Penn Clash 8000 : The Review

Hello everyone

A few things before I get to the Clash.

Getting a lot of enquiries about the appearance of the 2013 Stella SW on the top lists. If you recall, the review expectedly caused a storm of attacks and denials, but eventually Shimano admitted that the problems do exist and said my review was being studied in Japan to address them. See Shimano's official statement halfway through this old article. I allowed some time to pass then started examining newer Stellas in different sizes, and finally concluded that indeed improvements were made. I summarise them in an update at the end of its review. That's the reason why the improved reel now appears on the lists. Definitely feels good to know that these reviews can deliver an enhanced product to the fishing public, and certainly kudos to Shimano for taking action. You see, there is no shame in admitting mistakes and fixing them. Just in the past five years Shimano itself dealt with the melting drag knobs of the Saragosa F, the loosening drive gear screws of that same reel, and recalled the 2008 Stella SW because of the rusting line rollers. Flaws are a fact of life, and dealing openly with them is the right course of action.

The second matter I'd like to discuss is the new Van Staal VR reel. I've examined enough samples to become convinced that you are being misled by the claims that the VR is somehow "less heavy duty" than the more expensive Van Staal reels (including the X series). The gearing of the VR is every bit as powerful as the standard VS, the full submarine-like sealing is just as perfect without compromise, and the machined body of the VR is of the same superb quality. That's where they are equal, but then the VR has a drag that's superior to any other VS reel, the VR has a single piece housing instead of the bolted two piece housing of the standard surf VS models, the VR is easier to disassemble and maintain, it has rollers in the traverse guide that make it smoother under load, its line lay block has the S channel design similar to the latest VS-X series, and the VR is a considerably lighter reel. It's no secret that this reel was created by the same guy associated with the beginnings of VS and ZB reels, and that it was designed to outperform those two brands under the names "3 Tand Submariner" then "RK Sports Subaqua" before it was absorbed by the Van Staal company. Therefore there is no logical reason to believe that the VR is weaker, and if I have to guess I'd say these claims are an attempt to protect the more expensive reels which wouldn't sell very well if you knew how the VR actually compares to the rest of VS reels.

Now let me state clearly that the above doesn't mean that you should go and buy the VR. My tests are still ongoing in order to find any flaws or defects, and as usual I'll form a final opinion after I complete testing retail purchased pieces. I'm only saying that what you're hearing is misleading and that the VR is inherently a superior reel by design, pending the discovery of any issues. I won't be surprised if in the future they downgrade it one way or another to create an actual gap between it and the more expensive reels. Not that I need to say it, but let me repeat that I have nothing against any company, and actually VS is a part of the same group which owns Fin-Nor and Quantum and you probably know that I've given high marks to some reels by these two brands recently. It's only about truth and making sure that you are aware of my findings.

Finally, I'm changing how I work slightly. I will be reducing the number of full reviews of individual reels and instead will be posting more blog entries and allocating more of my time to answering emails. Guides such as "What reel" or "Reel Care" have proven to be popular, and since they contain answers to frequent questions the number of emails I receive was reduced meaning quicker responses to your messages. To me this is more important than individual reviews. The reviews will of course remain the centrepieces of this site, but they will become fewer in favour of other things.

Today's review is one of those cases where the review is size specific, meaning it only covers certain sizes instead of the entire model range. This review is only of the Clash 8000 and 6000, not the smaller reels which are quite different both in construction and performance.

A photoshoot

I like how the reel looks. Black with gold accents is a safe traditional choice that will always create a good result, unless something is horribly out of place.

The styling is heavily inspired by the 2010 Saltiga with carbon weave patterned sheets inserted in the spool's skirt and around the handle's opening on either side. The sheet in the spool is held by a square plastic clip, which is kinda unpleasant from an aesthetic standpoint, but it keeps cost low.

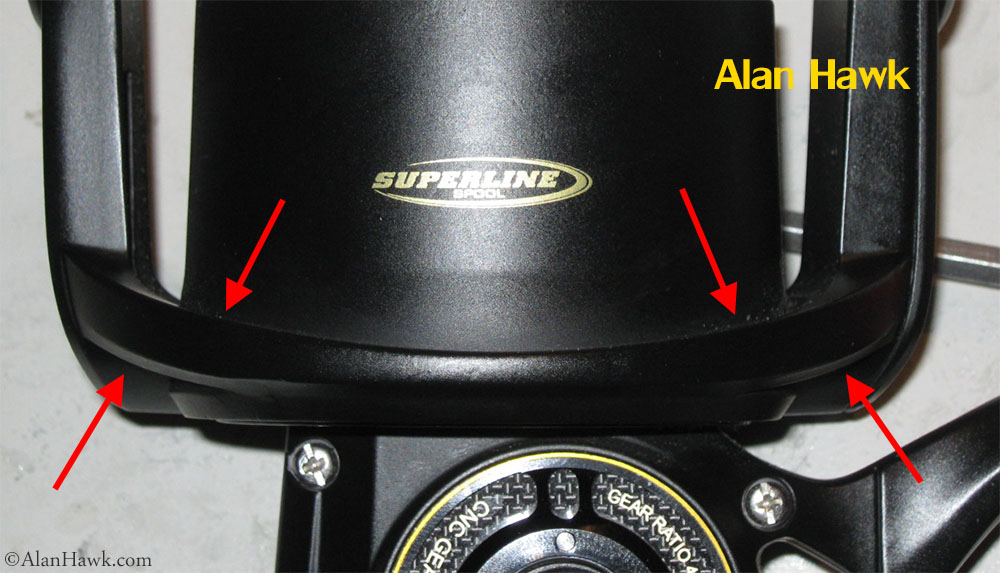

The Saltiga influence doesn't stop there. The bottom of the metal rotor is also styled after the curved compression arches of the Saltiga family. In the Clash though it's only cosmetic, since these arches are too low to play a tangible rule in redistributing loads or resisting the bending moment on the rotor's arm. Only the 8000 and 6000 Clash have metal rotors, while the smaller sizes all have plastic rotors.

What comes with it

The basic stuff; manual and schematics, in addition to a bag of extra shims to tune and adjust the line lay on the spool.

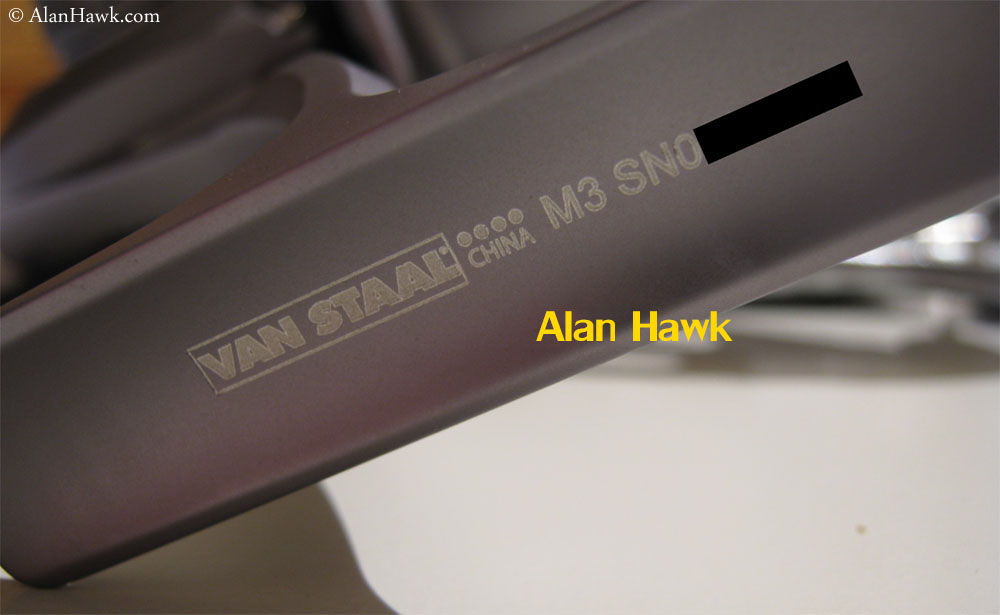

Usually at this stage I take a photo of the reel's foot showing the marking with the country of origin, except that the foot of the Clash doesn't have that. Instead...

Hidden beneath the spool is that little thing. Let's close up

"Made in China" printed on probably the smallest sticker I've seen in my life, stuck in this strange place as if someone is trying to make it incredibly hard to find and read. Putting the country of manufacture on a sticker to begin with is a highly questionable act, let alone the microscopic size of this one or where it's placed. Look at a sample of what other mainstream brands do

Shimano

Fin Nor

Van Staal

Quantum

Others do permanent stamping/marking, while Purefishing (parent of Penn) does that sticker thing on their Chinese made reels. This is not a good practice since it helps dishonest shops mislead less informed purchasers, as well as aiding dodgy sellers in less educated markets around the world pass the reels -with the sticker removed- as either "American made" or "American assembled". I am not saying that Penn is intentionally helping these people for the sake of sales, rather saying that it remains a highly questionable practice for which there is no justification. We know that the two American made Penn spinners (Torque and Z) are very visibly and permanently marked "Made in USA", therefore Penn isn't ideologically opposed to stating countries of origin or anything. Let's try this; Penn is owned by Purefishing, which in turn is owned by Jarden Corp. It operates in China as Pure Fishing (Guangzhou) Trading Co., Ltd, and they contract factories such as Haibo Machinery and Foshan Nanhai Zhongyu to make their reels. There you go, now everyone knows, so you can drop that hidden micro sticker thing and do what everyone else does.

Moving on....

The reel is priced to compete with Shimano's Spheros SW, so I will be making comparisons to it. Finding the correspondent size Spheros SW is tricky but not that hard. Speaking of actual capacities and not the advertised numbers, the Clash 8000 holds a tad more line than the Spheros SW 10000, but holds way less line than the Spheros SW 20000. It also has a published maximum drag of 30 lb which is very close to Spheros SW 10000's 27 lbs of drag, while way below the SW 20000 which has a published 41 lbs of drag. Therefore the SW 10000 is the appropriate size for comparison with the Clash 8000.

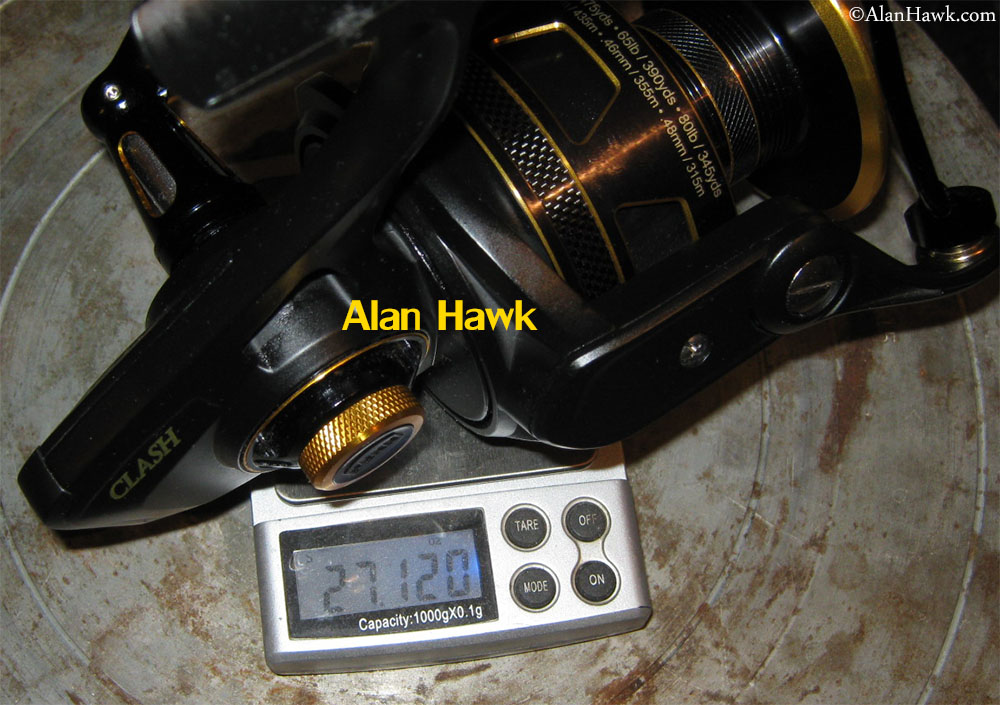

The Clash 8000 weighs 27.1 oz (768 grams), while the Spheros 10K weighs 25.3 oz (717 grams). Shimano wins this one. Also worth mentioning that the Clash is not a free-spinning reel, rather it feels unusually tight to spin, and this doesn't change with use. Will come back to this later.

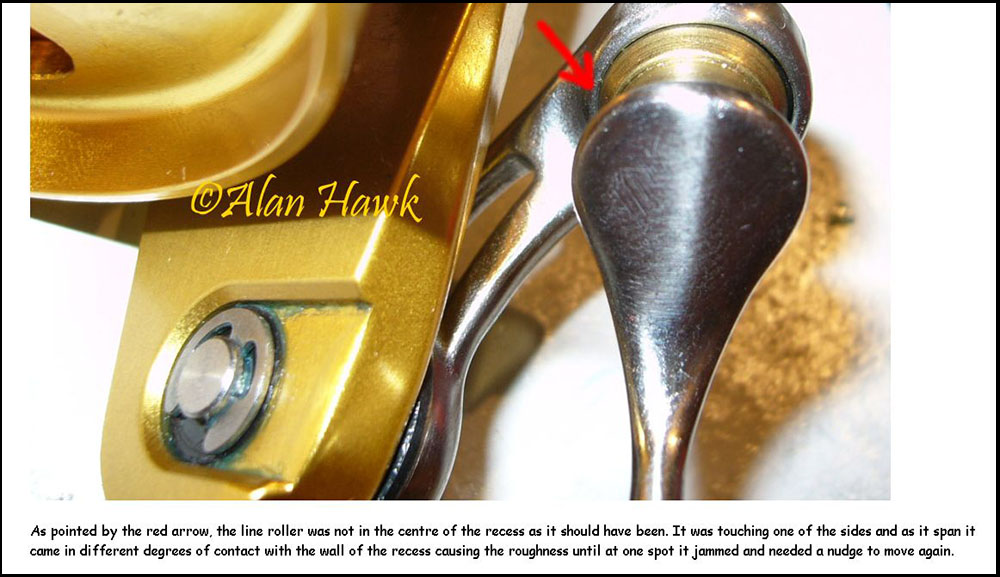

Spooling the reel, I immediately noticed a weird sound. After isolating everything else I pinned the sound down to the line roller. Listen to this video demonstration of the line roller when turned with a piece of line

The bloody line roller was making rubbing noises right out of the box. A good start indeed!

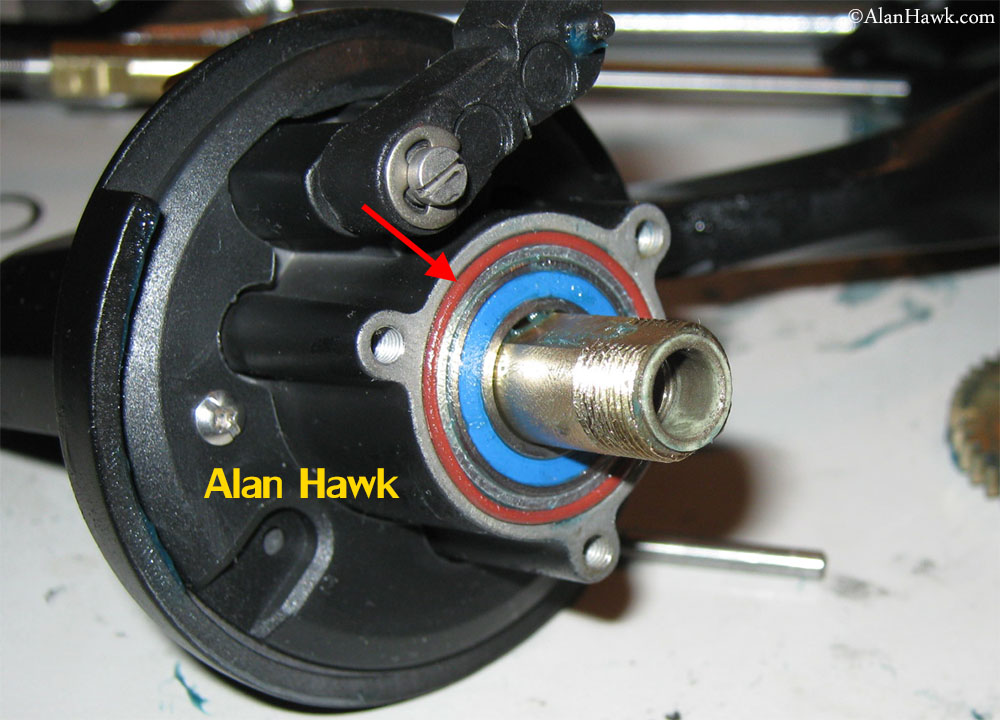

Disassembled it to see what's up, and it looked like a basic setup with the sealed bearing (red arrow) running quietly.

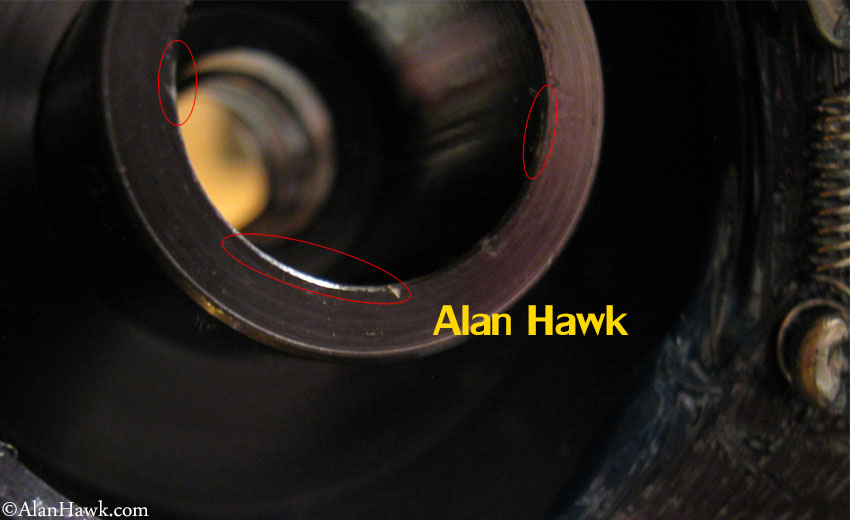

Upon further inspection

It turned out the roller was rubbing against the frame of the bail arm. The marks are hard to capture on camera but you can see them if you look closely.

Later I discovered scratches on the line roller itself where it rubbed the bail arm.

It wasn't hard for me to figure out what was going on. The line roller assembly has a guide post that's supposed to automatically centre the roller in its recess as the assembly screw is tightened, but due to the sloppy manufacturing tolerance the guide post has too much play which allows the line roller to touch the sides of that recess. Instead of the line roller being forcibly centred every time a reel is assembled, in the Clash it's a matter of luck depending on where the roller happens to be at the decisive moment the assembler tightens the screw at the factory. Based on that, I simply needed to use the tips of my fingers to centre the line roller as I tightened the screw, and the roller then spun freely and quietly.

I needed to investigate that matter further, so I managed at one point to locate someone who had 4 reels in stock and made the drive to see for myself. Two of them were alright, one rubbed like mine did, and the fourth rubbed much worse. I adjusted the rollers of these two reels as I did with mine as a favour to the guy and left knowing that it's not an isolated issue. On my way back though I remembered something weird... I mean REALLY weird....

This is a screen capture from my review 5 years ago of the Penn Torque. Read and see the issue I found then. I really didn't know what to make of this, but it was certainly disturbing, Anyway, need to mention here that the Torque was later redesigned and the issues fixed, and it has been featured on my top lists since then along with the reintroduced Penn Z reels.

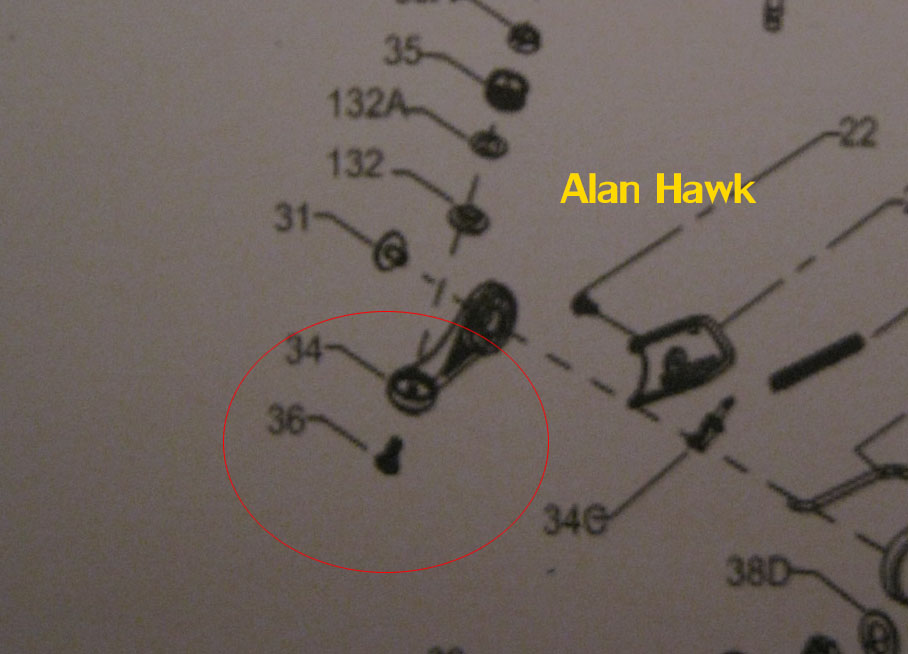

I can only advise you to check your reel for the free and silent rotation of the roller, and if yours has an issue look closely to see where the roller is at so you'd know where it needs to go. For example the gaps in above photo of a Clash show that the roller needs to be pushed slightly up as you tighten the screw.

After sorting out the roller, this is how the reel spooled the braid. Quite nice and even, and I didn't need to adjust shims or anything.

After my first fishing day though I noticed that the line roller assembly was becoming loose. Initially I thought it was a classic case of the screw getting undone and tightened it, but then the play came back on my second trip. This video shows that play

The confusing part was that the screw didn't move. When I tightened it the first time I noted that the slot in the screw's head pointed at 10 O'clock, now the screw was still at 10 O'clock yet the play in the assembly was back.

The screw threads had enough loctite on them therefore it indeed never moved, but I noticed that the screw had a serrated head (red arrows)

That was it. Someone decided to use a serrated screw and tighten it directly against the alloy bail arm, not realising that the sharp serrations on the hard screw will chew on the alloy of the arm. The above photo shows the severe damage the screw caused and how it damaged the finish then dug into the back of the arm, causing the assembly to become loose with use. Firstly, the alloy of the bail arm is softer than it should be, and secondly they should have put a hard washer between the serrated screw and the alloy arm anyway. The washer acts to distribute the clamping load over a greater area, and it keeps the sharp serrations from eating into the alloy.

And no, my reel isn't missing any parts. It was designed like that with the screw going directly against the bail arm's metal. I am at a loss for words here. Seen many design fault in my life, but this has to be one of the most elementary of them all, and it makes me wonder if they do field test their reels then examine them or just use them for the promotional videos where people hired by the company itself do a few casts then tell us how great the reels are. And in case you didn't know, this reel won "Best Saltwater Reel" award at ICAST, which should give you a good idea about the value of these awards. Anyway, do yourself a favour and find a thin stainless steel washer and place it between the screw and the bail arm, otherwise with use the line roller assembly will become loose as seen in the video above.

Speaking of awards, let me digress for a little bit.

I am still perplexed by why anyone would believe that show awards have any value or that they somehow negate the factual information and demonstrable faults in a product. I would understand it had these awards been given by a panel of expert fishermen and tackle engineers who take all the reels on display out and methodically test each then sit and evaluate the performance and weigh the faults against their bulk of knowledge of fishing gear before giving the awards. But since this isn't even remotely the case, these awards need to be viewed in the same light as the magazine/website "reviews" written by people who are sponsored and endorsed by the industry. You know these reviews of course, the ones where the reviewer will always conclude that the reel is great, pose with a big fish, and for "realism" and "objectivity" he would list negatives such as "the reel is too powerful for the poor fish it takes the sport out of it", "the cost makes it only accessible to those who appreciate fine quality", or make up a fictitious objection that no one cares about such as "it should have come with a shallow extra spool" or "I'm disappointed the reel's carrying bag didn't have a stitched image of a prolapsed anus". I spent the past 17 years trying to make people see the difference between the industry's promotional trash and real evaluations, but sadly people still fall for these just like they keep falling over and over for the garage operations selling rebranded shelf reels as locally made fine items.

The drag knob has a protective seal to keep water out.

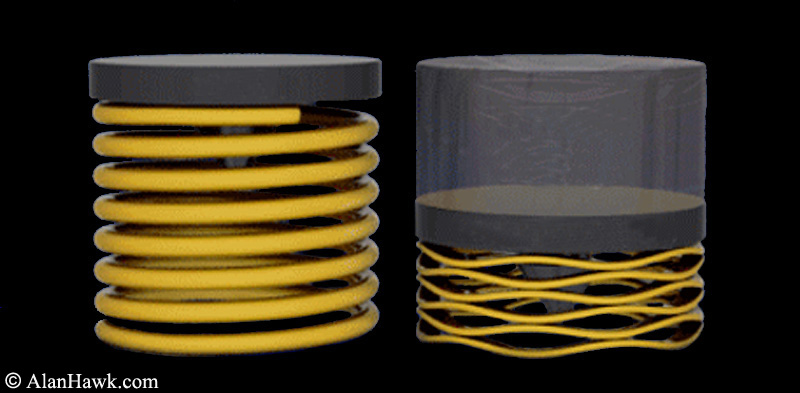

Inside the knob a "wave spring" is used. It has been about three years since I last explained this, so let me do it once more;

The main job of a spring in a drag knob is the uniform application of pressure during drag runs. The spring also partially compensates for heat expansion of metal drag washers as things heat up. Traditionally coil springs are used in spinning reels, but for the past few years "wave" springs have been appearing in some reels. Wave springs have better lateral stability and load deflection behaviour than coil springs, in addition to being roughly 50% smaller than coil springs that produce the same force. At higher drag settings a traditional coil spring fails to maintain a linear force progression, so for example instead of the drag pressure increasing by 2KG for each turn of the knob at lower settings it increases by 4KG for each turn at higher settings. A wave spring on the other hand maintains a more linear drag progression, and in addition maintains better elastic characteristics when compressed which produces better consistency and compensation for volumetric changes caused by heat.

The drag is different than the usual deal. It is a top stack arrangement, but with keyed brake washers (red arrows) so that the washers rotate with the spool. This way both sides of the brake washer produce braking force against the adjacent metal washers, as opposed to the standard arrangement where only one side of each brake washer is utilised. Keyed brake washers have been used previously with success, but that was in low stress systems with very large washers located beneath the spool where a reduction in parts is essential to keep the spool from mounting too high on the shaft. In the Clash it's done only to reduce the number of brake washers and therefore cut costs, and you're left with fewer washers that wear quicker due to being worked from both sides. How do I know about the wear issue so soon? Easy, Penn has already used that exact same drag in the Battle II and the Conflict, and I've spent enough time with the Battle II to know that the washers do wear quicker. It's no more than a cost-cutting measure brought over from an entry priced reel to this $260 reel.

Drag longevity notwithstanding, the drag performed very well for what I used it for; groupers on bait up to ~12kg (~27 lbs), slightly bigger Amberjacks on jigs, and miscellaneous bait fish caught trolling spoons for the benefit of another reel that I was testing. I also successfully landed a few tuna species in the 15-20kg (~45 lbs) class. The drag would heat up and warm the spool during longer fights, but it never became problematic or disruptive. I would attribute this to the wave spring, and strongly advise anyone making saltwater reels to incorporate one, except for reels with felt drag washers since heat destroys felt anyway.

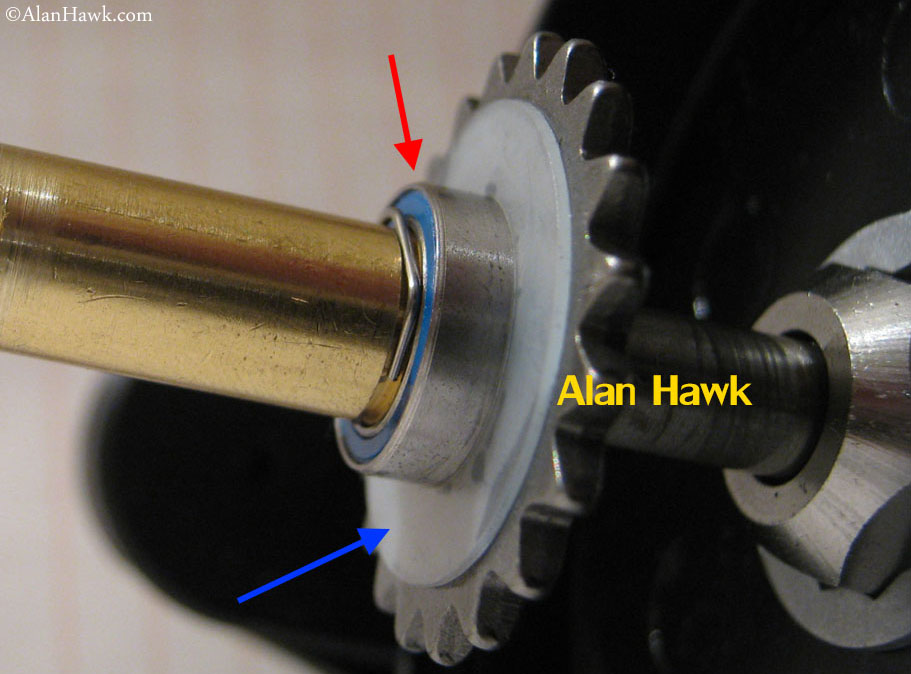

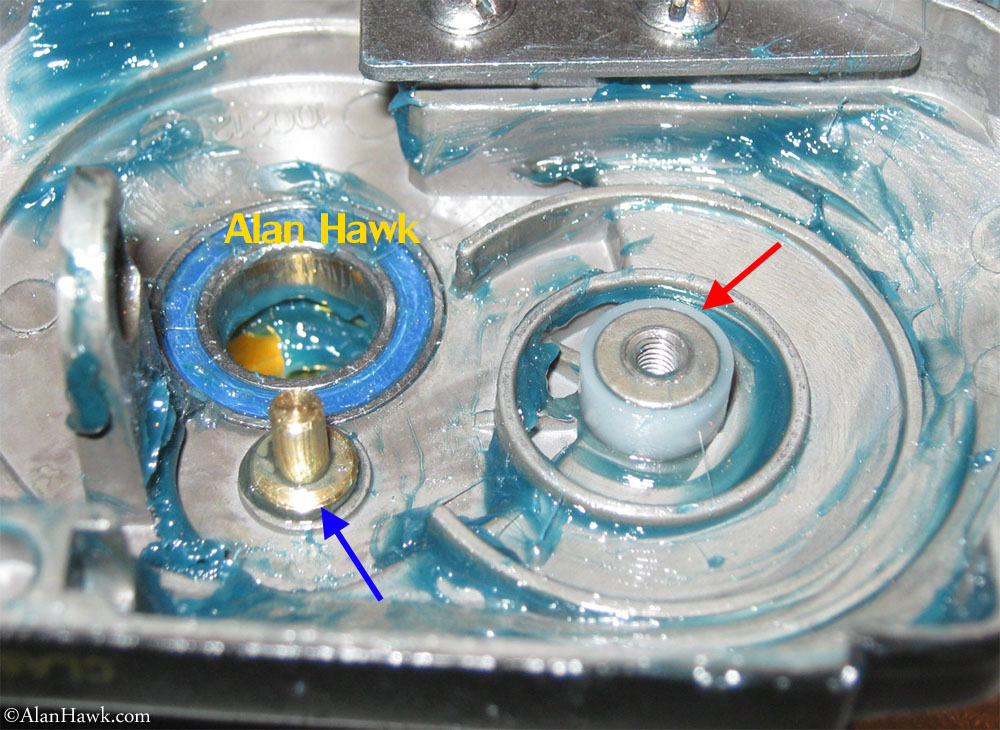

Beneath the spool lays another quirk. They put a ball bearing (red arrow) for the spool to run on, except that the bearing is prevented from spinning by the spool shim (blue arrow). Yes, they actually placed a ball bearing, then used the outer race of the bearing as a hub for the shim which rendered the bearing inoperable. This basically forces the spool to slide against the static bearing instead of spinning with it. Go ahead, remove the spool on your reel, hold the bearing and try to spin it and see what happens. If you finally manage to make it spin, the entire shim would spin with it which can't happen when the spool is on since the spool rests on the shim and keeps it still.

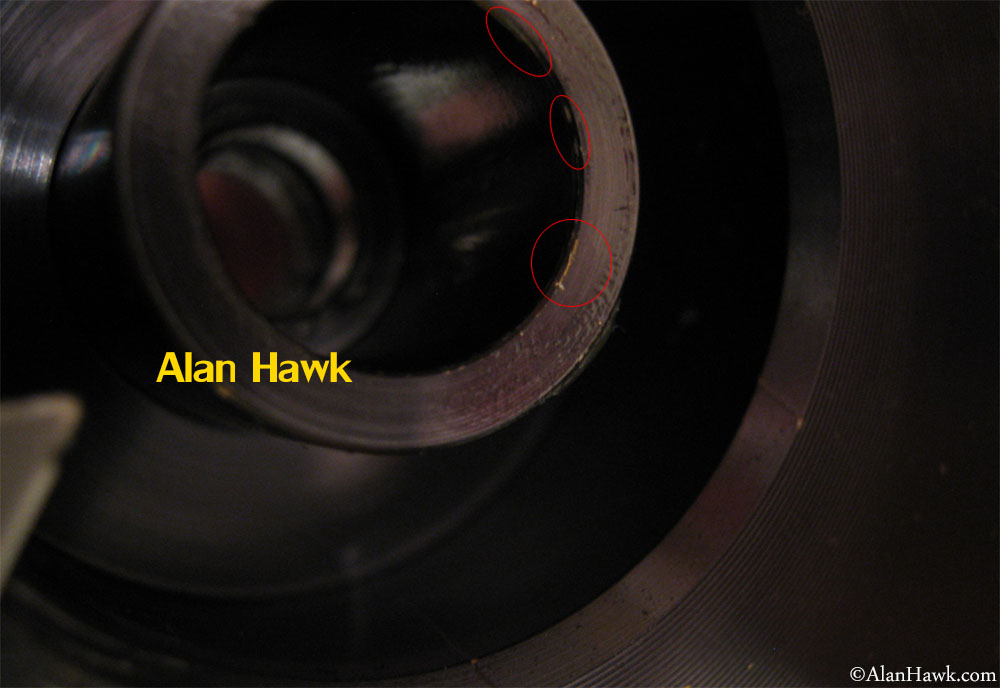

Because the metal of the spool rubs against the static metal bearing, the finish on the spool will show damage that increases with use.

Yes, this is exactly the kind of damage you'd get in this situation. Only to the edge and not spread over an area equalling the bearing height as you might imagine, since the spool needs to have zero tilting for a damage mirroring the bearing's height to occur. Again I'm left scratching my head as to how exactly did no one notice that using the bearing to fix the shim would hold the bearing still. This can't be fixed by simply enlarging the hole in the shim because then the shim would move around and the base of the spool could slip through it and rest directly on the metal clicker gear. The bearing needs to go and a synthetic bushing placed there instead. There is no other fix without a drastic redesign. Unlike the line roller issues, this fault doesn't interfere with the operation of the reel so it's not a major deal. Just highlights the quality of engineering that went into this reel, again in a feature copied directly from entry priced Penn spinners which is a very common theme in the Clash.

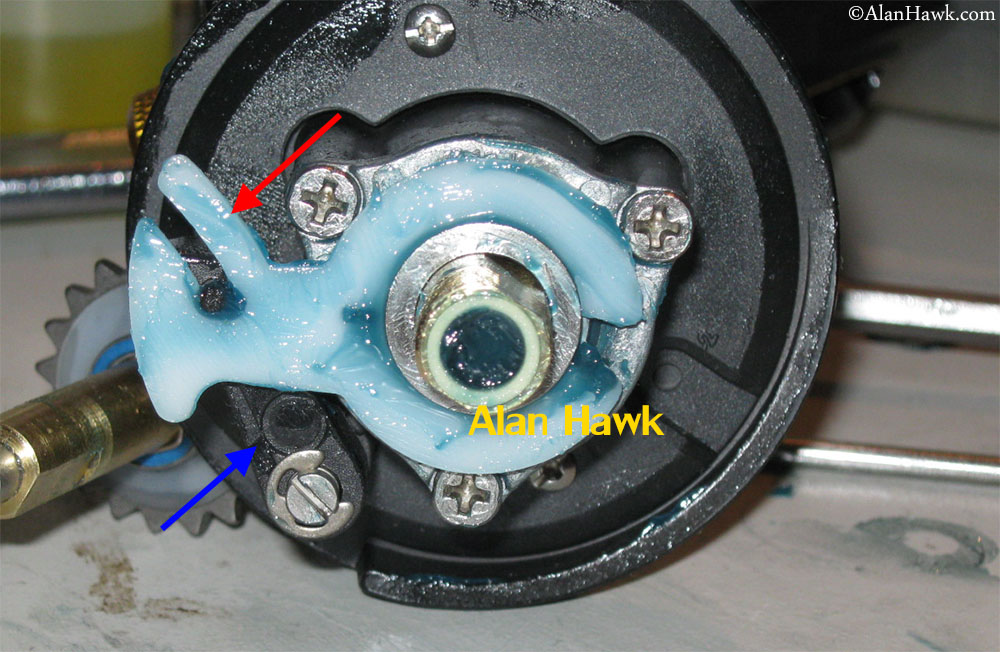

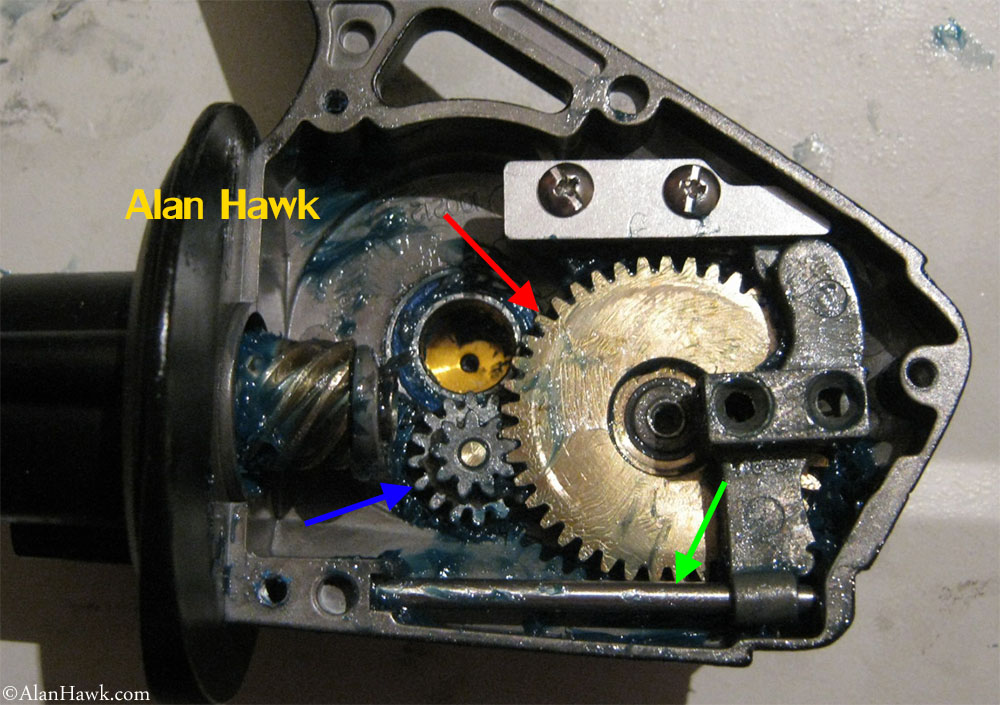

Beneath the rotor there is a backup anti-reverse system. If the one way roller fails and the pinion began to spin backwards, the actuator (red arrow) would push the plastic lever (blue arrow) outwards....

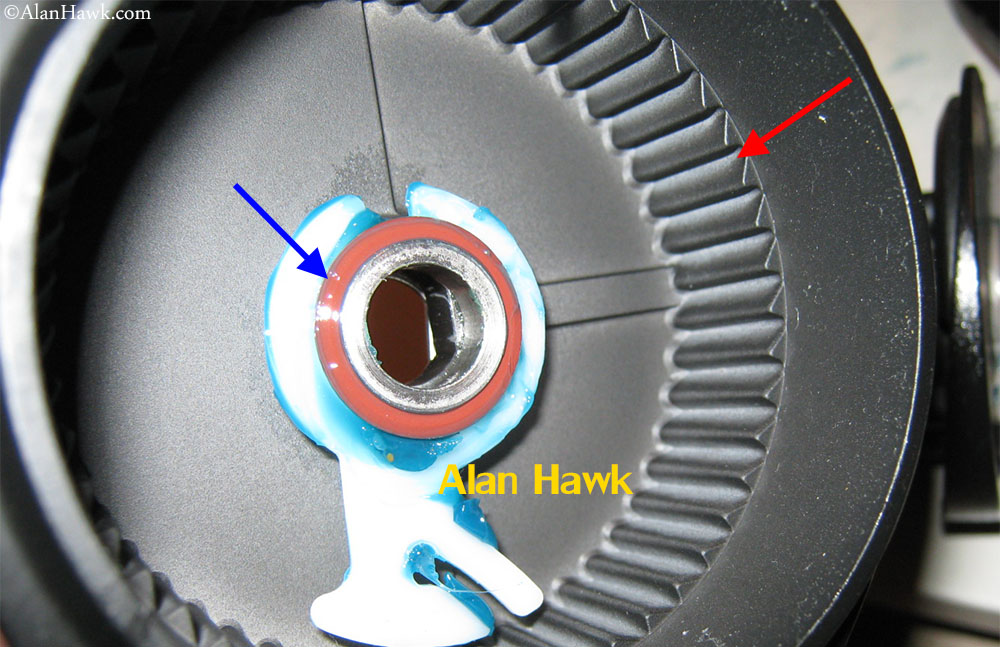

And that lever would then engage the teeth in the back of the rotor (red arrow) and stop it from spinning backwards. In the above photo I moved the actuator seen in the previous photo to the back of the rotor to show the rubber seal (blue arrow) mounted on it to protect the pinion assembly from water intrusion.

With the actuator out of the way, the rotor brake ring (blue arrow) is visible. When the bail is opened for a cast a lever engages this rubber ring to keep the rotor still during the cast. It works very well. Also seen is a polymer washer (red arrow) inserted into the pinion to reduce friction between the pinion an the main shaft in a common setup that I call "the poor man's floating shaft". The green arrow points the auto bail closure ramp, which sadly is an integral part of the body that can't be removed. I know it won't cause premature closure because of the strong rotor brake, but that annoying ramp gets in the way 50% of the time when I try to open the bail only to find that I hit the ramp and need to spin the rotor before I can open the bail.

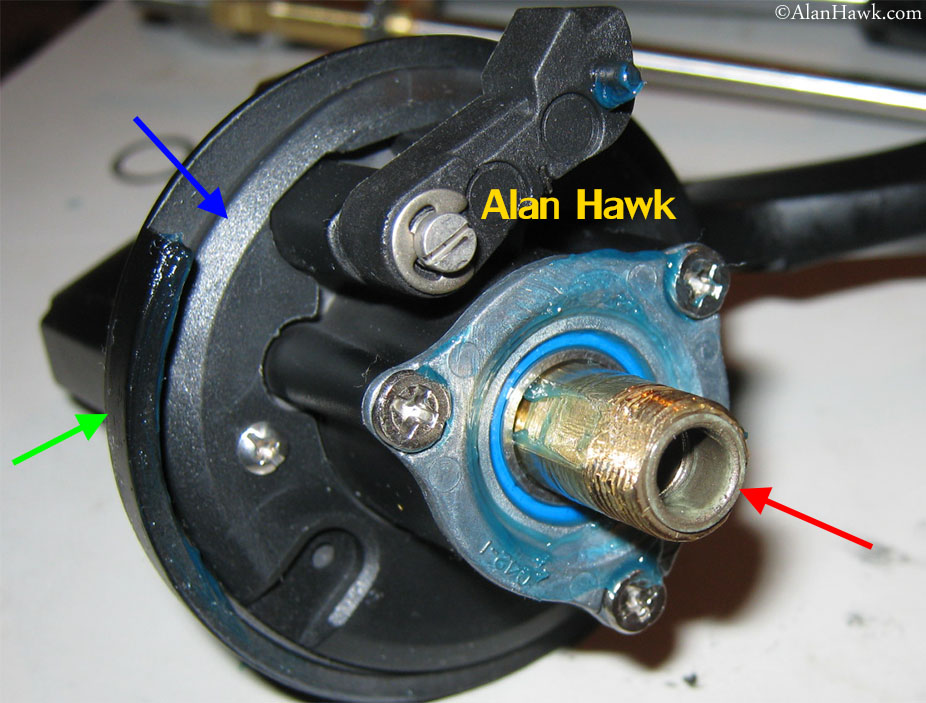

Beneath the retainer ring there is another rubber seal (red arrow).

To get inside the gearbox, the plastic rear bumper needs to be removed. That bumper doubles as a retainer for the guide rod you'll see in a minute.

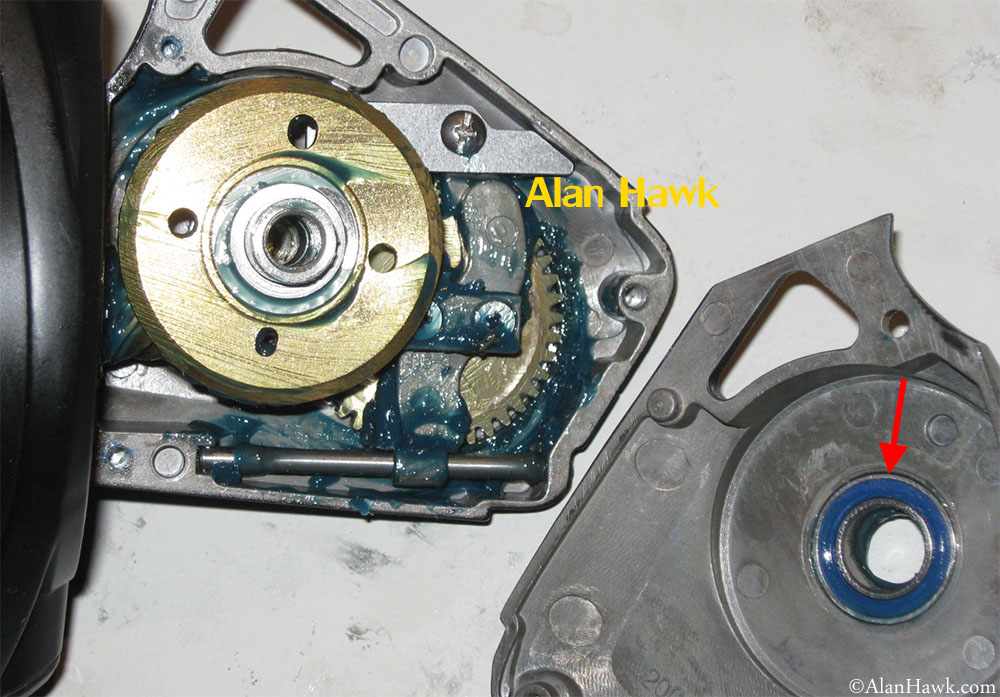

Side cover off, and the red arrow points one of the sealed ball bearings of the drive gear. All the bearings in this reel are rubber sealed. Will discuss that further down.

Removing the drive gear is quite tricky and requires a bit of acrobatics since the screwed down oscillation gear (red arrow) traps it. That oscillation gear is brass and seems well made. The green arrow points the traverse block guide rod I mentioned a few lines earlier, which is retained in place by the plastic external bumper. The blue arrow points a zinc reduction gear which acts as a link between the drive gear and the oscillation gear to slow down the oscillation stroke. The spool of the 8000 does one full cycle up and down per 5 handle turns, which is slower than the common standard of one spool cycle per 2 or 3 handle turns. The slower spool stroke lays line coils closer to one another on the spool and theoretically improves casting distance, except that there are many more factors involved in a reel's casting performance and a single factor can't give the whole picture. I did not find the Clash to be an exceptional caster. Seemed quite standard to me.

Mounts of the parts discussed in the previous paragraph. The reduction gear spins on a brass post (blue arrow), and the oscillation gear on a synthetic bushing (red arrow). Considering the slower speed of the oscillation gear this is a durable setup that should last a very long time.

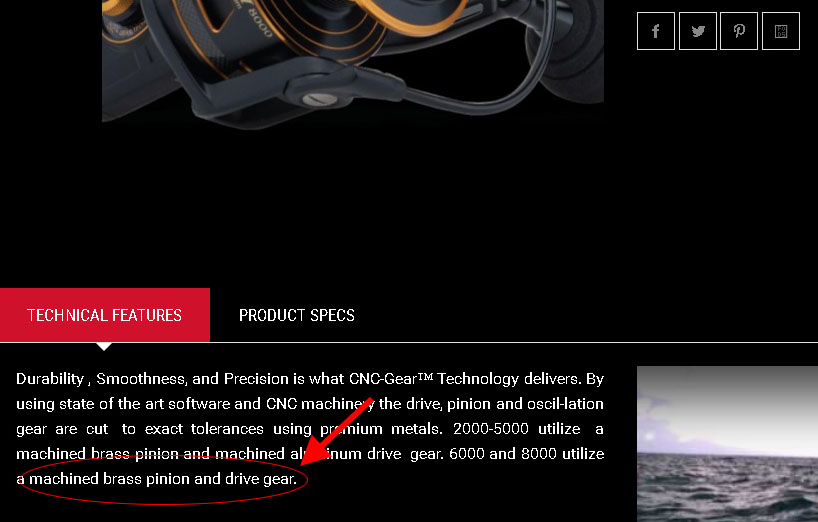

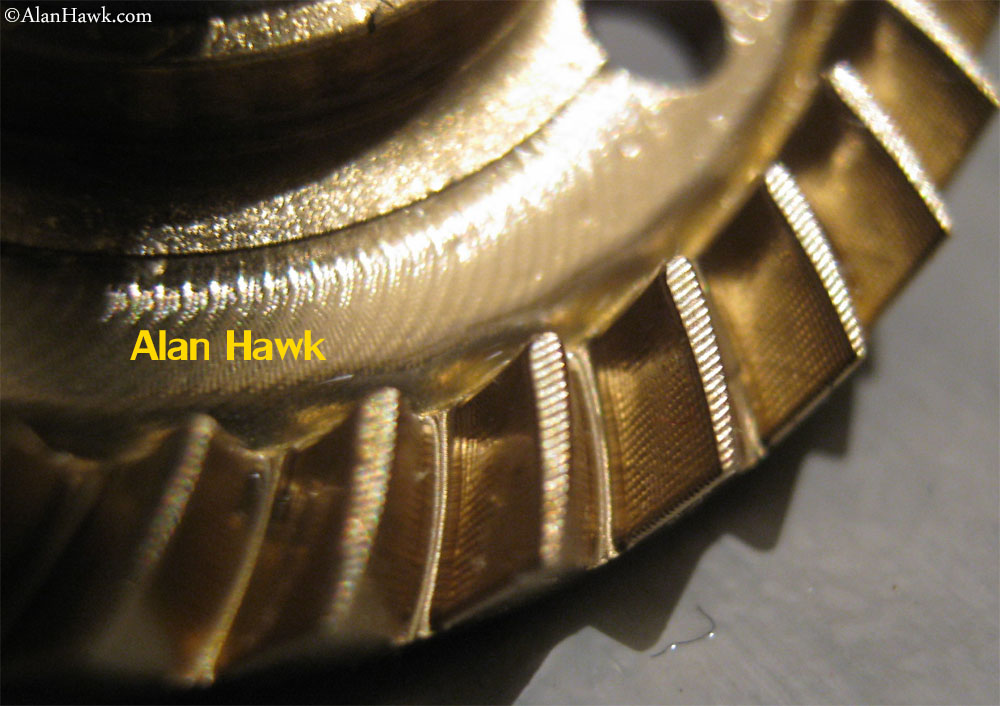

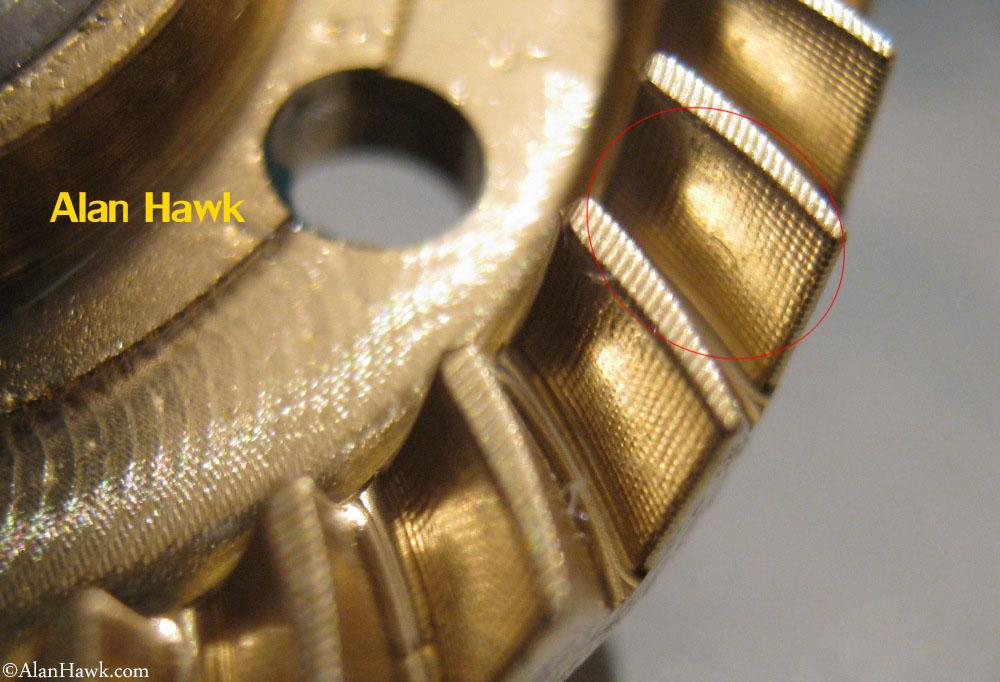

The highlight of the Clash's features list has always been the gearing, which is a machine cut brass drive gear and pinion in 6000 and 8000, and a machine cut aluminium alloy drive and a brass pinion in the smaller sizes. On paper this is a big improvement over the cast zinc drive gears found in the majority of Penn's spinners, including the Spinfisher V series (SSV).

And it delivers what it promises. The drive gear of my reel shows an excellent wear rate relative to the use I put it through. On an imaginary gear durability scale of 5 where 5 is the highest longevity, the drive gear of my Clash would be a comfortable 4. Again let me remind you that this gear type is only found in the 8000 and 6000. Don't draw any conclusions about the smaller reels which have different gearing.

See this micro grid pattern on the teeth of the gear? These tiny indentations retain lubricant for a continually lubricated operation. That should reduce wear and give it better service life than a similar gear with a smooth surface. Good job on that gear.

The pinion is also machined brass, and I found it to be well made, wearing nicely, and indeed a fitting companion for the drive gear. I mentioned before that the reel is tight to spin, but when it comes to smoothness (quiet fluid running) it is one of the smoothest running reels I've used short of the premium category. It doesn't lose that smoothness with use, and the gears maintain their precise meshing feel.

The pinion is mounted on two sealed ball bearings sandwiching the anti-reverse clutch. This area has a great effect on the free-spinning of a reel, and this is why Daiwa initially put their magnetic seal there and why Shimano use their hydrophobic paint in this area in freshwater Stellas. With two rubber sealed bearings here, Penn has created redundant tightness in the action of the Clash. I welcome sealed bearings in the line roller, and can tolerate them on the drive gear shaft as means of keeping water out, but two of them in the pinion assembly is just too much, particularly that the pinion is already double protected by the rubber seals shown earlier. This is not a fully sealed reel and if it gets heavily drenched water will find its way inside from other locations, so sealed bearings here only make the reel tight for no good reason. Regular shielded bearings would've been better.

The clutch is a common design with plastic V springs (red arrow). This exact part is one that I find a lot in OEM reels, and Penn uses it in the SSV. Does its job alright and I didn't get slippages.

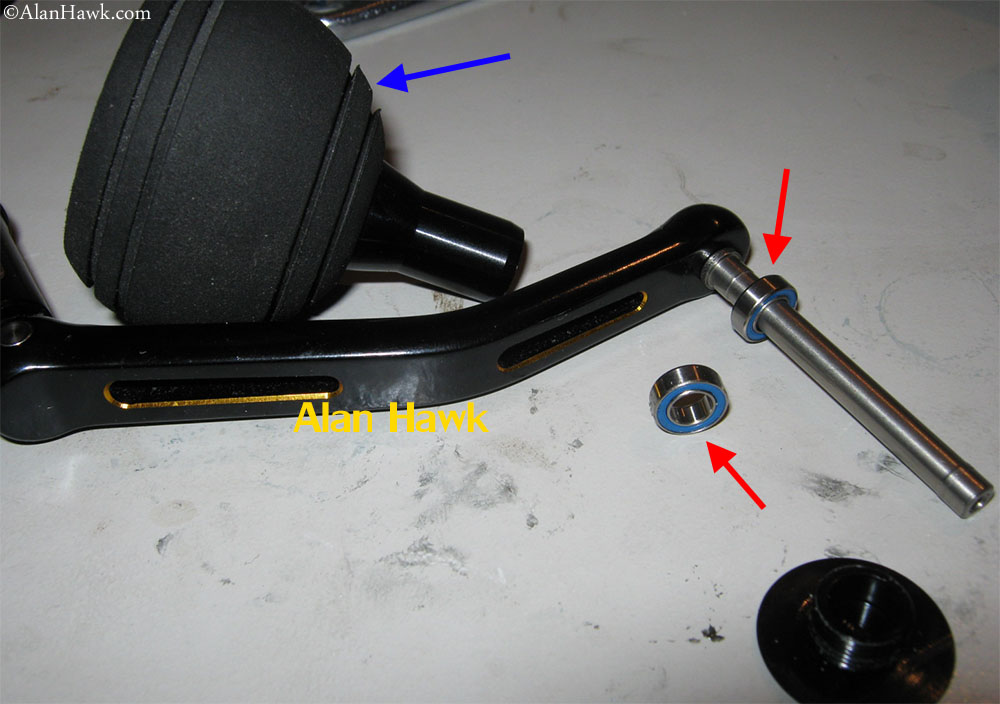

Finally, the handle's knob runs on two sealed bearings (red arrows). The black grip itself is covered in EVA foam just like that of the Daiwa Catalina. Felt good in my hand and was easy to clean of bait bits and blood.

Now let me sum it up for you. The Clash has two major issues in the vital line roller area, and an almost harmless -yet ridiculous- fault in the spool bearing design. Since the line roller problems can be fixed with a washer and finger adjustment, I'll pass it as a working reel that is not a blacklist contender. Still, even with the issues dealt with, the Clash just doesn't make sense to me and it falls short of the competition in my opinion. This Penn has a powerful gear train indeed, but the Spheros SW has the same gearing of the flagship Stella SW only with a different coating (global Spheros SW, not JDM). The Clash is as tight to spin as the Spheros, except that the Spheros SW is fully sealed and the Clash isn't. The Clash is more expensive than the equivalent size Spheros SW, heavier, doesn't cast as well, and most significantly in my book doesn't have the power transmission efficiency of the Shimano. Don't take my word for it; get a Clash 8000 next to a Spheros SW 10000 (which happens to have roughly the same gear ratio), load them up so that the diameter of both spools with line is about the same to equate the retrieve rate, then play the same jig with each reel for 20 minutes and feel the difference yourself. The Spheros requires notably less energy to do the exact work the Clash does.

Someone might make a case for the Clash by saying that the Spheros SW has a plastic rotor and components, but these are people who never actually fished those reels and probably just sit home staring at them then conclude that the metal must be better

Had they actually used them they would know that properly designed parts will do the job whether they are metal or plastic. After all testing a reel in real life fishing conditions kinda beats sitting on your bed and thinking deeply. In conclusion, I make probably 15-20 reel recommendations a day in this mid-priced category, and right now I can't see a reason why I would ever recommend a Clash to a reader over a Spheros SW or a Cabo PTSE. Well, except of course if his criteria were mainly a reel which has the country of manufacture printed on a tiny sticker that's well hidden! Had they actually used them they would know that properly designed parts will do the job whether they are metal or plastic. After all testing a reel in real life fishing conditions kinda beats sitting on your bed and thinking deeply. In conclusion, I make probably 15-20 reel recommendations a day in this mid-priced category, and right now I can't see a reason why I would ever recommend a Clash to a reader over a Spheros SW or a Cabo PTSE. Well, except of course if his criteria were mainly a reel which has the country of manufacture printed on a tiny sticker that's well hidden!At this point the review is over, and the following is in anticipation of the circus that will sure begin once the review goes around. Be prepared for a lot of hysteria and misinformation, pseudo-science garbage, highly motivated shills declaring keyboard jihad, testimonies that the Clash is the best thing since the invention of thongs, or how I must have been sold that illusive prototype that keeps getting sold to me by mistake year after year after year. And while I don't believe that anyone is stupid enough to still do this, there is always the potential that someone will tell you I'm being paid by their enemies or that I have a grudge against Penn employes because they are all extremely handsome and I'm not.

It gives me no pleasure to end the review on such a negative note, but it needed to be said since my last experience with that company was quite the jaw dropper. 3 years ago I reviewed the flawed and falsely advertised SSV, highlighting among other things the low quality gearing, falsehood of the "watertight" claims, and the bogus advertised weights, and sadly the review was met with a backlash of panic and gutter tactics that spanned the whole range from personal attacks to outright lies. Eventually Penn backpedalled the watertight claims, admitted the false weights and corrected them, and while they stopped short of acknowledging the gear issues the web is now saturated with user complaints about the gears that any further denials are simply futile. They only changed direction after I had to engage them for days responding to their claims on a forum I used to post on, culminating in a sad attempt by them to circumvent the truth, which I captured in a screen shot along with my response to it

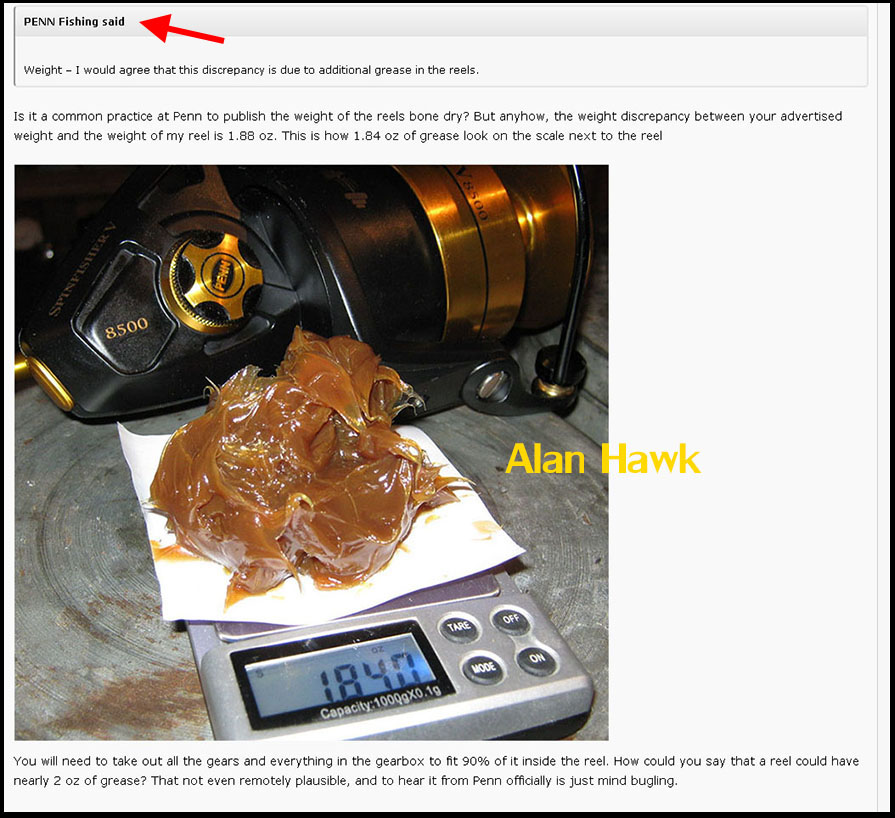

That's what I had to deal with. People who are willing to claim that a reel has nearly 2 oz of extra grease to avoid admitting that they advertised bogus numbers. And while someone could've innocently imagined that 2 oz of grease could fit in the reel, it still shows a mentality hell-bent on denial and claiming that I am wrong without first taking a moment to check facts or consider the probability of what they're about to claim. Just chose a quick example to prepare you for what you might hear, since I no longer engage that nonsense and basically leave everyone to believe whatever they want. Hysterics aside, my sincere advice to Penn is to fix the faults then drop the price considerably so the reel would have some viability. It's a solid performer, but at the current price it has absolutely no place among the much better and cheaper options from competitors.

Not sure what my next project will be. Playing with a couple of reels now and eyeing a couple more, no idea though what or when. Keep watching the News page for updates on what's next, and if you need me I'll be in the balcony listening to Hayley Westenra and eating chocolate. Just holler!

Tight lines

Was this a good read? Please click here

Alan Hawk

January, 25th, 2016

|