for Rigid-Dependable-Oversized. Would you buy it? Congratulations, you've just bought my wiener! Keep it safe in a cool place and don't touch it lusciously or we'll have an unpleasant talk.

Behind the spool the drag clicker grooves are of a similar style to what's found in Daiwa's top saltwater and freshwater reels. This is found in the new BG sizes 4500 and up.

Same goes for the clicker tongue (blue arrow). The red arrow points the spool shims which are easily changed and well retained. A proven setup in a time when much more expensive reels still suffer spring breakages and various issues that silence the clicker. Similarly, this is in BG 4500 and up, while smaller reels have a simpler drag clicker design, which still works very reliably.

This is one sweet touch; a circular recess in the middle of the spool, and a small hole drilled right at the wall of that recess (red arrow).

The hole goes all the way through. This has not been mentioned in the literature, but I know that it's a drain where the water caught in the braid will seep to the circular recess, then it would drain through the hole. Of course it has a minimal effect and you still should never store your reel with braid on the spool, nevertheless having it still beats not having it.

The drag knob is keyed to the shaft, has its own internal clicker, and a very effective seal is mounted on it (red arrow). The blue arrow points the plastic thrust disc. Don't let anyone tell you that it's a bad thing. When they are correctly designed from a proper polymer they work great as demonstrated for years from the original Saltiga to various Catalina models, and today tens of reels have them including the reliable Quantum Cabos and even the upcoming Penn Slammer III costing up to $350. This has not been mentioned anywhere, but in ICAST show they had a large board with every part of the Slammer III individually displayed and I spotted the plastic thrust disc. The Spheros SW and Saragosa SW have metal trust discs, but they could have worked as well with plastic ones to their respective maximum drags. Speaking of which, the BG SW 8000 is rated for 15kg (33 lbs) of maximum drag which the spool produces easily, but as I've said numerous times the spool produced resistance is only one part of it. The practical maximum drag is what the reel in its entirety is able to support while functioning normally. I'd say that the practical maximum drag of the BG SW 8000 is about 12 KG (26.5 lbs) only. Don't go over that, and if you fish at that figure don't palm the spool as it would send it over the top and could cause failures.

Overall the drag is designed from premium components with Daiwa's proprietary grease, and I was very happy with it. Fought and landed many good sized bonitos, groupers up to 11 kg (~24 lbs), Black Drums in the same range, a handful of smaller sharks, and caught up with some bluefish before they moved south which ranged in the 4-5 kg (~11 lbs) region. The biggest fish fought was a single Amberjack estimated at around 25 kg (55 lbs) on 8 kg (~18 lbs) of drag, and it was no problem at all. Nothing to write home about and certainly no trophy fish, but that should cover about 75% of all sport fishing done today.

This is how the reel lays line on the spool. Commendably even, and in conjunction with the large diameter of the spool the reel casts very well. I wished I could make a little clip of casting and retrieving a spoon, but I mostly fish solo and have no one to film the cast.

More bits that are borrowed from the top range; the rotor nut is retained by a screwed down plate (red arrow), albeit without fully covering the nut since this reel is not waterproof.

The air rotor. I mentioned this quickly in the past, but once again for greater reach; the "air rotor" is a description of the design, not the material. I've seen the rotor of the BG SW being called Zaion which is not right. This air rotor is made from the standard plastic usually called graphite by the industry. The air rotors of high end Daiwas are the ones made from the long strand carbon fortified plastic they call Zaion. That said, this superb design which has been copied exhaustively by other brands creates a light weight rotor where the arches distribute loads away from the rotor arm's base, therefore more material can be cut away while maintaining higher rigidity. The BG SW's rotor is appreciably more rigid than the much beefier plastic rotors of the mid-upper range Shimanos and all the way up to the idiotic Sustain FG.

Despite being almost so, it's not an exact copy of the Zaion rotors of the Saltigas. Being a lesser strength composite, they left some of the material where it was cut off in the Zaion rotors, which unfortunately blocks access to the rotor-brake ring.

Here it is. It's the rubber ring that's engaged by a lever when the bail is opened to hold the rotor still during a cast. In some high end reels with Zaion rotor there are enough cuts to make this ring accessible to your fingertip for oiling, while in the BG SW it's unreachable without removing the rotor. I love having easy access to it because rubber rings in spinning reels dry and fall apart over time from use in the sun and hot weather, but if you can oil them regularly they will live longer. Anyway, this rotor-brake system only comes in sizes 4500 to 8000, while smaller BG SW reels don't have it. Not ideal since these smaller reels (1500 to 4000) have an automatic bail trip which makes a rotor-brake highly desirable, while sizes 4500 to 8000 have a manual bail closure which makes the rotor-brake in them less important.

The rotor has a recess for an O ring seal, but the seal is not there. Don't panic and think that your BG SW is missing a part. It has this recess because this rotor will be used in the upcoming Saltist which will have a mag-seal in the pinion and a complementing O ring in this recess. Now let me veer off the BG for a little bit;

For years I have been advising people to stay away from any reel that has a mag-seal short of the fully sealed high end ones. There is no point in buying a reel that has a mag-seal but not fully sealed. These reels can be penetrated by water easily, and in many cases even the carrier of the mag-seal itself is open from behind allowing water in! Buying one of these will leave you stuck with a reel that's not sealed, yet comes with all the hassles of caring for the mag-seal such as keeping lubes and solvents away from it, then of course when it's time for a full service you are forced to send it to Daiwa. It might have been arguable had these reels offered anything special or unique, but we are in a time where there are plenty of superb reels in all price and performance categories, and these don't have the baggage that comes with the mag-seal. With the usual disclaimer when I talk about reels that are not yet released and can have a change of specifications, the new Saltist will share 90% of the BG SW's construction, with the remaining 10% being a mag-seal in the pinion assembly and another in the line roller, an additional bearing and some cosmetics and bling, and a supposedly smoother bail wire connection but in reality the standard one found on the BG SW is every bit as good. Despite what you heard the new Saltist is NOT fully sealed, and the video where a Daiwa representative says that it has two mag-sealed bearings on both ends of the drive gear is simply inaccurate. Please note that this has been my position for many years, and it has nothing to do with the recent decision to take the Saltiga/Catalina family off my top picks due to the magnetic fluid's hostage situation as explained here. Back to the BG.

Beneath the rotor, the anti-reverse clutch. The 4500 to 8000 sizes have a full time anti-reverse, while the smaller reels will have a switch to turn the anti-reverse on and off. Examining the clutch I initially saw nothing out of the ordinary, until I looked closer...

In a remarkable surprise, the anti-reverse clutch has individual metal springs for each of the brake cylinders!! The great majority of the anti-reverse clutches in spinning reels have the generic design where plastic V springs are moulded into the cage, and those activate the brake cylinders. Those plastic springs have different life spans depending on the quality of the clutch, but ultimately they lose their elasticity and become permanently set, causing slippage and eventual failure. Few spinning reel clutches have individual metal springs, and these are always superior to other types. The individual metal springs enhance dependability, but first and foremost they give the clutch an extremely long life. They apply more constant pressure than the bent plastic springs, they compensate for wear in the cylinders, and they don't become permanently set. Don't confuse longevity with strength. The BG SW's clutch has a medium torque rating and is not for immense loads, but if used within its design limits it will last for a very long time. This is the first real connection with the original Black Gold reels, whose most known quality is longevity.

A minute later I took out the pinion's ball bearing, and was shocked again. These ball bearings are from the Japanese company Minebea. They are made in Thailand, but that's where the company makes particular sizes of bearings now. All the bearings in the BG SW are Minebea. Do you want to know how good these bearings are?

This photo is from a Saltiga I had laying around. Most of the non mag-sealed ball bearings in the old and current Saltiga/Expedition/Dogfight are the same Minebea bearings made in the same plant, as well as several bearings in the 2013 Stella SW. You will also see these exact same bearings in an upcoming $1000 high end reel of which I can't talk now. Up till a few years ago I considered Japanese made bearings to have a desired prestige, but with globalisation some top Japanese companies began making certain sizes and styles exclusively in their factories abroad, therefore I stopped whining about prestige and just appreciated the supreme quality. I wouldn't have expected in a million years that this $100 reel will have the same bearings as in Daiwa's and Shimano's cream of the crop reels, and I actually would have bet good money that I was going to find the Shanghai Mos Precision Bearings which are used extensively throughout the industry, sometimes even in reels costing up to $700.

Since these are premium bearings, I decided to go the extra step of removing the snap rings retaining the shields to check on the lubing.

Naturally for such quality bearings, I found them to be very well lubed from the Minebea's factory, so I put the shields back and left them alone. High quality bearings are made from stronger alloys, these alloys resist corrosion better, but most importantly they have tight tolerances which reduces internal play and vibration keeping moving parts in perfect alignment, in addition to extending the service life of the bearing itself. Another pleasantly surprising feature in this reel, and one that's obviously geared towards longevity as well.

To access the gearbox the plastic rear body shield (red arrow) needs to be taken off.

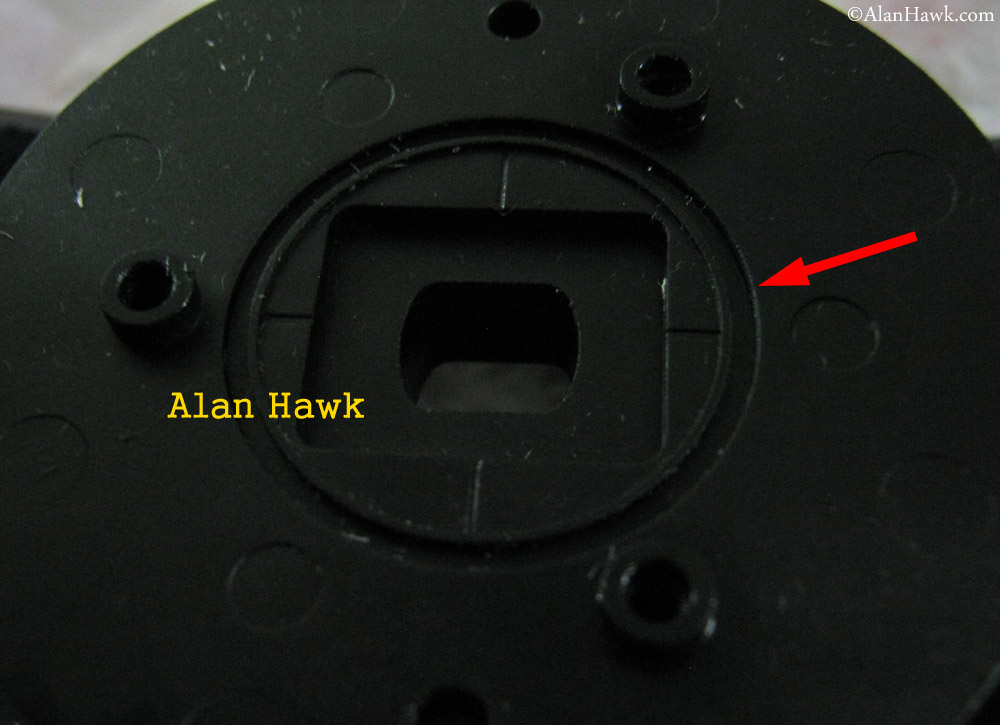

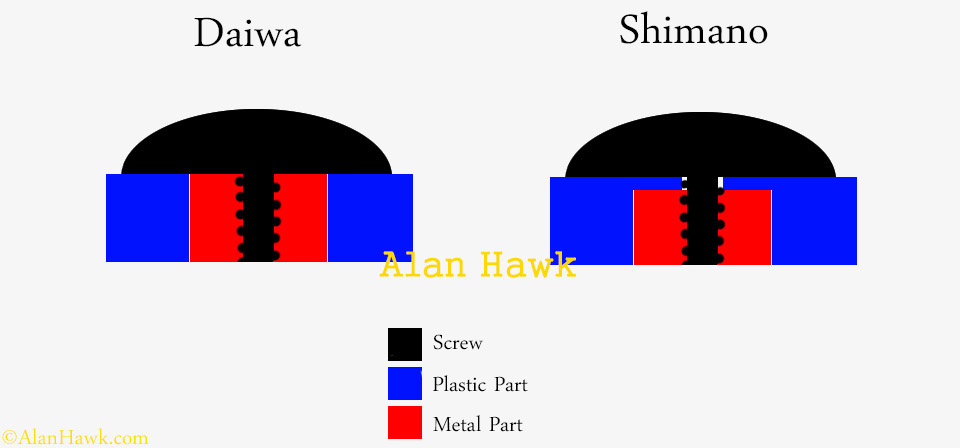

I really want to show you this. Daiwa has a very refined method for fastening plastic to metal; instead of tightening the screw against the plastic part, the metal of the frame protrudes into the plastic (red arrow) so that the screw's head will be tightened against the metal protrusion instead of against the plastic part, and the edge of the screw's head holds the plastic part down without the risk of damaging it. Look at this quick diagram explaining the difference between Daiwa on one side, and Shimano and some other brands on the other side

Both styles work fine, but the difference is that with Daiwa's style if an inexperienced user was servicing the reel and overtightened a screw holding a plastic part nothing will happen because the screw will hit metal, while if the same happened with a Shimano the screw will crack the plastic part. The bail mechanism cover in Stella SW reels is the biggest victims to this, and I must have seen more than 15 cracked ones over the years. One has to admit that despite the reprehensible service strategies, Daiwa remains the most innovative company in this field.

Also to prevent panic, only three screws of the side cover have clamping washers (red arrow). The remaining two screws don't.

The side cover was generously covered in grease from factory, even inside the ball bearing recess. I've seen high dollar reels done like that for extra protection, but that's too much to ask in a budget reel. The same was done with the frame/gearbox.

The side cover has two studs which double task for alignment, and as reinforcements so that under pressure the screws won't fail and cause the gears to go out of mesh.

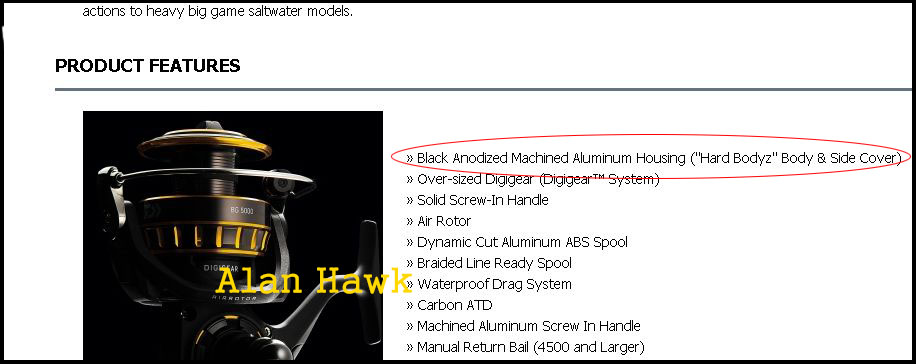

The frame, cleaned off grease to show you the casting sprues marks (red arrows). Daiwa claims that the body and side cover are machined, which is untrue. Creating a frame by die-casting then machining threads into it does not make it a machined frame, rather it remains a die-cast one.

The first part of the statement is correct though. The frame and side cover are indeed anodised. I heard your feedback about going confusingly technical, so I'll keep it very simple; traditionally die-cast parts are not good candidates for anodizing, because the casting alloy is created for fluidity so that it can easily flow when molten. In the case of fishing reels this fluidity is achieved by the addition of silicon to the casting alloy, and silicon does not anodise when it solidifies. In addition to this, cast surfaces are too porous to behave predictably during anodising. There are ways to go around these impediments by manipulating the density of the alloy then giving the cast part a chemical surface treatment before anodising, still the finished surface will not be perfectly smooth and its colour will not be uniform, therefore this method is usually used to create black or very dark finishes. The die-cast frames of high end Daiwas and Shimanos continue to be plated instead of anodised, trading the superior protection of anodising for the shiny colours and smooth surface of plating.

I have no standardised testing for a reel's finish since scratches and finish damage happen by accident over years of use, but I look for some indicators such as the common slight finish damage in the corners of a spinning reel's foot where it attaches to the rod. I can say that so far the anodised finish of the BG SW is indeed as tough as one expects from anodising, no trace of damage to the foot, I have peace of mind since anodising never develops the dreaded "bubbling" in the finish, and the different feel of the body is perfectly fine with me. For a fun experiment and to familiarise yourself with the different feels of anodised parts, touch the reel's body then touch the spool. The spool is anodised as well, but it's machined from aluminium of high purity so it can be easily anodised in any colour leaving a perfectly smooth surface.

The drive gear, which Daiwa's representatives have been describing as follows

In this video they claim it's made of aluminium, and make a point of comparing it to a zinc gear from a competitor. Let me repeat this again to preemptively shut down any excuses; this is not a casual mistake or misspeaking, because they bring another gear then very deliberately say ours in aluminium and the other is zinc. In reality, the second I held the gear of the BG SW I had no doubt in my mind that it's zinc. With my educational and professional background in addition to decades of fishing, the sheen and feel of zinc were unmistakable to me. Yet being very patient I waited until I got my retail purchased production reel, and now density and acid tests confirm beyond doubt that it's zinc. This rubbish needs to stop. There are many such cases where wrong information was given, and it's not limited to one company. I have for instance a video where a Shimano marketing manager erroneously claims that the Sustain FG has a metal body and side cover, which I shall post as well but in another place not to clutter this review. Bottom line is, whether these were innocent mistakes or otherwise, it needs to stop because facts will always come out and it will only hurt the company's image. Of course the gentleman in the above video is at no fault whatsoever, rather it's whomever delivered that bad piece of information to him and his colleagues is the one at fault.

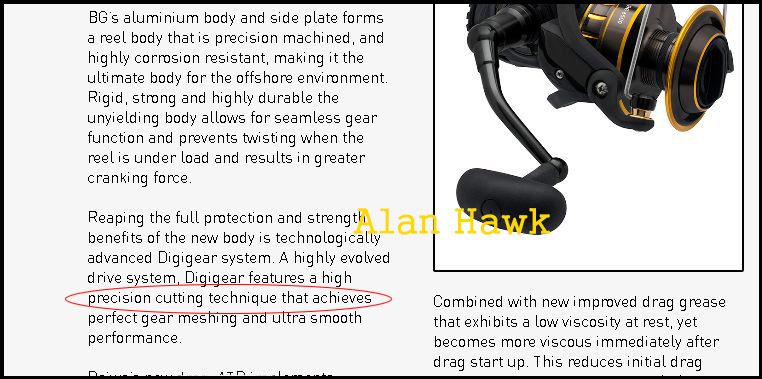

Then we move to that whole "Digigear" soup opera. I explained it in the past, but now I will update it since Daiwa continues to play fast and loose with the term. In the past there was the original Digigear which was a precisely machined drive gear of the wrought alloy C6191 aluminium bronze. Then Daiwa renamed that to "Hyper Digigear", and introduced the "Digigear II" which was a similarly machined aluminium alloy drive gear. Now it's wild west and there are no rules anymore. They still describe "Digigear" as being machined as you can see in the above photo, but then we see this

The RX is described on Daiwa's Australian site as having "Digigear II" when the gear is cast zinc. This is not a typo, rather it's one example for you, and other reels with a cast zinc gear are also described as having "Digigear II" on that site.

Daiwa France and Germany have a completely different way of classifying it;

They call the machined C6191 "Hyper Digigear".

Then they call the machined aluminium "Digigear II".

And they call the cast zinc "Digigear".

That might look more organised, but sadly it still describes a basic cast gear as Digigear. On the USA site though they just call everything from C6191 to Zinc "Digigear" and leave you guessing. So the new rule is; there are absolutely no rules and the only advice I can give you when you want to know what gear is in which reel is to email me. Back to the BG SW

No, the drive gear of the BG SW is not cut. It's a cast zinc with a machined stainless steel axle.

Casting sprues marks

And I'd LOVE to see a machine "cutting" these numbers. Again, having grooves and recesses machined into a die-cast gear does not make it a machined gear as long as the disc and teeth were formed by die-casting. This is a cast gear by every definition.

That said, it is a colossal gear. Photographed here next to the spool to show the scale, and remember that this is an extra wide 8000 size class spool! I don't keep a precise record of this data, but off the top of my head I believe I've only seen two other gears that were larger in all spinning reels. The teeth size of the BG SW's gear though is unmatched. There has never been a drive gear of a regular production spinning reel that has equal or bigger teeth.

Those gigantic teeth are quite precise. Look at the contact area between the teeth of the drive gear and pinion, being easily 80% of the tooth surface as can be seen from the meshing marks.

The reel was fished for about 90 hours on both sides of the Atlantic, and that's how the gear looks after that mileage. No chips or cracks, no dents, no warping, no volume loss, and barely a difference in reflection on the contact surface. On a scale of 5, where 5 is the very top, I'd give the wear rate of this gear a solid 4 which is something I've never given a cast zinc gear before.

A quick explanation of gear geometry, again religiously observing your request not to go crazy on technical details; gear design is more complex than many think. Each train needs to be examined individually in order to determine its efficiency, strength, and durability. In an application where there are general similarities and some repeated patterns, we can make some very loose rules of what to expect from a particular train, but when these patterns are broken expectations should be erased and a proper understanding of the individual case is required. A larger diameter drive gear allows for two things; the first is larger teeth, meaning less stress per area unit, leading to both more resistance (strength) and less wear/galling. The second thing that a larger drive gear allows for (in a hypoid setup) is the reduction of the spiral angle of the pinion's teeth without a reduction in gear ratio, which is greatly beneficial. The bigger the spiral angle is, the more sliding there will be as the geartrain operates. More sliding means more wear, greater loss of power, reduction in transmission efficiency, and in a spinning reel it translates to a loss in what is colloquially known as pulling power. Of course these remain "potential" benefits that a maker can either utilise through an optimum gear design or not, and Daiwa has superbly utilised it here, creating a low cost "pot metal" gear that easily outperforms more expensive trains that are not optimally designed or manufactured. After all Daiwa's "pot metal" gear in the 1981 Black Gold is undeniably still setting records in longevity and toughness.

The gear's axle is male, which is thinner than female axles, allowing for a smaller offset and even more efficiency, although this wasn't fully utilised since they sleeved the axle with the gear material for solid connection, thus increasing the overall diameter in the process (blue arrows). The red arrow points an O ring that pushes against the edge of the oscillation gear, acting like a soft brake on it to both prevent noise and maintain its full engagement with the drive gear for instantaneous response without play.

The machine cut brass pinion is equally substantial, meshes accurately as demonstrated earlier, and the strength of the alloy can be felt as the rotor nut is tightened against the solid threads in the other end of the pinion.

The pinion spins on two ball bearings, and on the inner end behind the bearing there is this washer (red arrow). This design bit comes straight from the Saltiga, where this washer fits inside the frame's mid-post and isolates the main shaft from the pinion when the reel is under load and the shaft is under multi-directional forces. In the Saltiga this washer represents half of the floating shaft system, in the BG SW the shaft is not floating but we get this half measure to help.

A close up on that washer.

It does work indeed. You can see the difference between the matte colour of the part of the shaft that is in contact with the pinion (left of the red arrow), and the shiny colour of the part that is insulated from the pinion by the washer (right of the blue arrow). A semi-floating shaft is nothing to complain about in a $100 reel where nothing of that sort was expected at all.

The oscillation gear spins on a ball bearing, and in a continuation of the very large gearing theme, the teeth of the oscillation gear are high, deep, and thick to match the rest of the drivetrain.

The oscillation block is attached to the shaft by a factory set screw (red arrow) that should not be removed. The shaft needs to come out in one piece.

And to reduce friction under load and stabilise the oscillation block, it is mounted on a stainless steel rod (red arrow) on which it slides smoothly back and forth.

Sizes 4500 and larger have a mechanical backup anti-reverse. The wire spring on the drive gear (red arrow) goes into the stainless steel dog (blue arrow), and if the gear begins turning backwards the dog would come down and engage the stainless steel ratchet (green arrow) mounted on the pinion to let you fish normally until the clutch works or gets repaired, or you can just ignore the clutch and continue fishing forever with this ratchet anti-reverse if you like. I disabled the clutch and tested this backup system successfully to the maximum drag rating, which was a redundant test considering that this backup comes directly from the big Saltigas and Stella SWs. There is no comparison between this back up and the "toy" backup found on many other reels, some costing twice as much, where a plastic lever on the frame's flange engages teeth moulded into the back of the aluminium rotor in case of a clutch failure. Let the clutch slip on those reels while you're hooked to a proper fish at high drag setting and the backup will not only break, but it could jam the rotor making the reel useless. This is based on past experience, not deep thinking in my armchair.

A closer look at the dog. It sits on a brass washer for smooth reliable function.

The BG SW has a novel design where the right side ball bearing of the drive gear is free-floating instead of having a stop in the frame. This allows for a very close shimming of the gear from the other side for maximum gear contact, and as a bonus it results in the reel having minimal handle play out of the box. The downside of this design is that it makes the reel a real pain to disassemble and reassemble. The bearing is attached to the drive gear via a spring clip (red arrow), which needs to be taken off with tiny tools before the components of the gearbox can be taken out by sliding them at awkward angles simultaneously. This requires you to have 4 arms to disassemble, and 6 to reassemble since in the assembly you'll be doing it all again but while trying to insert the wire spring of the backup anti reverse into the dog then struggling to insert the ball bearing from the opposite side without the drive gear's spring popping out of the dog!! I really hated working on this reel, but thankfully you don't have to go that deep to lube it as you can do it just by opening the side cover while everything remains in place.

The body cap has an O ring seal (red arrow) to keep water out. The reel is not fully sealed by any means, but it has good protection against heavy splashes.

The bail arm (blue arrow) is plastic, made of thick sections and did not bend at all up the to maximum drag. It rotates on a low friction synthetic washer (red arrow) for a perceptibly smooth bail opening motion.

The line roller runs on two polymer collars (red arrows). This is interesting, because they tried something similar in the original Saltist and I was unrelenting in my criticism for its poor performance, but for the past few years they began experimenting again with a different design using Polyphthalamide as the material, and changing the shimming so that the two collars become a single unit with roller then the three of them spin on the roller's shaft for a smaller contact area and less friction. High end Daiwa reels such as the Expedition have had one of these in conjunction with one bearing in the roller for the past couple of years, and it worked well enough for them to go with two of these Polyphthalamide collars in the BG SW. I sharpened my teeth and was ready to give it a ripping as I did with the old Saltist, but the thing simply worked. The two collars fit snugly in both ends of the roller, they keep water and debris out, and they just keep rolling smoothly with both mono and braid.

For testing the gears I assigned a lot of time to surf fishing, because I know from experience that reeling fish and lures against the surf currents and waves is the ultimate punishment for gears. Pure strain on the gears as you reel against all sorts of continuous resistance. I needed to hit the surf for two other reasons as well, one was I had a couple of long cast reels that I needed to rate, and the other was to subject the line roller of the BG SW to continuous splashing with sandy water, then I intentionally skipped rinsing the roller while I rinsed the rest of the reel at the end of each beach day. I wanted to abuse the roller and see if it stops turning, but it didn't. Again don't let anyone tell you it's a bad thing. The setup works fine, it has been partially tested in other Daiwas, and because other brands are always "inspired" by Daiwa, the upcoming Penn Slammer III will also use a synthetic washer exclusively without any ball bearings in the roller. Again that's according to the aforementioned parts display I saw during my ICAST visit which I have to assume was quite accurate. Of course that's not to say that it will work on the Slammer considering Penn's roller alignment issue that seems to transcend models, and the disappointing spool bearing of the larger Clash that comes jammed by design as explained in its review. It remains to be seen when they go on sale and get properly tested, but that's not our subject today.

The handle of the BG SW is a screw-in type, and is of a design that's very close to the Saltiga's, with the hidden joint and embedded stainless steel threaded shaft.

The grip though is bolted in place. Finally something that resembles a $100 reel. When needed, a few drops of oil on the bolt's head should seep down and keep things smooth. Need to say here that I've seen this handle on production 4500, 5000, 6500, and 8000, while the smaller ones will have a slightly different stem.

There are hair-thin shims (red arrow) inserted between the grip and the stem to eliminate any clearances that would allow salt to deposit, and to give the grip a steady feel in the hand with zero play. These shims are calibrated at the factory for each reel individually, so yours might have a different number of them.

That's all. The BG SW has premium drag washers with Daiwa's proprietary ATD grease, it has a superior anti-reverse clutch with individual metal springs, has the exact premium ball bearings used in the Saltigas and Stella SW, a handle that's very close to a Saltiga's, sizes 4500 and larger have a real back up anti-reverse of the same design and materials found in the Stellas and big Saltigas, it has a tough anodised finish to top it off, and someone took to the time to brush the innards of the gearbox with grease then individually shim the gears incredibly close. The question then is how could Daiwa do this at this price and still make money? Two factors here; this reel has a smaller profit margin, but that will be made up in volume sales since it's cheap and has a widely recognised name, meaning it will sell in every corner of the world from the wealthiest to the poorest. The second factor, Daiwa can afford it because it has its own production facilities in China, as well as in a few other countries. Small brands owned by conglomerates contract Chinese factories to make reels to their specifications, and those factories must make a profit before the brand itself adds its own profit. Only the big true manufacturers who own large production facilities can work without that "middle-man" and offer the savings directly to us the consumers.

There are three such large manufacturers; Shimano, Daiwa, and Okuma, all are potentially capable of offering value that others can't. Seemingly Daiwa has finally acted on that potential and gave us the BG SW, and it's not hard to see that Shimano is still holding back. To demonstrate this, let's examine Shimano's counterpart of Daiwa's BG SW, the Socorro SW. The biggest Socorro SW sells for the exact same price as the biggest BG SW, $129.99 and $129.95 respectively. You already know what the BG offers, the Socorro SW on the other hand has a full plastic body, side cover, and rotor, a handle that attaches via the ridiculous hexagonal shaft, a drag with 2 tiny washers, two less bearings, and the oscillation block is left to rub against the body. That doesn't mean that Shimano is unable to offer the same value as the BG SW, but rather they don't want to, and have decided instead to give us what they want a $129.99 reel to be. I can't help thinking that Daiwa's move will force the others to follow suit, unless they want to see their customers going to Daiwa. I for example had bought the Socorro SW and took it out a few times to review it as an acceptable value for money, but then I saw the BG SW and immediately put the Socorro on the back burner.

Anyway to get back to the BG, all the numbers, metallurgy, and manufacturing specifications are there to help explain real life performance, but ultimately that end performance is what really counts. On the water the reel is smooth, casts very well, has a butter smooth drag with virtually no start up inertia, has pulling power that -relative to its speed- I rate among the top 5 spinning reels of all time, and the free spinning is certainly not something that belongs to a $100 reel. Just spin the handle and let it go, then watch it spin freely for as long as some reels that cost 5 times as much. The various sizes of the reel should cover most freshwater applications except for the heaviest jobs such as large Wels Catfish or Nile Perch, and on the saltwater side they should cover most medium to medium-heavy inshore work, most dry shore fishing, if you want to catch Halibut and Cod in Scandinavia, or like myself enjoy tossing a rigged Ladyfish to Blacktip sharks at night. Generally, as long as your target fish will not regularly exceed ~30kg (~65lbs) you should find a size that serves you well. The BG SW also has become the cheapest good quality high-speed reel available. With ratios from 5.3:1 to 5.7:1, the reels are certainly on the speedy side, and it would be great if they add speeds above 6:1 as well. Before this reel, the cheapest high speed saltwater reel of proper quality that I recommended was the Biomaster SW, and now the BG SW comes and takes its place at about half the cost depending on where you live.

To answer the question asked at the beginning, this reel is not an impostor. It is certainly worthy of bearing the Black Gold name with all its heritage. To me the BG SW is the new best value spinning reel available anywhere today, and it will be a lot of fun to sit and watch how it will steer the entire industry in a new direction, to our benefit this time.

The review is over. This was one of the hardest that I've done, because of time restrictions and the need to put a lot of use on it in the shortest time possible so I could move to the next one in the crowded queue. That taking place during the Olympic games didn't help either;

Imagine my absolute agony when one early morning I'm sitting in my comfy bed eating cookies and watching a beach volleyball game where that statuesque beauty Kerri Walsh smacks her teammate's cute tushy after scoring points, then the alarm goes off.....

......and an hour later I'm in a lousy boat staring at the nothingness, lonely and miserable, and a combination of the morning coffee and the boat ride is making me want to take a dump really bad! That's how much I love you you smelly bunch, and you're certainly worth it because for many years you followed me around and always helped with information, tips, loaner reels, and I've received so many invites to fish I can close my eyes and put my finger on a map and I will probably have a standing invitation in that country from a fisho who for some mysterious reason likes reading my boring rubbish. Keep the feedback and requests coming and let me know what exactly you want to see, please be good and do acts of kindness to those in need and tell your parents that you love them if they are still around, and always be safe on the water.

Cheers

Was this a good read? Please click here

Alan Hawk

August, 22nd, 2016

UPDATE: Since I've written this review Daiwa has released a JDM (Japanese Domestic Market) version of this reel, which has a downgraded construction. That JDM version comes in sizes from 3500-5000 only, and it has a hexagonal shaft handle attachment instead of the screw-in handle of the Export version. This review only covers the Export version. For more information click HERE.

|